-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Maybe a frayed cable - the broken strands catch on opening but don't on closing ? Also a badly routed cable could cause issues?

-

There is usually one carb that is fixed ie. can't be adjusted so wind the throttle stop screw to open the throttle blades until something like a 3mm drill just fits in the gap of that carb, then adjust all the others to match that gap using the same drill. This is a static balance - final balance should be done with vacuum gauges and running engine. Obviously once static balance done the throttle stop screw should be wound out or it'll rev its tits off on start-up LOL! As regards the choke - I don't know as i've never had a problem with the choke system!

-

Whilst a points set-up may sound 'minimalist' it can present more aggro than its worth! Wasn't the 850 fitted with solid state electronic trigger and ignition from the factory? If so, and you want to get rid of extra boxes, i'd fit a Dyna 'S' system - all fits behind the ign. cover and 4 wires to coils and that's it! You'll still need the ATU for advance but they are tried and tested on 'older' GS & GSX type engines.

-

Oh dear - but if it makes you feel any better - I have seen worse, like LOTS worse LOL!

-

As you say the rotor should be fixed via the taper and secured by that big nut! The starter clutch seems to be doing what it should but obviously it's not attached to the rotor. I guess its remove the rotor time and see what lies beyond!

-

Who knows? Maybe to justify adding a £100 / $200 to the bike cost for addition of £10 / $20 part (cost to manufacturer not spares cost!) There is plenty of crap added to bikes that don't necessarily need to be there!

-

What? If the tank is above the carbs the only pressure you are dealing with is atmospheric which will be virtually equal measured at the surface of the fuel in the tank and at the fuel level in the float bowls. Pumps are only required when the float bowls of a carb will be above fuel level in the tank or gravity flow is marginal ie. levels are nearly equal ! The carbs in my daily have a pump as they sit within the tank shell and for half the capacity of the tank the level is below the float bowls!

-

It may be wrong compared to original design but no one uses raked out front ends with 19" dia wheels anymore! My Kawazuki lost about 5 degrees of rake when original forks replaced with GSXR 1100L front end & wheel - and it certainly improved it. So wrong can be right in certain cases!

-

Your oil temp sounds way to high for 'moderate' use. Check cooler for blocked fins and if it's not an OEM one then its possibly too small / undersized!

-

Yes - and if that is the sound you are hearing expect to find the starter clutch with 3No. sheared bolts or the starter pawls out of position - & likely with springs missing!

-

I'm sure behind most 'engineering mistakes' lies a distraction that occurred! It is hard doing what is apparently a 'mundane' task, your mind races forward to something more interesting and things get missed - i've twice missed folding the tabs on final drive sprockets and yes they both came undone ! ! ! Task lists and tick boxes look nurdy but they do work, and btw - age may bring wisdom but it doesn't improve memory !

- 12 replies

-

- 1

-

-

- shiftingissue

- 1135

-

(and 2 more)

Tagged with:

-

Turbo's are driven by heat end of! A richer mixture will generally cool things down by not completely burning in the cylinder it also delays the onset of detonation also a factor in overheating an engine. But the rich mixture could be igniting in the turbine housing giving large volumes of gas instantly and spooling the turbine. Be wary of this occurring for too long - it is the method used in 'anti-lag' systems and if used too long or excessively it eats turbine blades / destroys turbo's ! If the system is fuelled correctly, an AFR of 12:1 WOT (IMO) is healthy . . . . . numbers below 11 and 10:1 are not and are masking excessive static CR or excessive boost.

-

You won't make many friends hitting them with attitude! You actually said the loom had six connectors - that doesn't imply no wiring fitted!

-

Whatever clearance you think you have, it 'looks' like the valves have touched! If it hasn't been started, you may have some bent valves. Freehand Dremelling valve cutouts isn't the best way, a milling machine and fly cutter is recommended just for accuracy and equal cuts.

-

Fork rechroming used to be relatively common when forks were RWU - harder to do with USD types due to disassembly required to permit grinding to size. Also chroming places not so common due to the PC / environmental bollux. It may be lots cheaper to buy better set of forks !

-

Well according to the manual - that CDI doesn't belong to that bike! GSX400E CDI has 6 pins (like a lot of Suzuki CDI's) and is case earthed / grounded.

-

What's going on with those valve cut-outs?

-

To increase sealing pressure - high CR's, Nitrous loads, and/or Boost pressure will usually blow a non 'o' ringed gasket.

-

Strangest MLS gasket i've seen - normally coated with something and layers riveted / tied together.

-

The gasket on the right is either a 'weirdly' coloured copper gasket in which case it'll need the barrels machining for wire rings or its a base / barrel spacer? The top right larger hole (stud hole) looks like it should take a locator ferrule?

-

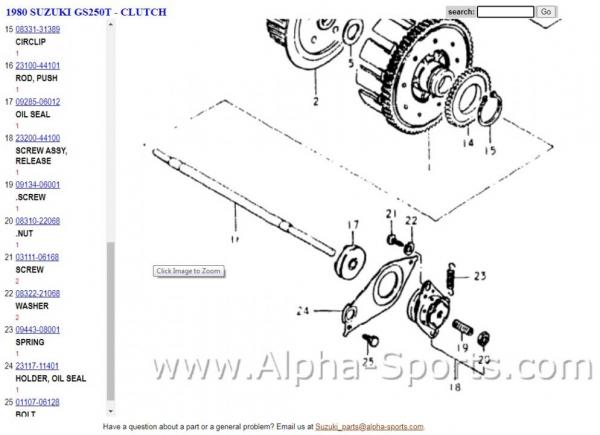

If this is the same bike ? ? ? Then it looks like a simple oil seal but also you seem to be maybe missing the retainer plate hence why excess oil forced it out?

-

If you can find a decent parts fiche ( the ones on Alpha Sports are bad for this) - each stud is identified length and position. Just to muddy the waters - when changing to HD studs - they are one length, all 176mm ! Makes things considerably easier !

-

Sounds like you need a tap repair kit as well as smokey and petrol smell may indicate fuel in the oil / crankcase - have a sniff in the filler hole?

-

Clutch GSX 1100 F doesn't disengage when warm

Gixer1460 replied to JannPedersen's topic in Oil Cooled

Being a pedant ! ! ! Only the outer is a basket - the inner piece is a hub ! LOL! Sounds like you have one of those wanky Blandit type baskets - Ali with steel band, wear prone and weaker if subjected to significant power increase.