-

Posts

5,755 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

My Brain hurts !

-

that explains a bit ! so if you used gsx pistons in a gsxr you should get a similar low CR?

-

MTC used to be the 'go to' in GSX draw through installs as advertised @ sub 8:1 CR - it's the same piston used in turbo GSXR's but with shorter stroke gives 10:1 CR! Wasn't going to say anything as you wanted lower!

-

Now I'm blushing !

-

You got it - Half the skill in drag racing is in the clutch tuning! Launching 500hp on a two step at WOT and not blowing the tyre away takes some clever shit!

-

Not exactly a budget build anyway! I wonder which bit is still / remains Suzuki produced ?

-

Slider clutch! Or twist and go for drag racing!

-

cos shaftie frames don't use 'normal' swing arms!

-

Electrics that old are going to try most peoples 'Grey Matter' ! When you said 'replaced the brushes' my immediate thought was Generator / Dynamo - surely not but looked up the parts fiche on Robinsons and its described as an alternator except its backwards to how we normally see them, in that the magnet spins via crankshaft whilst the field coils are stationary! The brushes are doing what - i'm not sure ! Do you have a workshop manual Suzuki or Haynes ? ? ? That should have a reasonable explanation and troubleshooting section. Its usually the regulator / rectifier that goes bad, either over charging or not charging at all. They are all solid state and un-repairable (by most people!) and usually have to be replaced with something else - usually from *onda or ^^hama as Suzuki charging electrics from that era suck big time! Some colour photos of rotor and plate assembly could provide info what bits to test and what to expect, as this is likely as much a mystery to us as it is you!

-

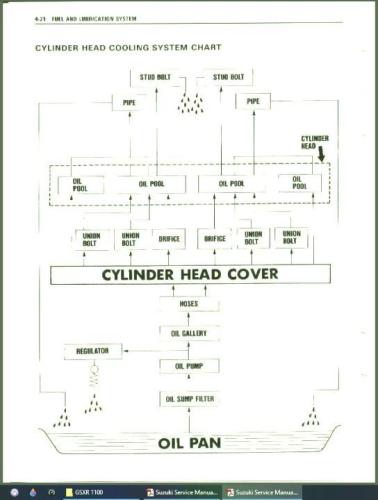

Yes, but the point is the filtered oil is delivered, at pressure, to the bearings whilst the un-filtered oil merely 'sloshes' around the head then drains back to the sump. I have no axe to grind, one way or the other and I do have my cooling circuit connected to the cam feed circuit without issues so far, but I've yet to see empirical evidence of cam bearing failure due - solely - to this combination, but I guess it is possible. Even if the bearing HP feed pressure was 'diluted down' to cooling circuit pressure (30+psi at a guess but with greater volume) that is still more than adequate to prevent metal 2 metal contact - Aircooled GSX's survive at considerably lower pressures for cosmic mileages! It is a good reason to keep on top of oil and filter changes though!

-

Unfortunately Clive, on this occasion he's right! See attached Cooling Oil Circuits diagram from the workshop manual. Cooling oil doesn't get filtered - bizarre I know but thats the way Suzuki designed it!

-

Aged battery? I'm guessing testing outside cylinder with 'down on power' battery also being pulled down with the starter motor? At least you are getting sparks - its when you don't, that real diagnosis starts!

-

Why ? Do you suspect a problem? Many thousands of bikes, road and track have used HD stud kits without under oiling the top ends. Don't forget, without the cam cover you'll get many litres of un-restrained cooling oil squirting every which way!

-

Yeah a 'rattle gun' will shift it - hold the hub with a gloved hand ! At a push, even an impact driver (the type you whack with a lump hammer) may do it!

-

Strangely . . . . if you buy that 'kit' RU - 2922 it costs £149.99. But if you buy RU - 2920 x2 it will only set you back £99.98 ! ! ! Its the same filter, just the first is two in the box and the latter is bought as singles! And yes the 60mm hole variants are the correct ones. https://www.knfilters.co.uk/ru-2922-universal-clamp-on-air-filter https://www.knfilters.co.uk/ru-2920-universal-clamp-on-air-filter

-

Just know that if you do use JB Weld and it doesn't work & you do have to get it welded, the job just became a whole lot harder, probably to the point of grinding the whole 'nub' off, back to clean metal and building it back up again, then drilling and tapping!

-

Interesting point ! I can't say I've seen any post or question here regarding use of DJ fitted carbs with a turbo. In practice, the DJ kit is fitted due to the loss of airbox & other airflow related modifications and they work well in this respect. I can't see any reason why they would not work as well when having forced air blown through them! Whilst standard settings / jetting can work - is it optimal ie. std. needles are shaped to deliver a leaner cruise mid range - just when a turbo is starting to make boost so not ideal. As most dyno tuning is only done at WOT, i'd guess no one knows exactly what is happening in the mid-range most of the time. Who's going to give it a go?

-

As said, welding not a problem if you get a GOOD welder - the hardest problem is getting the crack oil free, as heat from the weld will cause any oil to bubble out and contaminate the weld, might just have to give it a try!

-

According to Haynes that serial number comes back as a GSX1100 T - the only model starting with 1 - made between aug 79 & Oct 80 - Started at 100001. But is in the same production period as ET's and EX's but they started at 500001. Hope that helps.

-

Adding a Gear Indicator

Gixer1460 replied to TJS's topic in Water Cooled, V-Twins, Singles and 2-strokes

Got yer finger on the pulse of the thread Clive LOL! -

Easiest way is get an HPI check done on the chassis number - I had the same problem with SWMBO's trike, ie had chassis number and V5 had gone to DVLA and never came back, never been on road as a trike so came with no plate! HPI comes back with loads of info and most importantly, the original reg # when it was a bike!

-

Could be badly adjusted cable ? The usual test is decent road, bike in 4th or 5th gear at lowish speed but not lugging, apply a good amount of throttle. If bike speed seems to keep up with increasing revs - its not clutch! If revs increase lots more than apparent speed then clutch is slipping. May need plates but with older bikes (maybe with original clutch components) its a 'rabbit hole' and could entail plates fibre and steels, basket, hub, pressure plate and springs or any combination!

-

Just because something hasn't failed YET, doesn't mean it won't in the future. Better to 'over engineer' something now so that failure isn't an option later.

-

Probably - old Brit bikes used to have near vertical shocks on their short stubby arms, but shock & damping technology has moved on since then!

-

Sometimes its 'form over function' ie. they fit better that way ! In an ideal world the shock should be perpendicular to the arm through its travel for maximum stroke and damping effect but if you 'lay them down' then for a given spring pressure, they will feel softer and damping will be less - sometimes good, sometimes not!