-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Had one on a drag bike and they are fairly idiot proof! Red to 12v side of coils or switched ign 12v, Black to earth and blue and white to the opposite side of coils, piggy backing the extg. connection. Apply 12v to brown wire to make it work.............. not much to get wrong. Do you know if it actually works?

-

Unlikely but did you take the clutch basket out? Could have misplaced it and mashed the oil pump gears on the alt. gear?

-

And don't force it into the hole as that's liable to crack the oil pump gear!

-

Hmmm Bat Flattery and over heated alternator .......................so no!

-

You'd be surprised how often it's not!

-

Basic alternator theory - a spinning coil of wire or a spinning magnet will produce a voltage whilst within a magnetic field or due to a magnetic field . The red is connected to a spinning or a static coil and is the output but unlike the old GSX's that had a permanent magnet glued inside its rotor, the GSXR relies on an electromagnet to produce a magnetic field hence they are called the 'field coils' - which needs powering, this source is usually switched and in this case is the Orange.

-

May have appeared a daft answer to you but a blown bulb ain't never gonna work no matter how its wired!

-

It won't! Put a switch in line on the orange and tag it back to battery. Just remember to switch it off or it'll flatten the Bat.!

-

If memory serves me - the GS1000 has an almost 'hemi' combustion chamber and pistons to match? Getting the compression up whilst using the 4V pistons may be the issue rather than piston clearance and 4V pockets.

-

Not quite correct the GSX1100 (ET / Katana's - USA GS1100) use a 18mm pin like the GS1000 - the later GSX1100 (ie GS1150 / EFE ) had the 20mm pins, so those pistons could be fine. Just ask the seller the pin diameter?

-

Well that's a 'how long is a piece of string' question!..............5psi?.............10psi...............15psi ...........more? 1157cc, 1216cc or bigger? Compression / timing / loads of other stuff! All will have an affect! If its stockish / low boost you could get away with 5 points more than stock as a good starting point.

-

I know Blandits are asthmatic but some jets and a can can't bring the performance to GSXR levels - Bandit 100hp + 20hp = 120hp where GSXR = 125hp? (better exhaust, cams and compression) Dyno charts can be 'fooled' if you are trying to sell something........ and it isn't difficult!

-

Can't remember them having left hand threads? - That's why the lock washer is there! My old GSX happily undid itself years back - nut facked off and it was a long push back home!

-

I'm with you on this - generally fluid pressure on a seal should be to cavity side to push the seal lip into the bore to force a seal - done the other way the fluid just 'washes' past the lip. Harder to get into the bore but that's the point - lots of lube (oooh er misses!) and i'll go in.

-

Hmmm! Cam should be dripping with oil or at least wet if it hasn't run for a few days - what do the cam lobes / tappet pads look like? If scored then remove the cam - I suspect the cam journals may be toast! It may also indicate a gallery blockage up to the head on that side ....... more investigation!

-

Very nice torque curve and linear power - should be a hoot!

-

Or simple plastic cable tie - will eventually melt and fall off.

-

Possibly jumped a tooth or three and valves touching pistons? Check valve timing urgently - it won't get better, only worse! If it isn't, then at least you've checked and can be crossed of list - and it's an easy check!

-

Unfortunately stating the obvious - that's the problem when you drill out the key recess - either can't tighten sufficiently or can't ever loosen! You could try using a cold chisel or a punch near the outer radius and knock it round? I change that std bolt for a proper adaptor that has a hex on it, it stays in the case and a 'normal' pipe / hose fitting attaches to it.

-

The same number is quoted for the two companies and so is the likely to be the UK importer, and whilst they may offer tech support, I maybe wouldn't trust their advice - player of many instruments but virtuoso of none!

-

An in-tank pump isn't essential - maybe neater but more aggro. I use / used external Bosch types - just a bit more hose required.

-

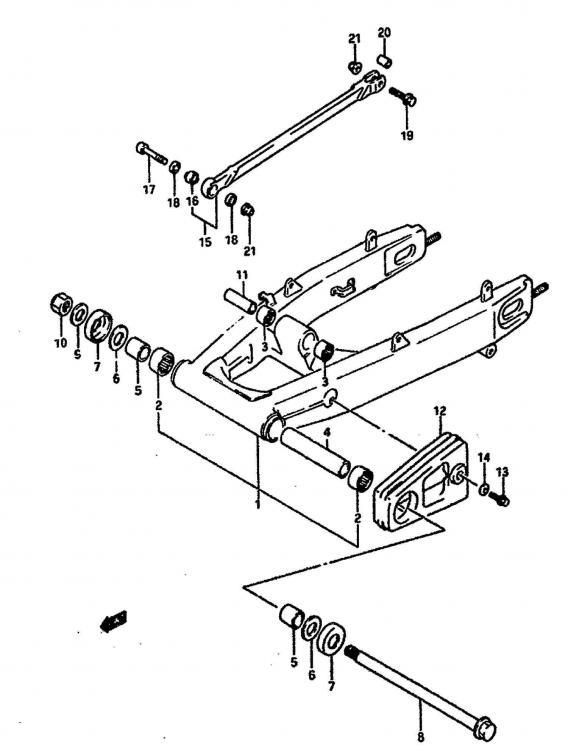

I didn't think an 18T was possible with a 530 chain - all to tight everywhere...... a 17T is tight enough! Chain always hit the swinger - it's designed to do that - that what the rubber guide was for - piccy is example - #12 Lot of people use a strip of nylon in lieu of the rubber - use domed or countersunk screws or the chain will catch and that's a world of pain!

-

What is the actual psi readings? With a DOT head i'm guessing should be 200+psi? Was the oil level static - engine off or engine running? Straight breather connection or 90 deg.? Sounds a lot more than is usual from clutch throw off !

-

Not really as the float valve would see 5psi instead of 2psi - wouldn't stop flow so instant flooding. The pitot's shouldn't give any actual increase in pressure but if they were positioned say, on a section where the pipe flared out / increased dia. the pressure would increase fractionally. I'd say they are best positioned near the compressor to get the 'earliest' signal with most direct hose run of 6-8mm bore to maintain gas speed. Maybe this is why pipot installs show such wide variations in function and efficiencies?