-

Posts

5,755 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Fast road/track 1200cc+ oil boiler . What to start with

Gixer1460 replied to dupersunc's topic in Oil Cooled

Agreed, M head is a good 'un but this was using 36mm CV's - a nicer carb to work with. The exhaust was built 'to the bike' and did have longer primaries than usual - maybe a 1/3rd longer - and I think that was what was responsible for the torque! I should have tried it on my 1460 - that would have been a hoot! -

Don't agree with pooling in the up pipe! That is the hottest point (around the collector) and any oil would be burnt off and the thing would be smoking like a Steam Engine! I'd say, looking at the clean oil, its turbo seal related - either fubar'd or badly fitted? You said you are using a dash 10 drain - is it horizontal anywhere or vertical drop throughout? Its possibly backing up in the pipe and overwhelming the seal?

-

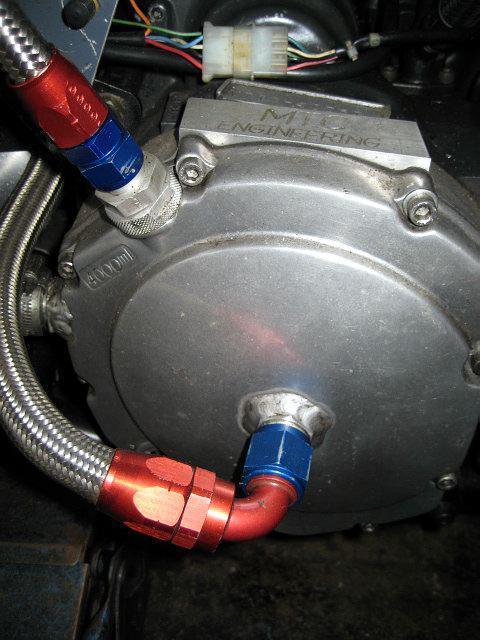

Re the Weld-on Q - the red cap in the 3rd piccy was the dash 12 turbo oil drain line return - not into case but into clutch cover

-

The longer screw has likely punched through the casing into an oil way or drain hence the leak, so welding is the ultimate fix. I've used JB Weld on heads before without drama.......this isn't directly exposed to 900 deg exhaust temp, probably nearer 200 - 250 so should hold ok for a fair while providing the area is well de-greased / oil free!

-

Whats wrong with the 'GSX Laser' drawings below? Click on them and they open fine for me?

-

Big bores and forced induction motors will all suffer ring blow by and crankcase compression - fact. Without increased breathing, you'll end up with blown seals and leaky gaskets - fact. Any added is a good option - my 1186 turbo had oil filler vent in dash 8, clutch cover vent in dash 10, std cam cover vent in dash 8 and additional cam cover weld on in dash 10 - excessive? maybe, but never blew a seal / gasket ever.

-

Totally agree Clive. I've no axe to grind or bury but i've known Sean for close to 15+ years and yes he can be a 1st class knob at times and we've had many, many discussions on ways of doing things - some things work, some don't (I had a Motec on my bike before he'd even see one, and dismissed mine as overkill!) but apart from trying to sell snow to the eskimos and sand to the arabs, he has made a name for well built turbo kits, primarily for late model sportbikes that will do what he says they will do, no doubts. They won't be cheap but HP never is and his come with guarantees - how rare is that. For those that don't know there are 3 or 4 testing regimes for Dynos - uncorrected, SAE, DIN and the 'other one'. All will give a different number, even the dyno type affects the number - it could be electrically or water braked, light or heavy drum un-braked, acceleration type, they all give different numbers. So, yes be cautious of unproven numbers, but when they come from someone who really does 'what it says on the tin' don't be so dismissive. Results speak and there are some American teams racing with BigCC turbo kits and they ain't complaining of 'lack' of HP! Its actually nice to be able to say that the UK can build and export to the USA, a niche' product in a niche' marketplace and be well regarded!

-

Advantage is increase in oil pressure, reduction of oil temp by not passing oil through the hot block and avoidance of the notoriously leaky block / cases joint. Easy enough to do - tap hole M6 and add grub screws - job done.

-

hard nosed rivet on new chain, how too flare , gsx1100f

Gixer1460 replied to brian darrien's topic in Oil Cooled

A sharp hardened centre punch should be enough to flare out the pin sufficiently - deffo a 4 handed operation though. -

For a stock bike with stock ignition, why not use Webmoto replacements - usually about £35 a piece as opposed to Dynas at £100 a pair with no advantage?

-

I had Barnett plates in my 1100K - was overbored and ran nitrous and the clutch was mint, upgraded to turbo and it went super grabby - not nice. Swapped back to std fibres and all good again - oh ...... was using a lock-up with both.

-

Most carb float needles won't withstand much above 2.5 - 3.0psi fuel pressure (usually lower) before leaking - remember most are only designed for gravity flow ie. virtually zero psi (relative to atmospheric). A compression tester is a start - a std say what now!? is about 160 - 200psi with no cylinder more than 10% drift against the others. This will indicate general cylinder state but there could be valve leakage and / or ring leakage - only definitive test is a leak down - not many workshops will have these but they are pretty foolproof as they'll show what is leaking, by how much and in each cylinder.....irrespective of any compression ratio

-

BEST!!! bit of advice written here in a while!

-

I hope you meant to type 0.2 bar or about 2.5 - 3.0psi? Obviously a boost sensitive regulator is a requirement to add boost pressure to that setting. Certainly the FCR's are an unusual choice but they are about as good as possible using roller slides to prevent boost induced slide jamming. Smoking could have a few causes not necessarily turbo - fubar'd rings / bores through over fuelling is a possibility?

-

Looks ghetto - looks double hard - looks good!

-

Well someone has spent a shedload of money on it - frame mods, Miki TMR's, dripping in Yoshi stuff! Neat engineering but Kats just don't float my canoe and 'fake' ones even less! LOL

-

Really? What you you think? Std gasket is sized for a 78mm bore and you're making it 81mm - how much is hanging into the cylinder getting burnt to a crisp! There doing something on a budget and there just being cheap! Sorry if it sounds harsh - learn some basic principles before you grenade your motor!

-

Don't believe everything your told.............................http://www.smbaker.com/sand-rail/manx/rebuild-ihi-rhb5-and-add-carbon-seal

-

I guess it was conceived when those daft fat 300 section rear tyres were in vogue! Can't see the 6" offset front sprocket working though! Not to my taste but each to their own!

-

Do it sooner than later or it'll cost you in burnt plates and warped steels. And uprated / excellent brakes are deffo not an option, neither is crankcase ventilation - you'll need more!

-

They will be f**kin hens teeth in a breakers - doubt any cars in the last 20 years have been fitted with draw through systems but usually the older Garrett 'T' series turbos can be retro fitted with carbon seals - T2, T3, T4. Likewise older IHI but not sure about Mitsubishi units!

-

Hmmm its a tricky one but not impossible. Hardest bit is avoiding blocking that oil? drilling at the bottom! I think i'd turn up a stainless, loose fitting plug to fit the smooth section to provide backing to build up the outer weld. You may have to grind out the threaded section and built it back with weld then face, drill and re-tap the treads?

-

All depends on what you are trying to find - combustion chamber volume to work out compression or pure in-head chamber volume to work out gas flowing effects on CR. The former is generally acknowledged as 26cc so I bet you'll find the piston domes will measure out at about 2cc which of course gets deducted from the head volume

-

Best/easiest way to remove paint from engine block?

Gixer1460 replied to Lloyd Hewer's topic in Oil Cooled

Its bastard stuff to remove which is usually a good thing! - chemical dipping probably the best way + it'll clean out a lot of the oil galleries especially if 'hot tanked' at an engine builders afterwards! -

Probably not much as the Oil Boilers are a tad bigger - more manly shall we say and real men only like manly things ! LOL !