-

Posts

2,689 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Duckndive

-

Its still a work in progress last I heard

-

-

Well i've not visited Hamatsu i have visited Triumph at Hinckley and many car assembly lines ££££ for tooling and mechanical aids is mega Trumpit use a lifer on the engine mounts to position the engine in frame that's almost effortless so given the little slight build of most Jap workers i would expect they use similar tactics and the removable frame rail helps the process "it may even be attached to the engine prior to fitting" Most of the newer buses and thous are simple drop frame over the motor builds so even simpler tooling wise Small side note a senior engineer responsible for training line workers at a major uk car plant told me the task has to be able to be learnt and be repeatable to the correct standard in 20 mins ............. Track speed is based on the slowest process on that build

-

I destroyed a 1260 hybrid at East Kirkby due to no filters so I use these on stacks on Micky Roonies now ...

-

its in the OEM manual

-

Its is what it is then TBH I think manufactures quoted C/Rs can be on the optimistic side at times

-

Have you took into account the compressed head gasket thickness as opposed to a new one...? Not a massive difference but it all matters

-

i think they look best and more in proportion when they are 3/4 or 7/8th scale ....

-

GS1200SS Parts Book/Fiche/Website/Manual??

Duckndive replied to ibrakeformoose's topic in Oil Cooled

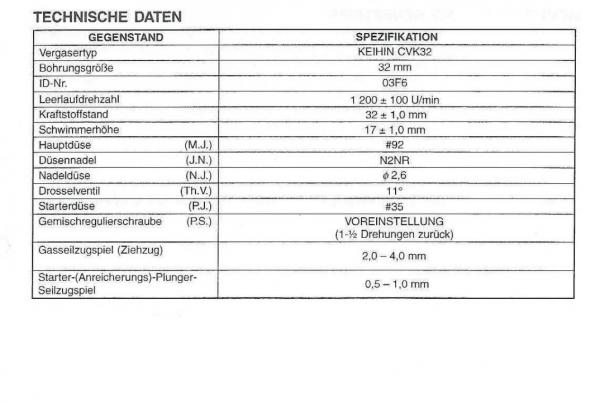

I guess the carbs are item no 183959080576 then -

GS1200SS Parts Book/Fiche/Website/Manual??

Duckndive replied to ibrakeformoose's topic in Oil Cooled

most likely same set up as 1200 Inazuma Carbs then on 750 carbs the needle height is fixed and has no clip so the only way is up... -

i,ve done it that way a few times i found that having the engine vertical "ish" with the studs over the edge of the bench worked well...."i did use buttons and not circlips to retain pins thou" the other way is to use ring clamps and fit the block to the pistons and rods... i always install New Rings Dry into a Dry Bore.....

-

GS1200SS Parts Book/Fiche/Website/Manual??

Duckndive replied to ibrakeformoose's topic in Oil Cooled

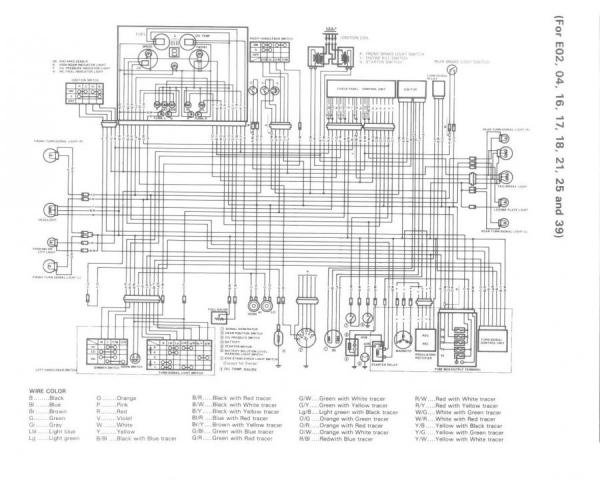

i got a genuine suzuki manual for my inazuma from Eblag and found a german PDF version on the net There's a lot of 1200ss stuff on Jap Sites if you use gooogle translate -

GS1200SS Parts Book/Fiche/Website/Manual??

Duckndive replied to ibrakeformoose's topic in Oil Cooled

Its basically a blandit with a body kit but Suzuki will do a bike specific manual at £££ -

GS1200SS Parts Book/Fiche/Website/Manual??

Duckndive replied to ibrakeformoose's topic in Oil Cooled

Parts book,s on Robinsons Suzuki and Fowler's amongst others Manual,s on carl slater https://www.carlsalter.com/suzuki-service-manuals.asp -

Dooooh must try harder

-

you don't say what engine ..but a look on the parts fiche for the bike may help as they will have different part no ..

-

I would have thought the returns that match the engine the sump you are using is from would be the ones to use as would be the oil pick up that goes with said sump

-

TBH you could buy a complete running EFE and break the motor and sell parts buy a oil boiler motor and fit it...and end up quids in I luv the air cooled motor and still have three but the oil boiler has so much more going for it from the get go... The EFE "engine" was only produced for a short time in relation to other air cooled models which with the many that died on drag strips and breakers adds to the scarcity of the engine " unrelated but " Suzuki even killed sales in the final year of EFE with the introduction of the Slabie

-

The 1216 Oil Boiler motor in my Turbo EFE cost less to buy and build than just the crank-work on my last air cooled turbo EFE...

-

I,ve always used John at Revs Racing https://www.revsracing.co.uk/road.htm Have you asked the Kid his misses works at a suspension place

-

Project Thread here

-

Yeap it has to be dispensed for you ...which if you are a tourist is so much easier than the self service credit card pumps in other states that wont accept your non US registered card....

-

-

Someone on the original site had an efe with kat bodywork...

-