-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

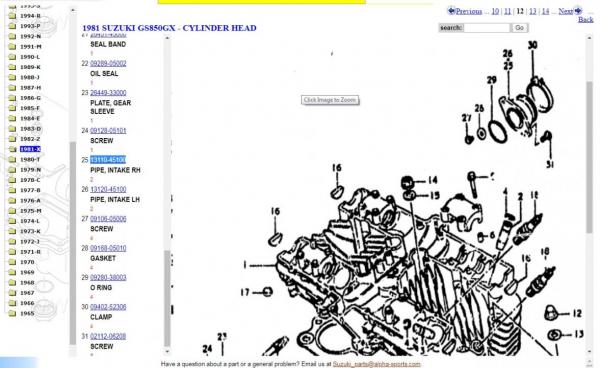

I did a search on the Alphasports site and i've got a problem! Early GS750's had slide carbs and a monoblock attachment to the head not individual rubbers! Later 750's had individual rubbers and CV carbs but the rubbers were slip joints held with hose clamps! Then I looked at the GS850 fiche - CV carbs and individual bolt on rubbers - two types a LH side pair and a RH side pair - part numbers 13110-45100 for RHS and 13120-45100 for LHS ! ! ! I wonder if someone has put an 850 head on the 750 bottom end? See here . . . . parts #25 & #26 I think the inlets should all have o rings so you may potentially have the wrong rubbers and maybe the wrong carbs ? ? ?

-

Pretty good ballpark though! I've done a couple of GSXR's and a mate did a 1st gen Bandit - all worked out of the box, following the instructions and got dyno'd just to check they were right - my 1186 was within 2 points of correct on the mains, nothing else needed changing! You could spend hours faffing around on a dyno only using std jets and needles etc IMO!

-

The numbers on the rubbers should largely be the same with the last few increasing from left to right (usually) like CO10, CO20, CO30 and CO40. Look on the Alphasports website and check what the part numbers should be - https://alpha-sports.com/suzuki_parts.htm

-

Accuracy is likely wrong - GS1000 - 19" wheel, GSXR 17" wheel - approx 20% speedo error!

-

Draw through carb and carbon seal ponderings

Gixer1460 replied to Samikoo's topic in Forced Induction

They were the circa 300hp turbo go to back end of the 90's and early 00's - mainly blow through on Busa's. I'd say 250 - 280hp realistically in a GSXR installation? -

Draw through carb and carbon seal ponderings

Gixer1460 replied to Samikoo's topic in Forced Induction

Where are you? UK, USA or somewhere else? If the former why buy from the States when there are plenty of turbo suppliers here - Turbo Dynamics in Christchurch, Dorset have helped me out plenty of times in the past. -

Re filter - I wouldn't unless you can be sure the tank is uncontaminated - shit in the fuel line / carbs is No.1 question / fault on OSS! And if the filter is new it will flow plenty unless its sized for a lawn mower - you want it running first, not breaking land speed records!

-

Doesn't help you now but i've never found one of these screws able to resist the use of a fat crosshead bit in an impact driver and using a BIG club hammer! Copperslip the threads on replacement - threadlocker is really overkill for these!

-

Don't see too many Million mile odometers Mechanical counters just keep counting as your pictures - the digital ones will probably be pegged so either replacement or get it 'clocked' by a mileage 'resetting' company.

-

Why? If the vacuum pipe is blocked the fuel tap won't work ! ! ! There should be : 1. Main fuel pipe about 8mm ID from fuel tap to carb fuel rail. 2. Vacuum pipe from carb 2 (in your case) to fuel tap about 4mm ID. 3. 2x Float bowl vents, each from between 1&2 and 3&4 carbs about 12mm ID - about 150 - 300mm long, left open and routed down towards back of engine cases usually.

-

ie. only one vacuum source to the fuel tap.

-

Draw through carb and carbon seal ponderings

Gixer1460 replied to Samikoo's topic in Forced Induction

1.5" or 38mm OD is what I used on mine and it worked OK! This kit was used on my 1186 Kawazuki - the picture was a trial fit on my drag motor that I was thinking about using with methanol - it was high comp hence the alcohol LOL! -

I think the hose 'C' in your picture is a Float bowl vent - if so they shouldn't be joined - doing so won't allow air in and fuel won't flow. Try disconnecting it and leaving both ends open for a start and see what happens?

-

Please stop grinding away on the starter - if it doesn't start after 5 seconds of using the starter, adjust something or look for something wrong - you'll just kill the battery or the starter or the starter clutch or all 3! And filling the throats with 'easy start' isn't getting it running - all you've shown is that it runs on highly volatile vapour!

-

Interesting! SS is a poor transmitter of heat but would have also expected higher than that . . . . . . . obs. not making enough boost!

-

Someone's on drugs with their pricing structure! £46 each or £130 / pair in chrome or another £25 for some black paint - Crazy!

-

Loooooooong Term Project............and it hurts

Gixer1460 replied to Hollomanje's topic in Air Cooled

Multi coloured spaghetti - perfect lockdown boredom killer! -

FFS ! If you tested the compression (cold admittedly) and got figures sub 4 bar i'm not surprised it doesn't run and sub 1 bar its unlikely to ever run! If you did not realise you have greater problems than 'it doesn't run' you should look for another hobby!

-

I dunno - I looked on the Morespeed website and they describe 5" Bates as 5 3/4" ! ! ! but the picture above would seem to indicate that dimension is across the body. Flat or shallow faced 5 3/4" sized lenses will be easier to find and may be a bit cheaper - Bates seem to be around £50 each.

-

Sorry I thought you were looking to get 'Bates' shell / bodies? I've just measured my 5" Genuine Bates lenses and some 5 3/4" lenses in my car are there is a difference in diameters so if a GSXR lense fits a Bates shell it may be 'loose as a cock in a sock' with a 5 3/4" sized shell ? Worst case - just buy 5 3/4" lights and shells and no worries?

-

Link pls - i'd like to see what's is available as I wasn't aware of anything?

-

Could go for a matt / flat black anodised finish if following the 'black box' theory - probably worth 2/10ths of FA difference LOL!

-

Good on the 'hot' side ie. turbine and exhaust manifold to keep heat in - not so good for rejecting or emitting heat away.

-

Science behind the madness ! - https://en.wikipedia.org/wiki/Black_body

-

It's clearly not a 4" light - and the 4" ones I bought only took 35/35w lights, which are ok on HD's! The 5" ones do take a H4 Halogen lamp. Not sure that other lenses fit Bates bodies (which i've never seen for sale without the lense/lamp)