-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

That works for splined lever to shaft but I think the question is more about sloppy shaft fit through casings and intermediate pivots and levers that don't clamp!

-

Those dogs deffo need an undercut - not surprised it's jumping out of 2nd as it gets mucho abuse!

-

A later one - M or N, if its got a diaphragm spring clutch. I thought the aluminium backplate was retained by the big 50mm sleeve nut? Could be wrong though as only took a std M clutch apart to fit a proper spring clutch and lock-up LOL!

-

All together now . . . . . . Oh no its not ! ! ! LOL!

-

No - lock up is just the 4 bolts that compress the clutch springs then it falls off!

-

Std. torque can be used if the engine is essentially stock, although if higher cylinder pressures are envisioned then higher torque is easy to add - will go 60 - 70 ftlbs but pulling case threads could be an issue.

-

Or bore out to take a bush like . . . . https://www.thebearingcompany.co.uk/category/quality-bearing-for-sale/oilite-bearing-bush/metric-plain-bush-bearing/ A google search for 'bronze bushes' should find a few suppliers?

-

Can't answer directly but the items you've got 'appear' to be correct but this image of the studs seems to indicate most all at one length with two slightly shorter and two even shorter - maybe 6-8mm max difference between longest to shortest, certainly no single odd one!

-

You said what I was thinking as I can't work out what is going where!

-

Blandit 1200 in Unitrak frame, to turbo or flat slides?

Gixer1460 replied to Motovalet's topic in Oil Cooled

A stockish B12 will always be hamstrung by its compression so to remedy that it's big bore time which will get the forged pistons to suit either NA or turbo routes. If you want circa 150hp NA some headwork &/or cams will be needed. Obvs turbo is sky's the limit. -

Indeed - more pictures required!

-

I have to admit mine caused issues after its build but was due to a low battery so the starter kicked back and loosened the bolt, I knew it wasn't worn as it had less than 4k miles use. It was a bastard to cure, finally used some diamond / carborundum grit infused paste to lock the bolt to the starter without having to stand on the torque wrench LOL!

-

GSF /GSXR engine cases Big Block without dry-blocking possible 85mm pistons ?

Gixer1460 replied to FJD's topic in Oil Cooled

Ok, gotcha now! But knowing the angle doesn't really help, as, supposing its 10 deg, what are you using to a) measure that and then b) set the machine up at that angle? You are working against tolerances and inaccuracies which could stack up and end up +/- 0.25 degree which the gaskets won't take up? (probably worst case but you get the drift) Its easier to clamp the case using a sized bar through the bearing journals, then sweep a test indicator across the gasket surface to achieve flat and perpendicular to the boring bar & the table. You shouldn't adjust the machine to the part, adjust the part to the machine IMO. -

Fred's requirements are somewhat more 'extreme' compared to even a high spec engine - standard washers are more than adequate for majority of builds! If you can / are building enough boost / cylinder pressure that head lifting is an issue then i'd also be looking at upping the stud diameters as is common with Busa engines - std. 10mm waisted studs / bolts upto 12mm straight sided and even 13mm for extreme use, all HT 12.9 quality bolts and 120-130 ftlb torque

-

GSF /GSXR engine cases Big Block without dry-blocking possible 85mm pistons ?

Gixer1460 replied to FJD's topic in Oil Cooled

See my answer elsewhere to your other post. But confused re, last sentence? The cylinders / block should be bored perpendicular ie. 90 degrees to the crankshaft so why would anyone want to make that operation more difficult by having the gasket mating surface in a different plane. Reference surfaces of top of crankcase, bottom and top of block, underside and top of cylinder head are ALL usually parallel to crankshaft axis. I have seen on different engines, the underside of the cylinder head faced at an angle as a tuning mod to increase combustion / change valve angles / squish etc., but generally in most cases all are parallel. -

I can only speak for my engine that uses 85mm bored (ie 6mm over stock) liners in 'M' cases and doesn't have external oil lines. Mind you i've never had the bottom end apart since it was built so I don't know if the builder did something 'clever' in the oil jet area to compensate for the bores. Looking at the pictures above an additional 3mm boring would get the metal separation pretty thin IMO!

-

GSXR starter clutches are fairly reliable (when compared to those fitted on GSX AC bikes LOL) they either work or don't! The sprag rollers could be worn or the springs have lost tension which could be worst when hot as oil would be thinner? If the bolt had come undone, its really obvious and it wouldn't turn hot OR cold! I've never tried taking one apart and spare internals (if even available new back in the day, will be rare now) could be fitted, although whole unit replacement with a good used unit is generally cheaper option.

-

I'd personally disagree as it looks like the maker has attempted to get equal length pipe lengths, no particularly tight bends and pretty good flow direction into the collector! Obviously with raked out forks there is more space for bends and turbo placement - completely opposite to a road bike where manifold must be tight, compact and much harder to achieve equal length tubes (which isn't that important unless looking for max outputs IMO) And looking good and working is different to looking pretty - nothing wrong with looking pretty, but a hardcore racer won't be spending money on paint or bling if that money could be spent first on something that would make the bike faster/quicker.

-

Dragbikes don't have to look good - just go fast!

-

Could be done but probably the amount of 'cutting & shutting' required would mean a brand new one will be cheaper!

-

I don't know what year model the carbs are from so this is a guess but indicates both st1 and st3 ! https://dynojet.co.uk/amfinder?find=suzuki-gsx600-fj-fk-1988-236182&sid=vCdyH7kyd0 Just use the sites product search to locate correct kit. These kits are designed for a certain engine matched to certain carbs so can't just be applied to other combinations. The fact you are using 600 carbs on a 750 engine will bring its own tuning issues but a dyno is the place to resolve those! As said the exhaust should be close to what is finally planned but a st3 kit will work with most things from mild to wild!

-

Sometimes 'we can't see the wood for the trees!'

-

Fairly standard issue when the airbox delete mod is carried out - mid range flat spot. You can go to hundreds of garages but if they don't have a dyno, you are wasting time and money! Dynojet St3 kits are available for the GSX600 range and will likely address the mid range issue with a quick dyno session to check overall correct fueling. But please address the exhaust situation as ultra short, ultra noisy exhausts just piss everyone off and if extreme enough just make the engine run like shite!

-

My god I've been doing it wrong! Short thread into block with blue loctite finger tight - job done. Never pulled a thread or run out of thread length - weird!

-

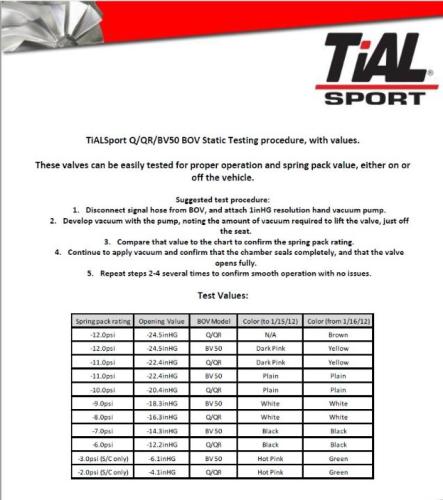

I would asume you have access to vacuum gauges to set up your carbs? These should have the resolution you need, then follow . . . . .