-

Posts

1,979 -

Joined

-

Last visited

Reputation

2,556 ExcellentAbout no class

- Birthday 01/20/1966

Personal Information

-

Location

Montreal , Canada

Recent Profile Visitors

2,454 profile views

-

hotrod satin black 2K

-

- 6 replies

-

- 15

-

-

-

thnx DnD

-

thnx Clive…. going to give it looksee

-

I seem to recall there is a difference in tooth count for the oil pump drivegear that fits on the rear of the basket to do tge conversion …. what is tge tooth count ?

-

…. source an 1127 or 1052….. pop it into your chasis and have some fun .

-

easy stuff first ! unplug the fuel hose from the petcock ( while in the ON position) if it leaks …. diaphram and spring kit . if the needles and seats are worn and leak …. it will gradually let fuel into the intake tract and into the motor . pop off the oil filler cap … put your nosey by the fill hole and get a good sniff …. if you smell petrol …. you have a problem .

-

plug wires on the proper plugs 1-4/2-3 ? how about the petcock ? diaphram good ? needle and seats ? float height ? how many plugs are wet ?

-

when you seat the screws before turning out to final adjustment ….be gentle as the tip can break off and become stuck in the orifice . I had to repair a set of rs36’s that the owner fucked up

-

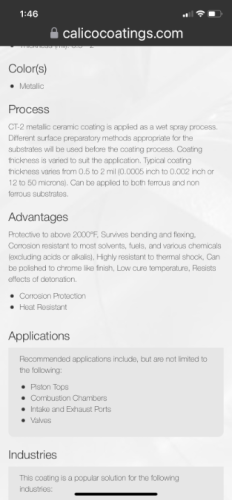

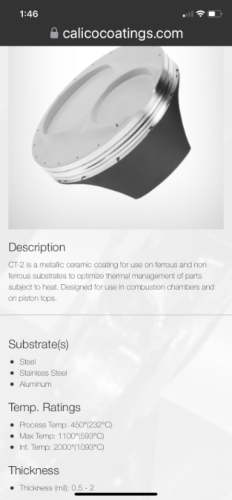

Calico CT2 ceramic coating for combustion chamber

no class replied to no class's topic in Forced Induction

lol….. took me 20 minutes to get my vision back ! -

Calico CT2 ceramic coating for combustion chamber

no class replied to no class's topic in Forced Induction

-

Calico CT2 ceramic coating for combustion chamber

no class replied to no class's topic in Forced Induction

-

Calico CT2 ceramic coating for combustion chamber

no class replied to no class's topic in Forced Induction

-

Calico CT2 ceramic coating for combustion chamber

no class replied to no class's topic in Forced Induction