-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Does that board have the VR conditioner 'built in' - the v0.4 board doesn't - it's an add on? You'll need it with std pick-ups.

-

Short stroke oversquare engines will rev - the 1100 comparatively is long stroke............in 1100 terms. The internals of a 750 weigh considerably less which helps!

-

If the OEM is working - no benefit at all.

-

I tried telling the SSB boys that waaaay back - no one believed me! I think unless you rely on electronics with delay boxes and air clutches and throttles you have to be killer on the tree 100% of the time, especially with tight dial in's - you snooze......you lose

-

Well that ain't gonna hone or polish out! Std valves are good but they do have an annoying habit of dropping their heads if they get overly hot - something else to check!

-

Most oil cooled exhausts are similar around the headers / frame obviously but the variances come with sumps - some flat, some vee'd and some halved / cut away. Most sumps can be swopped around (with its oil pick-up of course) to fit any exhaust so either buy one that fits your sump or buy sump to fit exhaust.Haven't heard of that Speeduino before - just spent last couple of hours reading the Wiki on it - impressive and quite cheap for a DIY version - I might give it a go. Whilst 36-1 tooth wheels have been used - see attached, the tooth count does get a bit daft at high rpm especially with a VR pick-up....... a Hall device may work better but there isn't much space. I like the on-board MAP sensor that will be ok with a bar and a half of boost but I guess standalone GM 3 bar types could be added in lieu of onboard.

-

It doesn't work like that - 1st turbo running at 50% efficiency feeds half potential boost to 2nd turbo running at 50% and you still only get half potential boost out! It really is better to use one correctly sized and located turbo for max efficiency and minimal losses! Compound done correct way................... And it ends up looking like this......... And no, picture nazis, that is NOT a Yam engine LOL!

-

Why would putting two turbos away from their energy source help? You end up with 2 having crap efficiency rather than 1!

-

Maybe people that don't like Pod filters - K&N's are my preference - have probably never had carbs set up with them - easier to blame a simple filter rather than their own ineptitude or tightfistedness LOL! CV's certainly don't like individual filters - they seem to like a 'reservoir' of air greater than an individual cylinder capacity.

-

Help with barrels

Gixer1460 replied to Mendoz's topic in Water Cooled, V-Twins, Singles and 2-strokes

Possibly pistons placed in barrel to keep right piston with right cylinder, pushed past normal stroke ht. and some damp has got in and caused a bit or corrosion? If it is below the 'normal' wear line, a light hone should take it off. -

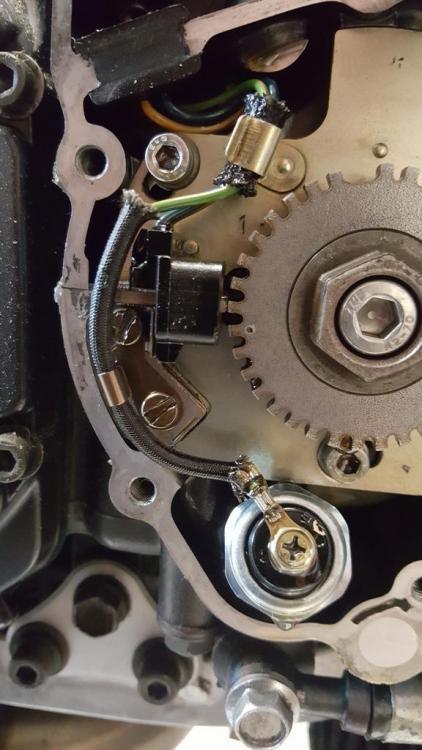

So, it was stuck to the pick-up magnet (steel obviously) in 1st picture and now its not? Did you remove the screw? How could you not notice the 'fairly obviously broken rotor tip' and not pull it off the magnet! Problem is - it may have picked up a weak magnetic field from the magnet and so will stick (fairly weakly) to anything steel it touches. So IF it has fallen down past the switch, there are a lot of steel bits it can interfere with before it gets to the sump! Best drain the oil and if it's not in that then sump off and pray it's there !

-

What do you mean? The void below the oil pressure switch?........................... crankshaft, rods, gears, sump and oil !

-

Have to tell you that isn't an 1127 rotor or pick up plate! Its an earlier 1052 type! And re Piccy above - you'll need the corresponding Spark box and because its a Blandit you'll need the Blandit Ignition switch or a way of 'fooling' the electrics to work!

-

Don't go mad with that - it irritates the powers that be and they'll delete them so you're back to square one LOL!

-

One thing often missed is these were 'usually' used in conjunction with a fairing, at a guess, to provide a fairly still air zone in the absence of an air box for carbs to function better - slightly higher pressure zone - whether the effects can be proven is debatable........ but 'Pops' did know his shit!

-

Not going to get into the 'do they / don't they' debate - but will state a GSXR will not notice the addition of a turbo oil feed - the pump bleeds off between 25-50% of its pumped pressure and flow so a turbo feed is insignificant! Putting more oil into the head cam space isn't necessarily a bad thing with an oil cooled engine IMO!

-

Got to ask - if tight for space at top why not use bottom feeds - cheaper fittings as well!

-

Lifting needles makes them richer - not leaner.

-

150hp worth of air is still 150hp worth of air whether it goes in at 8000 or 12000 rpm! And a stock 750M ain't gonna be able to use 150hp worth of air anyway!

-

Unless you are chasing every last HP then no they are wasted! RS36's will be nicer to use on the road!

-

IMO RS36's are known to work well on 1216 motors to over 150hp and the factory used 38's for racing so i'd say anything bigger would be wasted and even 38's could be overkill for anything much less than race spec use?

-

-

That's the secret - they don't respond well to disrupted air flow - open, ram pipes, small filters etc.

-

Good luck - they are a PITA to set up!