-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

That'll teach you for not reporting the outcome - children have enquiring minds - full gory details pls.

-

Who actually knows? It depends on what rpm you are trying to achieve and for how long you want it to live? I've got a full billet EN40B 65mm stroke crank with some mods that should make it stronger - it is designed for turbo use ie. lower peak rpm and I wouldn't want to turn it more than stock redline, it had a twin that went into a sidecar outfit - those guys like rpm but how long it lasted is anyone's guess, maybe a race, maybe a season? Maybe if some steel caps could be built into the cases to minimise any crank flex, reliability at rpm may be improved?

-

Must be possible - these cranks in ProStock motors have 14k redline - no way they aren't balanced ........... 1850cc as well!

-

Don't think i've heard of anyone pressing up their own crank before - good job. Bit of weld I spy on that S/C gear? Is the rest fully welded? Are you going to bother with balancing - shame not to!

-

Query - could you remove spacer from below, drop the top yoke down the stanchion and have the clip ons above the yoke GSXR1100 stylee - spacer could then go above yoke and be made to look halfway decent?

-

Nice Fab skills - I see now why turbo required - someone has bolted two wardrobes on the back - there's ya problem LOL!

-

Isn't that an oxymoron ? LOL! Turbo assistance on a tourer is a bit pointless unless towing a caravan as well? I'm a big fan of HD studs - I used them on NA high comp which probably has higher cyl. pressure than low boost turbo? But people do use stock waisted studs with turbos and they work ok - just not my flavour / preference.

-

Clive - Sean never really cured the fuel starvation situation with that bike nor the Spondon Kat. It didn't help using the same pumps for the NOS systems. PW was using so much fuel pressure, fuel would drip from the carb mouth at idle and flood entirely after a few seconds - lots of rpm just about kept it running. For 'mere mortals' with less extreme installations, the bigger bowl may be of a benefit with or without a pump. I agree on the S&S though - Huge float bowls - shame their fuel metering is so bad!

-

I see from above you are using an HSR42 carb - unfortunately, whilst they are a great carb they do have a pitifully small float bowl which shows up on usually turbo'd applications............ Hardly Abletoo's don't seem to suffer LOL! There is a float bowl extension available that may help? A pump will get over the problem but at high power most LP pumps still struggle to keep up with demand! Picture from Mr Turbo in the US.

-

Is this, cams in or out? If in. my 1st thought was valve pockets but they look big / deep enough (providing its not a 'stupidly big' lift cam). Other than that I can't see anything else that could interfere .............. its not a loose can chain in the tunnel is it?

-

I'm guessing the top one is stock 38 and lower is the Factory Pro kit needle? Query - does the Short needle fit the slide and does it stay in the emulsion tube at full lift? If it does then it may be how Factory Pro engineered the fuel flow ie. onto the Main much earlier? Ifit comes out of the tube completely @ full lift i'd not be inclined to use it as it could jam open at WOT - not good! It could actually be a 36mm needle?

-

Not the usual route but I used -10 with 90's .............. probably not the neatest way and the 90's acted as my lock stops LOL!

-

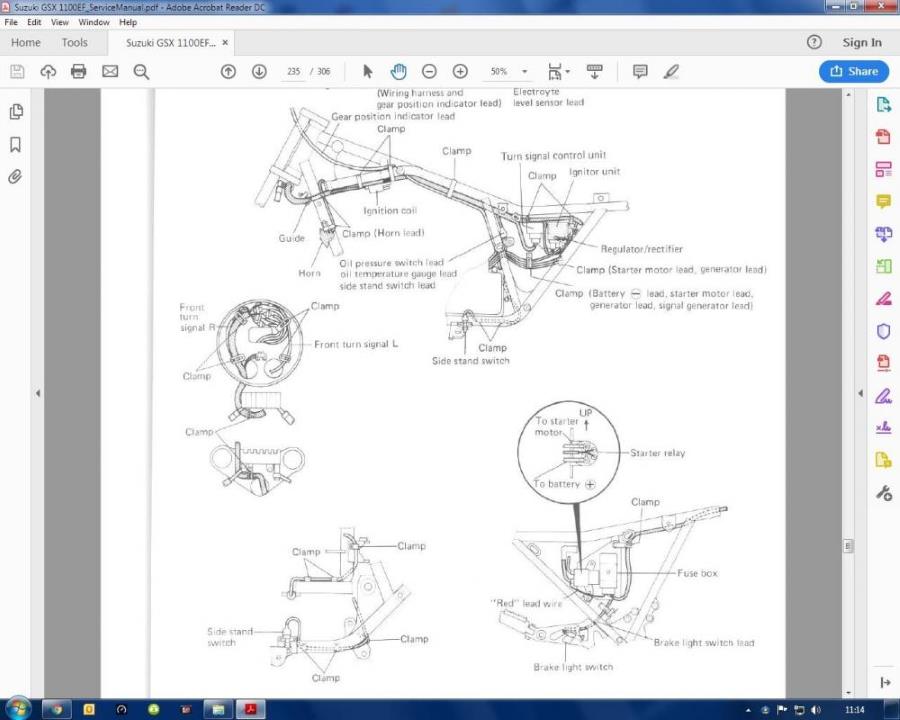

My Kwak based trike has a similar battery monitor that should have a graphite rod that dips into the acid - long since disappeared - so I just pushed a piece of SS welding rod through one of the filler caps connected the wire an my light went out! Wonder why Suzuki chose to call it a 'fluid level switch'. Still think that is a way of replacing the 'dip rod' - if you earth it does light on dash go out?

-

Looks brutal but that chain needs some love!

-

Can't remember what the Bl/Gn wire is from / to ............ but that resistor ISN'T standard!

-

Yep - the R/R is trying to charge a goosed battery - not good for long R/R life!

-

Bodging of the 1st order! That'll be interesting come chain & sprocket replacement time!

-

Wouldn't that have been the obvious place to look / ask first?

-

Site does have a 'Search' function - suggest its used first - RTFR ...........Oh, a Hello or an introduction is generally appreciated.

-

Bollux - simple physics - downward facing connections will not drain the cooler unless sump is empty.

-

And adding a 45 deg bend will put it straight through #3 exhaust! You need a 12.5 deg bend - not available for larger hose! I would be either straighten the #4 pipe more vertical, put a dent in #4 or re-centre the cooler to move the pipes away from the exhaust!

-

You can but I don't see what advantage it will give unless you want to kick the pipe out forwards?

-

-

That would also require re-making all the exhaust pipework - somewhat more involved! A standalone gate may be easier. But if the filter mounting screw can be removed then a re-made adapter with M20 on the engine side and a M16 thread on the filter side to allow a Yamahha thin filter may be the best overall fix?