-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Apologies - air and oil cooled nomenclature confuses the hell out of me! Especially when GSX can be air or oil cooled! Try this one..... https://www.suzukiperformancespares.co.uk/product/suzuki-gsx1100-1133cc-cometic-head-gasket/3303/ A complete set always makes sense and Vesrah are ok - but most aftermarket valve seals aren't up to OEM standard and tend to harden / split / crack too soon - pays yer money and takes yer choice!

-

https://www.suzukiperformancespares.co.uk/product/suzuki-gsxr1100-1109cc-cometic-head-gasket/5078/ 78mm is std bore for a 1127 motor or 1 or 2mm overbore for a 1052 motor (I Believe?)

-

Probably best aftermarket gaskets you can get - used by race teams the world over!

-

Is it an air cooled 'G' or an oil cooled Hippo 'G' - is 1st question?

-

That seems to be the going rate for H/Gaskets whether OEM or Cometic - any other will be 'at risk' as they cost because they work!

-

Looking at the fiche drawings, these pumps 850 / 1000 / 1100 G do look like they are an integral unit - not like the 1150 models which are disassemblable (i've had a couple apart so know they are) The 'G' units may be riveted together and I guess ' no user serviceable parts' denotes no spares available. The two units look dissimilar so no swapping possible! Testing is usual only with complete motor - pressure isn't high even when healthy - personally if there is evidence swarf has come anywhere near the pump i'd be looking for a good replacement!

-

And yours is reversed!

-

+ the 'M' carbs (40mm) are a PITA to set up unless induction is absolutely stock! A repair will be likely cheaper than a replacement head. Using a Blandit engine in a GSXR will be a disappointment with its lower output!

-

I'm struggling here! A 044 is not a small pump (and its amp draw may give your electrics concerns!) and it seems to be fitted within a cylinder with nicely machined ends that all achieve nothing except make it bigger - at a guess, its nearly 100mm dia and 250+mm long? A 044 pump will usually support 500hp - do you need that much?

-

Doesn't make a great difference - it's just an endless loop of wire inside some plastic with connections at either end! It's more likely a problem with the wiring between the trigger and the spark box or between the spark box and the coils, if the coils are wired to power etc.

-

Wouldn't use one of them for that purpose - Intermediate duty cycle means it would likely overheat or seize if used continuously!

-

Just thinking the same - retarded ignition on high boost starts the burn later, which could still be burning into the exhaust phase so overheating valves and nibbling turbo turbine blades. You won't see it on the output but will eventually in reliability!

-

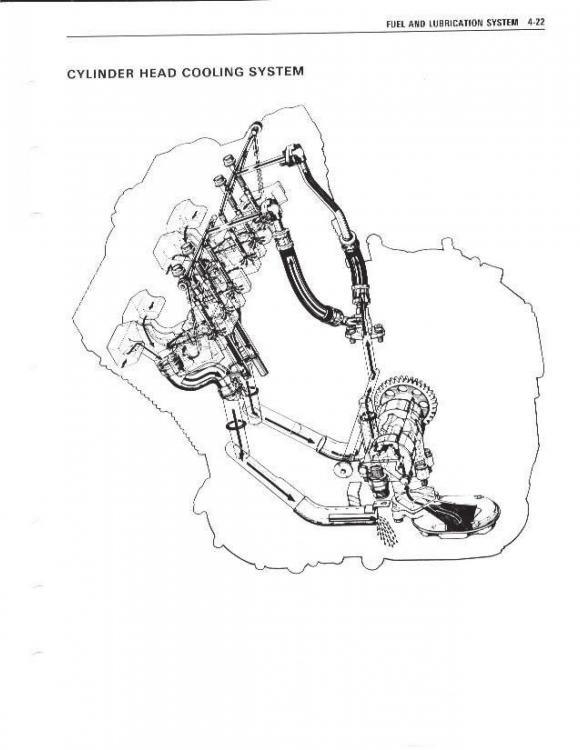

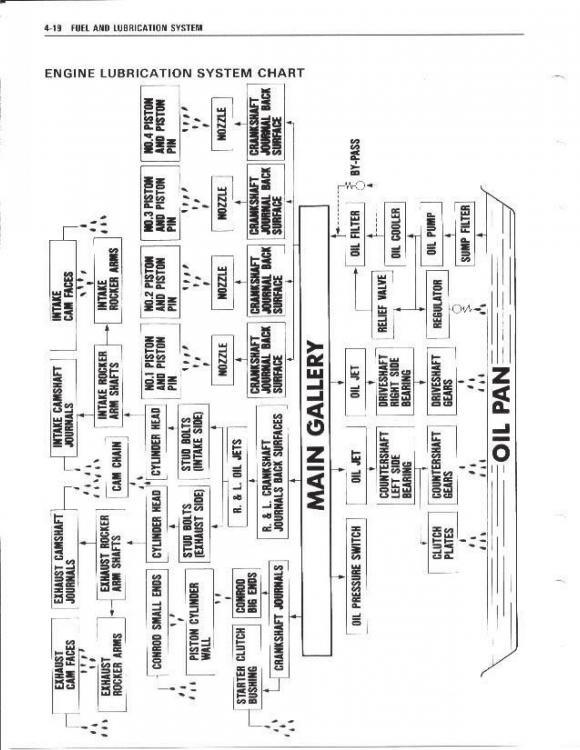

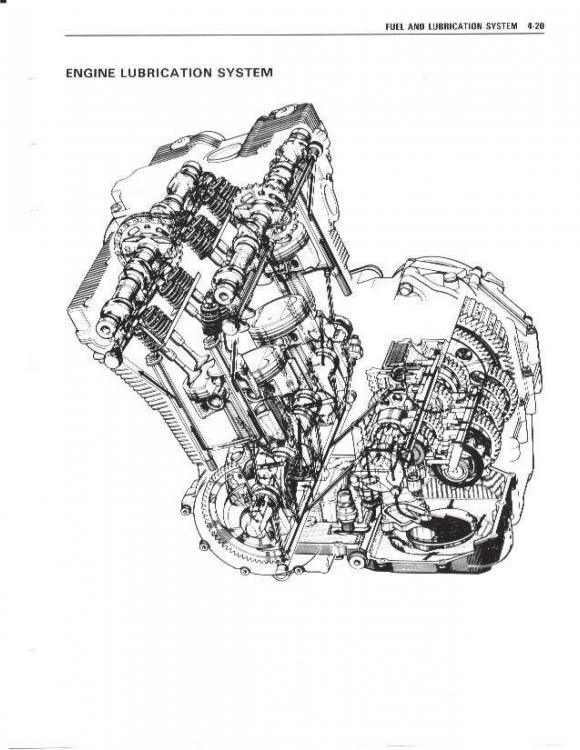

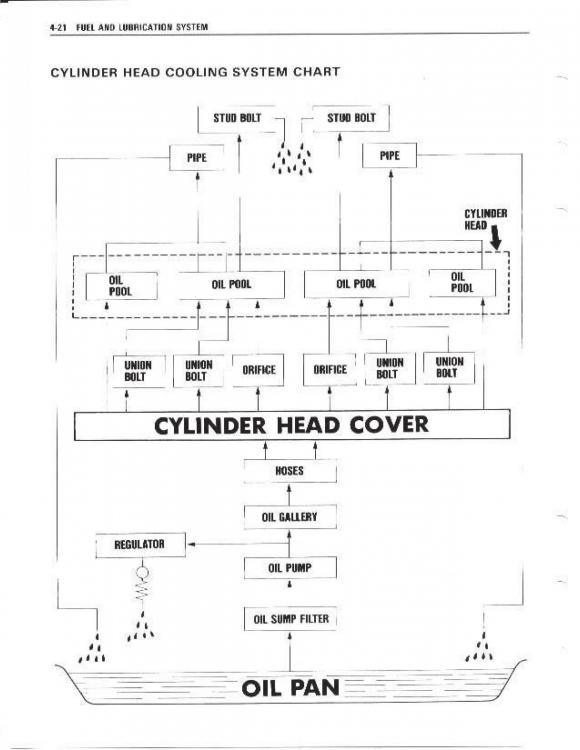

Schematics is easy - see below, but pressures is tricky - pressure at main gallery is quoted by suzuki but not at every 'point of use'!

-

What is your setup and the application you are intending - why using such a large pump? If you do need that pump then a return back to the tank would be advised or you'll need a better regulator - Malpassi for example!

-

Not trying to sound smart but that's because 1100's have 5 gears and 750's have 6! And apparently there is a size difference but I can't confirm as never seen the two side by side. Any o ring that correctly fits the o/d of the switch will work.

-

Would be odd as cylinder studs can normally be reversed / fitted upside down ie. threads same both ends M10 x 1.25 (metric fine)! M10 x 1.0 would be a bespoke thread - not regular.

-

I dunno - I'm facking guessing hence the ??? after everything! Last one's I got were £300 inc boring..............if i'm out of touch - flame me if you want!

-

Is it really that much cheaper? JE hi comp pistons - £450 inc boring? Against s/hand Busa pistons £100 + boring £60? + Barrel surfacing £60? + DOT head £150? - total = £370 and lightly to be sub 11:1 CR? Add in a new set of rings (not essential but why not with fresh bore) £80? and costs are comparable.

-

Used both pumped and non pumped with my Kawazuki - tank was fitted with twin non vac. Kwak taps - plenty flow into an S&S Shorty. Didn't much like the Facet pump - only used it to race.

-

And -6 as that's what I used for the EFI pressure hoses on mine - rubber was just too 'chunky'

-

No you can't as that just forms a closed system! Any crankcase compression wouldn't vent so would lead to oil leaks and potential blown gaskets. Always take breathers to open air via a filter or a catch can as they will breath vapours / oil mist.

-

Part # 09280 - 36001 I suppose you're gonna ask me to pay for it next LOL!

-

-

Nowt wrong with Dyna S - only 4 wires and it's good to go. Good fit with the old ET engine as the ATU is required and that has the deep cover ...... EFE guys have to find those bits to use an 'S'. No performance advantage but you do lose the near 40yr old electronics!

-

Braze over - use someone local or DIY solder could be an option?