-

Posts

188 -

Joined

-

Last visited

Reputation

331 ExcellentPersonal Information

-

Location

the netherlands

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I would say blow trough is the better solution, draw trough has some advantages but for the street it has too many disadvantages, driveability being the main one. draw trough con hot turbo under the tank: vapor lock exhaust close to your leg Longer exhaust pipes so more lag One large carb Hard to add an intercooler Turbo seals needs to be able to deal with the fuel Turbo needs to be able to deal with vacuum Fuel can be unevently divided between cylinders: 1&4 tend to be leaner, or difference between 1-2 & 3-4. Sometimes a divider is added to counter that (Iguess you could add 4 injectors in the plenum and have the carb replaced by a large throttle body) If the engine backfires you back is literary on fire because mixture is in the whole intake area (compressor housing, and plenum) Very violent on/off performance especially on large turbo big power bikes Difficult to add a muffler draw trough pro easier to set up the one carb, because there is no pressurisation of the carb and its very easily accessible No FPU needed No pressurized carb needed Gravity drain of the oil is easy Front wheel clearance is not a problem Very violent on/off performance especially on large turbo big power bikes looks really oldskool and cool and imo the only good reason to do it Blow trough con Setting up the carbs can be difficult (could be mitigated by adding injection but that also has its challenges) Carb sealing can be a challenge, fuel pressure is critically important to stay in that sweetspot between leaking and fuel starvation and so is float and needle/seat condition. (Again could be mitigated by adding injection but that also has its challenges) Front wheel clearance especially on larger turbo's. I bought header and turbo at proboost and that fits nicely. Still need to experience emergency braking front wheel clearance........ oil return need most of the time a pump. Can be electrical or mechanically. You could try gravity drain but if turbo sits low it can smoke like a mf Blow trough pro Off boost behaviour is much nicer, depending on CR it can be close to stock so suitable for the road Intercooler is possible No special seals for fuel and/or vacuum are needed Easy to add a full exhaust No issue with AFR being different per cylinder (unless fuel injection, then that could happen with poor plenum design) Even without intercooler intake air is cooler so more detonation resistant = more boost = more power

-

Many turbo's come with a boost reference connection on the compressor housing. I also take the boost from the compressor housing, it being the shortest way to the boost controller which in turn sits close to the wastegate. I have no overshoot or oscillation, and the advertised 6psi spring results in 6psi measured in the manifold. (of course check if its true for your wastegate) It seems to me that control is better in shorter lines and no large volume such as a plenum that can cause delays. Since many people use the plenum for connection to the wastegate with good results, I guess in real life it not a big problem. Another consideration when using the compressor connection: the hose is short and simple to route, so chance on it getting pinched somewhere under the fuel tank is much smaller. If the hose is off/closed the wastegate doesnt open, not fun.

-

Manual states and I quote: "DO NOT Mount the wastegate so that the actuator is less than 100mm from a heat source." I'm kinda new to this, isnt this normally close to a turbine housing and headers?

-

In and out at the end of the rail seems a better solution to me, so basically as your picture but at both ends.

-

If there is boost creap, be careful. Boost could get higher then intended. I assume you have an inernal wastegate with actuator. If you tighten that wastegate to get higher boost, it also cant open much resulting in boost creap. For higher boost, better use an actuator with stronger spring, or a boost controller.

-

Yeah dynamic compression is a result of many factors of which you stated some. So what is true for one unique setup doesn’t need to be for another, let alone different engines. That is why it’s so useful to get data from people with the same engine and a similar setup.

-

I don’t think the speed in which it spools up results in problems. Afaik detonation when turbocharged occurs around peak torque, or at prolonged high rpm when everything gets ff hot. Both have nothing to do with spooling up. I can imagine a poorly chosen turbo heats up air more which doesn’t help. efi and carbs both are fine as long as afr is correct. You can run into fuel starvation with carbs when you turn down the pressure too much to prevent flooding. Then again there are multiple ways to f up efi too :-)

-

According to this 15psi at 9:1 is not safe (18) and maximum cr for 15psi is 8:1. Sounds conservative but indeed it’s safe.

-

detonation due to overdoing it

-

Had 13.5:1 1277 wiseco’s, still thought it was too slow and went the turbo route. Didn’t want to buy new pistons so did machine them to approx 10:1 and thought this would be ok up to 10psi. I turned it up a bit more past 15psi and that did held up for a little while until all 4 pistons gave up during a flier. Ringlands broken and it smoked like a mf. Bottom end was fine, head not so much and of course barrels and pistons were gone. Detonation due to too much boost for this setup. Did fix it with new again modified wisecos and thicker spacer plate at 8.5:1 and drove that for years without problems with 15 psi. Past and now I run 98 octane pump fuel , stock plugs, no intercooler, stock cams at stock timing, 4 degrees ignition retard and a proper oil cooler. Before I had a td04-16t and now a td05h-16g It’s hard to compare setups, but I think that 15 psi on stock cr is pushing it.

-

On the dyno that probably will be ok. On flyers it’s not. Been there repaired that.

-

good info thanks!

-

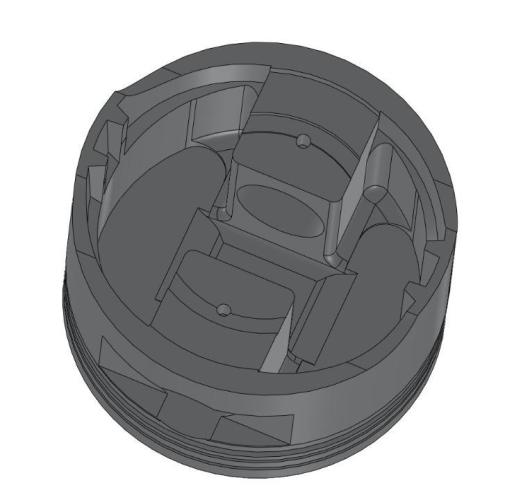

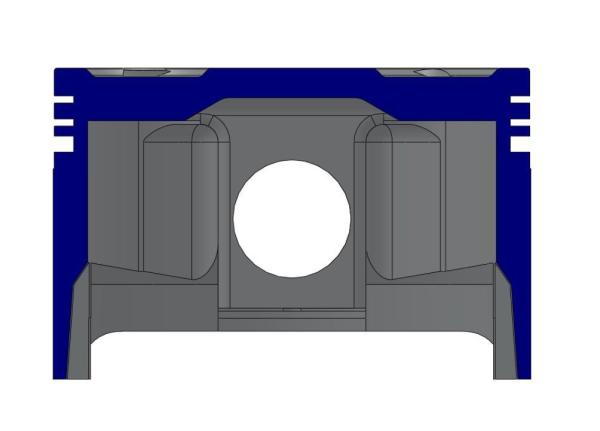

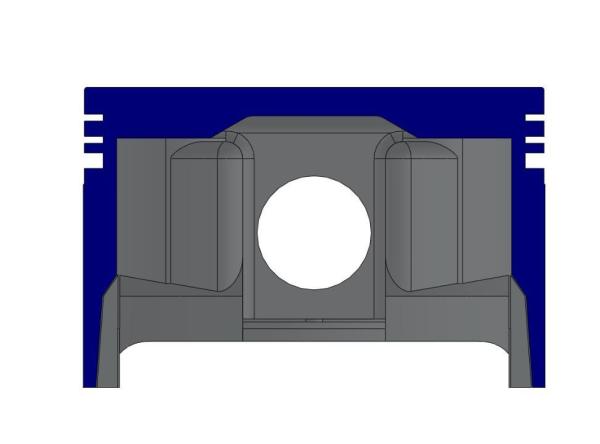

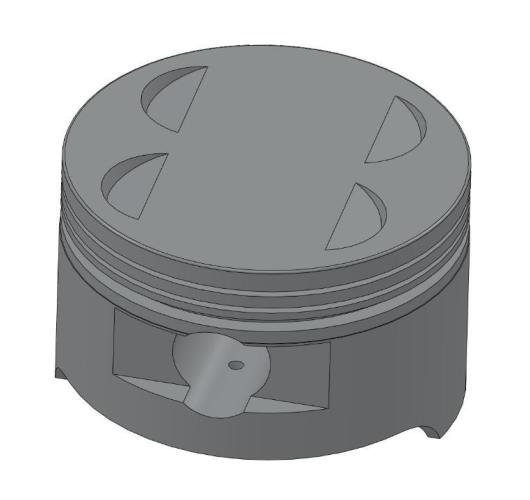

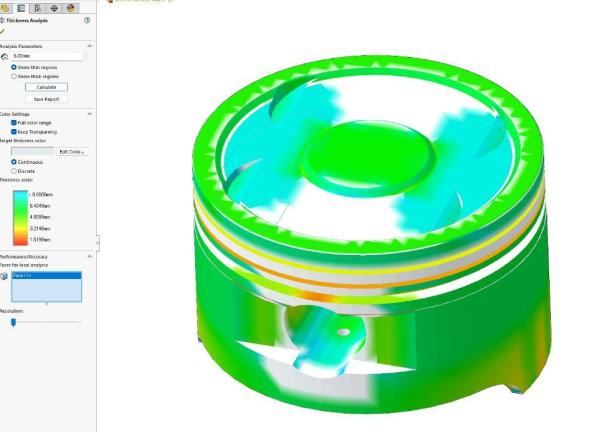

Got the MTC 81mm 10:1 pistons. They are much beefier around the wristpin area. They are now boring and honing the cylinder block. Before I mentiioned I want the CR to be 8:1 - 8.5:1. Reading a bit more in various places I think its a bit too low for a road bike. 9:1 should give faster spoolup and better low end while it should enable 15psi on 98 octane resulting in around 270hp. (input welcome) Played in CAD with the pistons to see what could be done to lower the CR while maintaining squish. Around 4cc should be cut from the piston to achieve 9:1. Thing is, in the middle of the piston is a relatively thin area of 5mm which I think I should leave alone. A bit surprised that turbo/nitrous pistons have a thin area in the middle. Maybe because they mainly make high compression pistons from this casting? The rest of the piston is 9mm so I could reduce that by milling out a ring 1.5mm deep. Of course I'm first going to verify deck height and actual compression volume before ruining new pistons Does that make sense, or does that f@ck up combustion in such way that it would be better to add a spacerplate and accept the larger squish? unmodified MTC 81mm Unmodified MTC 81mm Bottom of MTC piston Modified MTC Modified 81mm MTC Modified 81mm MTC thickness check

-

In my experience dynojet kits are not an instant improvement especially when intake/exhaust stuff is not stock. I would let your local dyno specialist jet it properly. No point in tuning a bike that needs maintenance so make sure carbs are in good order (needle/seats ok, fuel level ok, replaceworn out emulsion tubes, no air leaks anywhere) and at a minimum airfilters are clean. Best to do all the relevant maintenance as well : plugs, carb sync, valve clearances. A dynokit doesnt add anything at WOT over a properly tuned bike. It doesnt improve airflow into the combustion chamber so it cant improve performance. If it adds, it just means AFR was off before. It could improve throttle response because of the soft spring, drilled holes and needles to match. But that improvement when going trough the gears is exaggerated on a dyno because of the much faster increase in rpm then what happens on the road. If you want less loss with gear changes just fit a quickshifter.

-

my 5 cents: used castrol full synthetic 10W60 before on a gsxr bigbore. Fairly high sudden oilconsumption and slipping clutch. It wasnt strictly speaking motorcycle oil so there is that. I use castrol halfsynthetic RS 10W40 ever since without issues including gsxr1000, hayabusa,modern gsxr750, a high compression bigbore and a 340HP turbo. I change it every winter which for me means 2000km. (the turbo bike every 1000km or every year whichever comes first, including a good check on shiny debris:-) Any halfsynthetic 4stroke motorcycle oil from a proper brand would be fine I imagine, I'm just used to this stuff. Thing is with full synthetic, they can dissolve gunk which was building up inside your old knackered engine causing issues, especially higher oil comsumption. On a fine rebuild engine I would expect no problems except possibly clutch which can be circumvented. (of course dont use full synthetic to run in new pistons) Personally I would stay away from all kind of special so called high performance racing oils if they are not for 4stroke motorcycles and not for road use. Some of them degrade quickly since they are made for short high performance and not for longevity.