-

Posts

5,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Maybe GS1000 rubbers might work or are they bolt on?

-

Or sticky throttle cable

-

Unlikely to blow-by as there are 4No holes, all at 90 degrees to each other.

-

Don't take as gospel but I think the 1100 is 21 pins and 750 is 22 ? ? ? Brain is old and memory fading + i'm not near a manual presently!

-

Waste of time and due to proximity to cyl. head or upstream of turbo (depending on style chosen) would likely fail in short order! A single sensor after turbo is usual placement but be warned if running a shortie dump pipe the sensor can be confused with atmospheric oxygen due to sensor being close to exhaust exit! Try not to fit before turbo as pressure and elevated temps not good for them!

-

You do realise that if you get it 'bob on' for sea level riding, with the added weight / drag / power loss at altitude - you might not get home again? Won't comment on potential jetting as there are far to many variables in play. But that outfit and your situation almost cry out for an EFI conversion - self adjusting for altitude!

-

Draw through comments all fairly valid IF using a carb solution! Most, if not almost all go away, if you use an injected solution. Plus Draw Through is Oldskool Cool!

-

I've had 4 Dyna 2K's - still have one on my 1460 and never had a problem but others have - maybe the far east production had an effect ? But the Ignitec is newer tech and reports are good about them plus made closer to home if there is a problem. Haven't used one or even seen one fitted so thats the limit of my recommendation!

-

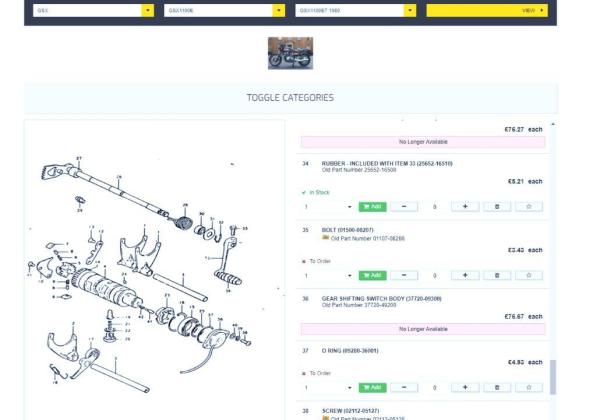

I think (believe) this one (in the centre) to be either GSX750ET or GSX1100EFE. The one on the right is simple Neutral only. If the drums do rotate in different directions its sort of clear why you don't get all the outputs ( i'm almost surprised you get any!)

-

Could try 'Turbo Dynamics' down in Christchurch, Dorset. They are rebuilders and have always had mainstream stuff for me, usually in stock.

-

I was just thinking that myself. The arc the shift drum pin takes is usually worn into the 'switch' and if you are lucky there might be wear spots for 2,3 and 4. First and 5th should be obvious as last places in the 'track' in either direction. Drill through with 3 or 4mm drill and epoxy in some 3 or 4mm brass rod, flatten off over sheet of wet & dry (engine side) and solder wires to brass on outer side. Once done, coat with epoxy to seal. Don't forget all the outputs will be to ground, so bulbs in the indicator should have common 12v+

-

Blandit . . . . at a guess?

-

Which is fine if you never want anything other than spring pressure boost otherwise you have to add a bleed valve or solenoid valve into that line to bleed pressure to 'fool' the WG actuator into thinking the higher boost is actually lower. And in answer to someone above - actuators are very rarely bolted directly to turbine housings, even where internal WG's are used, the actuator is usually bracketed off the Compressor, or fixed on a short stub pipe to avoid heat AND facilitate mounting!

-

Could be anything these days if no markings! Carillo only laser etch numbers - no stamping. Chinese 'cheap' copies use bolts marked ARP . . . . . but aren't. You paysyer money and rolls the dice!

-

I did, and it had the gear indicator, that's why I assumed an 1100 ET did also! Obvs not it seems!

-

-

I say . . . . . best to check !

-

Its . . . . . . Its . . . . . . . . A CAR ! ! ! Same rules apply - get it as high above static oil level as possible but of course that affects C of G which can have more side effects than desired in 4 wheeled 'Ltwt' vehicles. Hope the sump baffling is good - dry sump would be ideal of course!

-

Sounds like a draw through install - if so, they never need a pump, gravity drain is easy to achieve. Just keep drain line back to cases above static oil level. But that far back could introduce lag into the delivery, most would have the turbo behind the cylinder block.

-

I assume that there is a FPR somewhere? 'Most' installs have the regulator after the injectors - at the rail outlet or soon after. This negates the 'path of least resistance' thought as the whole rail will be at pressure, at all times. If fuel exits, say, between 3 & 4, the pressure will be the same but fuel 'may' stagnate as there is no flow past it - although the effect should be minimal as it will be used and replaced through use. I have two rails with 8 injectors - in bottom left, loop from bottom to top on right, with FPR on outlet top left - no problems with differential flows or pressure over injectors. If one cylinder is persistently showing a lean condition it might be a dirty or sticky injector? A clean and flow test may be wise as its unlikely to 'get better' with use!

-

I'd disagree! The fact that an EFI system generally can allow accurate fuel delivery - more or less - at any rpm or load and that ignition timing can be dialled in, also to those parameters means detonation can be minimised to the extent of being virtually un-detectable. It may still occur if a bad batch of fuel is used or climatic conditions are unfavourable but its unlikely to be engine destruction type det. As noted above, det. largely occurs around peak torque and as turbos can produce such wide torque bands the option to take out or add in timing in particular areas will reduce risk. Personally, this is one reason I ask a dyno tuner to step tune when developing a MAP - go up rev range in steps and stop at each whilst allowing figures to stabilise and optimise fuel & timing there before moving to next step. It puts the engine under a LOT of load for minutes at a time and most tuners don't like doing it but I figure I don't ride at max rpm and max output at all times so I want these areas to be optimal not just at WOT!

-

Of course they have a VIN! It may not be the 'modern' 17 character one - because they were from an era when it wasn't required! The letters and numbers on the headstock are the chassis number - that is what the vehicle registration uses for VIN.

-

Would new seats be required? - GSX seats as std can take pretty big valves without changing. But agree on the stem size thing - I wasn't sure about relative diameters. It could be possible to 'sleeve' the oversize GSX guide down to Busa stem size - its involved and needs the correct machinery ie. a Serdi but could be done. I doubt it would be cheap though, but neither is making custom guides!

-

Is It? I mean firing order? Normal order is 1-3-4-2 and will have same characteristics as you describe?

-

would the bike shop be 'Bill Bunn Motorcycles by any chance? That hourly rate is about the norm these days especially for London!

- 18 replies

-

- gsx1100

- suzuki gsx1100

-

(and 2 more)

Tagged with: