-

Posts

5,450 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Funny - i've never heard of their popularity with NOS guys. Turbo yes - known for its intercooling effect on the air temp but in a NOS motor by the time the temps are excessive the water would have been well gone. Rolls Royce used it to good effect with the supercharged Merlin engine - but that had intercooling and 130 octane fuel - all the tricks, water was the top up extra! Personally I believe it's a bit of a band-aid as it a) takes up volume that could be fuel and b) it doesn't burn so is taking up space........but that's just me I guess LOL!

-

LOL - 1371cc with RS flatties and Squeeze isn't exactly a mildly hopped up Blandit!

-

RS 38s on an 1100 slabside or 1200 blandit - which rubbers?

Gixer1460 replied to Dezza's topic in Oil Cooled

38mm carbs have same inlet OD whether RS or BST so both will fit 38mm rubbers. They will easily go into 40mm rubbers (obvs) just need more clamping or stretch a bit of bicycle inner tube over the inlet OD to take up the gap a bit! -

May be of assistance with OEM systems but aftermarket ECU's can reset the TPS within software - it resets rest and WOT positions. Remember the TPS is effectively only checking the body it is mounted to, so physical butterfly balance across the rack is vital.

-

So you are essentially looking for stock Suzuki pistons ? Oil or water cooled, 600, 750 or 1100? Must be thousands lying around - i've got a couple of sets (GSXR 1100K) but can't say what condition they are in - probably need rings!

-

Wonder if the 'engineer' doing the drilling said ' oh bollocks' when the drill chuck hit the exhaust port.............and did he fetch out all the drill shavings - Hmmm what do you think!

-

I think we all should just agree to disagree and do whatever the hell we want to do! Please note that 'I' have never claimed they are good or bad, just that I have them fitted and that they have done no damage to my motor. If you do not want to fit them - don't and leave it at that!

-

Consider this ...... All of the oil cooled family and most of the air cooled ones have crankcase fitted restriction jets fitted - pressure before probably 80 psi, after maybe 30 - 40psi. This is all a plain bearing requires to work properly. Due to this restriction and the 'up the stud' transfer method, i'd guess it would take a matter of seconds for oil to arrive at the cams - they rely on surface film of oil to prevent / minimise metal to metal contact. Now, 4 psi pressure has been quoted in the cooling circuit which as it is independent of the 'pressure circuit' flows unrestricted and reaches the head far quicker - I believe its pressure to be higher, volume certainly is, which when restricted by the cooling jets over the combustion chambers must increase its local pressure by an amount? So there may be no significant effect, but any oil that gets to my cams a) quickly and b) with some pressure behind it, is ok by me! And if you are curious, I have 85mm bores and a +5mm stroke crank and still run oil up the studs - secrets, secrets!

-

Nothing hidden - all was visible for all to see! Nothing bling, and nothing there that didn't serve a purpose! It's not a competition bike - if you read the statement correctly - its a STREET BIKE ie. MOT'd, Tax'd and Tested - when i'm bothered! And the last statement proves you don't know it and that it is still running without any replacement parts although it is currently not in max. output configuration!

-

Query - absolutely stock head or have the valve guides been replaced? If the latter, they maybe to high and are getting clouted by the spring retainer - likewise if using a Higher lift cam - same effect. Not much else unless the guides are badly worn so valve stem is knocking them out? Lots of oil / assembly lube whilst fitting them - difficult to damage really unless seating them with a mallet!

-

Psssst - the most powerful GSXR based proper streetbike in Europe has top end link bars...................just sayin' like!

-

A footrest cracking is an inconvenience - a broken front brake lever is a tad more serious! I've snapped and bent OEM levers ONLY by throwing the bike down the road - any other time and IMO, makes them not 'fit for purpose'

-

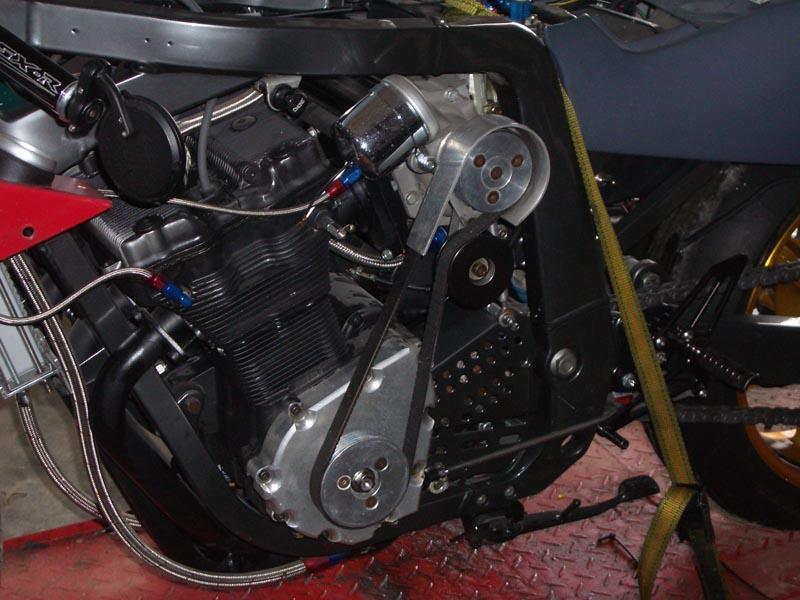

Interesting combination abit overly complicated IMO? Question why not add banjos or 90 deg. elbows, direct to the aeroquip and avoid all the multiple fittings? How does it all fit with the exhaust - all looks a bit tight ie. can filter be removed with headers in place?

-

Further to Clive's post above I found some other pic's of that kit that I thought were DIY - don't have the feel of a product - rather something built in a shed? They may be of some use.

-

The alternator looks at the voltage that is applied to it from the ign. sw. to determine its output. The wiring from the battery to the ign. sw. and back to the alternator induces a voltage drop down to, say, 12.2 volts so the alternator ramps up its output potentially overcharging the battery. So with the relay, you are connecting the battery direct to the alternator with less voltage drop so less chance of over-charging.

-

-

Good luck - i've only ever seen pictures, never in the metal. They are rare in the USA so this side of the pond is anyone's guess?

-

I think thats gonna need some persuasion with the heavy engineering adjustment mallet! Is it welded yet or just pressed - could have pulled with the welding (if it was!)

-

Robinsons Foundry - mention OSS membership and get a small but appreciated 10% discount.

-

As i'm no physics major i'll ask the Q - does the magnet strength have any bearing on the eventual output? I see that a lot of the hybrid / electric vehicles use high efficiency motors having neodymium magnets in place of the old ferrite magnets. All of these rotors are a) over 35+ yrs old, b) heavy c) magnetically 'tired' - so I was thinking, break out the old ferrite and add back lots of new neodymium bar magnets and re-glue...........would it work?

-

'same for all OSS engines' is a broad sweeping statement and NOT factually correct! The Hippo engine was based on the 1127 cc engined GSXR family series - nothing else! If the crank is unknown then you can use the references stamped on the cases to give one half of the bearing sizing information but the crank journals need to be measured accurately to determine the ID bearing size required. Then you'll have to use a sizing chart to determine the correct sizing - there are 3 sizes available for the mains and 3 sizes for the rod big ends - so lots of combinations. Unlike with cars, lorries etc. bearings are generally only available OEM - no aftermarket suppliers, no shortcuts!

-

I'm struggling to see a 'first generation' frame there! More akin to a pre-prototype frame, factory built to go racing with a GS motor full of magnesium, one off, ltwt. castings - as a GS thou motor just will not fit into a std production Gen 1 GSXR frame as we all know! The XR41 frame looks more like a Harris with square tube...............could even be steel for all I know LOL!

-

A rising rate FPR works like a Rising rate suspension linkage which increases stiffness the more it moves. The RR FPR's increase pressure in an increasing ratio more than the boost being applied ie 1lb boost will get, say, 1.1psi fuel pressure, 2lb boost will get, say, 2.2psi fuel pressure etc. These figures are applied on top of the baseline fuel pressure but the mapped injector opening times remain exactly as when mapped NA. The downside is boosted engines require fueling that isn't necessarily linear so could be lean or rich with no way of tailoring it exactly. Also the pump has to supply sufficient flow for NA flow, then added boost pressure + the additional increase BUT generally all pumps decrease flow the more pressure they are required to provide, so a pump that gives, say, 200ltrs @ 3 bar for NA but at 10lbs boost might only flow, say, 150ltrs however if a RRR is used the now extra 11lbs pressure could result in 140ltrs ! ! just when you need the most flow! Proper mapping keeps a constant FP across the injector (boost pressure increases FP but air pressure is the same so its equal) and increases the injector opening period to match actual demand -- this is the correct way. The RRR way is generally used by people who want to use a non mappable ECU and with ratios of up to 1.7 : 1, the pressure increases on the pump get daft ie. 20lb boost will require FP of 43 + 20 + 14psi = 77psi which will nearly stall most pumps! Hope that helps ?

-

Yes - but they do go extremely well with a younger generation engine in the hole!

-

If those are figures for an H4 LED headlamp I think they are a bit pessimistic (unless that is a measured figure) as the one i've got in my daily is about 9w dip and 18w main - each side is 3No. Cree type LEDs, both sides turn on for High beam! Don't forget the Horn ! Saw a bike that died everytime you beeped the horn - voltage / current was so marginal that the horn tipped it over the edge LOL!