-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Thats a shit load of work with a pressed up crank not to say expense!

-

But fully agree with the above sentiment LOL!

-

I just hate everyone i've never met then hate them some more when I do - nothing personal!

-

They had moved on from tractor technology by then, tacho's were electronic.

-

As 4x Dyna 2000 user with no problems, I hate to concur with Badger but the Ignitech does seem feature rich for lower cost - I guess it's the march of technology ....... the Dyna is getting on for 20+ years old now!

-

Is this site turning into "Suzuki Ownership for Dummies" ? If you don't know what you are doing - buy a Haynes or Clymer manual and read it - then read it again, then tackle a job and then if you get stuck come and ask a question!

-

That's barely a controlled leak! LOL! My daily 55hp 'onda has an 8mm tap!

-

Sort of related - I built a GSXR head onto GSX barrels and gasket around the chain tunnel was marginal so we welded in some 6mm ali before it got decked to provide the extra real estate for copper gasket. Oh and due to the stroke difference we had to add two extra links to the cam chain - normal roller not Hyvo though!

-

Just to stir the pot a bit for the DJ haters DJ parts have a lifetime warranty - if they are worn, send them back for free replacement - Why won't Suzuki san do the same thing...........got a worn out GSXR here?

-

That is a confusing statement - a turbo doesn't generally have what are called 'downpipes' just a manifold / collector and this is NOT the place to mount a WB sensor. Anywhere downstream of the turbo outlet is ok as a lot of the heat / pressure is dissipated, just try to keep away from the outer end of the dump pipe - if you have a full exhaust you are in clover as the issue doesn't arise. Orientation is important also ie. between 9 and 3 o'clock is ideal.

-

Usually these guys will be able to help - http://www.allensperformance.co.uk/

-

Of course it's possible, most of the turbo builds on here are carb'd installs - probably less than 25% use EFI as well. Check the site - most things have been discussed.

-

That's mental - they sell a battery they know to be shite, only give a 90 day warranty because they are shite and end up having to replace them because they don't last longer than 90 days - that makes a lot of financial sense on there part! Surely a £10 / $10 more expensive battery that doesn't fail would make money rather than lose it ?

-

I suspect Bimota put a bit more design / engineering into their builds than 'a talented guy in his shed' (that is a 'tongue in the cheek' remark for all you literals!) The SB6 came with a slabby engine - will it take a slinger? If it does, then the head fixing must be flexible which would then imply its not a 'structural' fixing. And this would leave the whole engine supported via the two rear mounts - that I really wouldn't like. This is a personal opinion and don't care if others do it this or that way - for all I know, there could be shed load of plate between the frame rails as bracing negating a load bearing engine that was designed to be in a cradle frame!

-

Those poly-vee belts do transfer quite a bit of power - pretty much universally used on modern cars with high load alternators, power steering pumps and air-con compressors, so why make extra work for yourself?

-

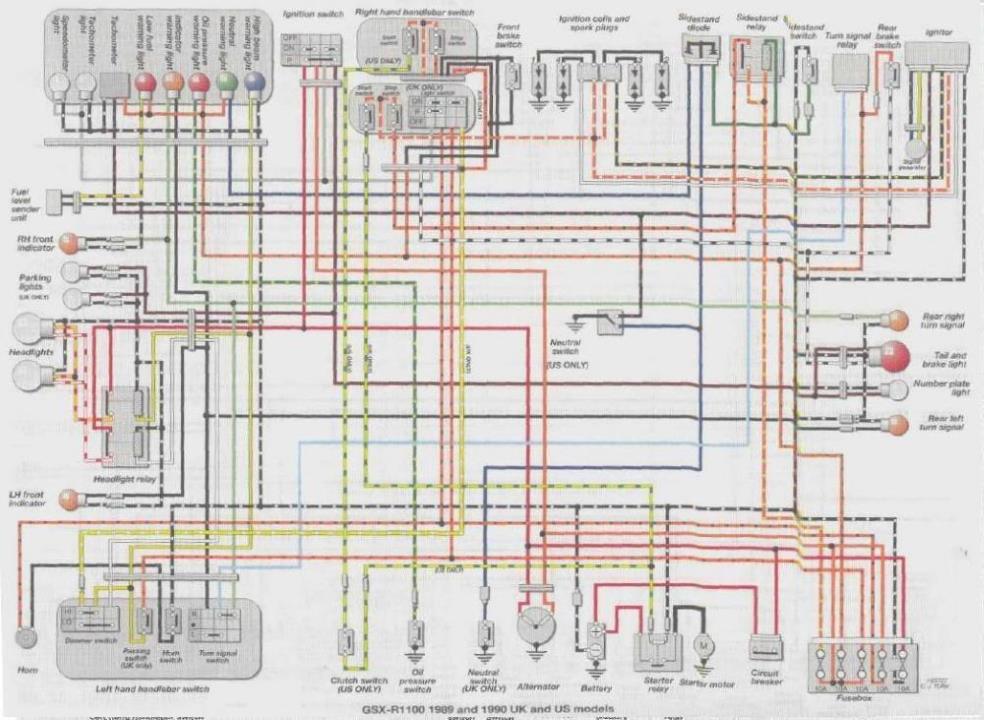

Looks / sounds about right to me, although one change i'd make is to lose the 'main fuse' between battery and alternator. If it pops, you wouldn't know it until the battery dies and running an alternator without a battery connected really doesn't do them any good. If you want a 'single main fuse' stick it in the line between ign. switch and the fusebox / M Unit so it kill everything - as it should.

-

Good move retaining the airbox - solves a lot of jet faffing around when fitted to alternative motors. Won't solve ALL the problems but does help CV carbs work as they should.

-

In the 'Rock, Paper, Scissors' of life - scissors always cuts purse strings of Projects - at least you've got something else to keep you occupied!

-

-

Interesting - I thought 30mm was about as big as you could go without recentering / spreading the guides or you run out of seat by the time they are recut?

-

With a hump on the starter cover I suspect a GSXR11 (but which one ?) or Blandit. Re : The Head / frame mounts - not sure I like them due to using a non stressed member engine in a stressed member situation ie. it's not designed to resist those loads ............ it probably will for the low mileage the bike is likely to travel - doesn't make it right though + you are buggered trying to fit anything else in there - 750 (nah) 1052 or 1127 (different ht.) stroke'd motor (no chance!) - all subject to how the head fixings work - solid fix or rubber grommets LOL!

-

Very deep for a Monday morning LOL!

-

36mm's will be more than big enough for intended use (will retain enough bottom end and breathe well enough to support 150hp)

-

Possibly due to the lack of use the piston rings have 'gummed up' / stuck in their grooves? If you want to sacrifice a sump full of oil, you could try degumming them by taking all plugs out, set crank so all pistons are at same ht. ie 90 deg between 1-4 and 2-3 TDC and fill cylinders full of petrol / gas and leave for 24hrs. The fluid will leak through and around the rings and into the sump which MUST be drained and refilled inc. filter with fresh oil. If any petrol remains in the cylinders, disconnect the coils so no sparks and spin engine over on starter to eject through plug holes - a rag over will cut down on fuel everywhere. Then new plugs back in and start to see if any different. And yes the compressions are low - should be over 120psi even with a cold engine and they shouldn't vary by no more than ideally 10% - yours are 33% ! ! !

-

Summat strange going on as should be third iteration of the 750 family - 1st GS750, 2nd GSX 3rd GS ES? (or was the ES just a remodelled GSX?) Bit of a Frankenstein whatever! As for buying parts - good luck as the parts kid will give you a 'blank thousand yard stare' with that concoction LOL!