Arttu

Members-

Posts

907 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Arttu

-

Hey, everyone must start from somewhere There are some photos and info about my first EFI conversion on stock GSX engine, almost 15 years back: www.iki.fi/arttuh/mopo/en_summary.html I'm not sure about carb spacing of your GS1000G, maybe it's the same than on GSX1100? In that case there aren't much choice for "drop-in" throttle bodies. Old Kwak GPZ is the only one with correct spacing, AFAIK. But with little modification you can make others fit. I wouldn't try to use any stock ECU from some modern bike. Too much trouble to arrange all the sensors etc. like the ECU expects and then tuning possibilities will be too limited to make it work properly on completely different engine. Better to use some fully adjustable aftermarket ECU. Microsquirt is one suitable option. Or I can also arrange something if you are interested

-

So this will be bored to 75mm? I have a damaged cylinder block where I could take one liner for you. I just don't remember if it is 74mm or 75mm already. I can check if you like.

-

Probably doable but not feasible. Sure you can install all that and most likely also make it work (sort of) with enough effort. But the problem is that remapping / tuning tools for these systems are too limited to make this level changes. At least if we are talking about stuff that is available for normal people. If you have access to full development environment from Bosch / Nippon Denso / whatever situation might be different. So due to this you probably end up adapting the bike to the control system and not other way around like it should be. And most likely the result will be less perfect. That's the reason why I would recommend using some aftermarket system that is designed to be adjustable.

-

I think @bruteforcehad K04 on his bike at some point. And possibly @Leblowskiwas using K03 on 750 years ago if I recall correctly. On general level it's good to keep in mind that there are dozens of different variants on both turbo families and their specs can vary a lot. But if we are talking about the turbos that were used on 20 valve 1.8T VAG engines then situation is slightly simpler. For K03 there are two main variants, "basic" and "sport". Can't remember exact numbers. They were used on 150hp and 180hp engines. Basic is good up to 180hp and sport maybe 200hp. IMO both are too small for 1100 engines except maybe for some low power/budget experiments. But even in that case consider carefully if it's worth of effort. K04 turbos were used mainly on 210-230hp engine variants. The model numbers are K04-22 and K04-23 if I recall correctly. Both are capable for maybe 250-270hp. These should be ok for basic 1100 build. In addition there are also some smaller variants that are intended as bolt-on upgrade for K03 turbos. Model numbers are something like K04-11 and K04-15 (maybe). They are capable for slightly over 200hp. As far as I know all models are prone to cracks on exhaust housing. So be careful if you are buying used one.

-

Many aftermarket engine management systems can do some kind traction control. Typical solution is to read both wheel speeds and then reduce power if there is too much difference. The same concept works also as wheelie control as front wheel speed starts fall behind rear if it's in the air. So if you do EFI conversion with some system that is capable enough you can probably get quite far without too much trouble. However, more sophisticated result you want more efforts are needed. And there are several limitations with this basic concept. One problem is power control. On typical aftermarket EFI setup this works by controlling ignition timing and boost (if applicable). But there are limitations what you can do with these. Boost control is somewhat slow to react even in the best case. And with NA engine this obviously doesn't help at all. Ignition control can react quickly response on power output can be quite non-linear on some engines. So as result power control may not be as smooth and accurate as you would ultimately hope. Modern factory bikes rely heavily on drive-by-wire electronic throttle control as it allows precise and quick power adjustment. Naturally it's possible to fit such system also on old bikes but it adds another degree of complexity to the project. Second problem is detecting all possible problem cases early enough. Wheel speed comparison method should detect wheel slip and most likely also wheelies nicely when you are on move and going relatively straight. But when talking about quick jump ups from standstill or subtle wheel slip while leaning at maximum angle things get more complicated. For those you may need additional sensors like gyroscopes, accelerometers and suspension travel sensors. And first of all, more complex control algorithms. And even if you get all this installed on your bike it will be probably pretty significant effort to get everything tuned to work on this particular bike. And by significant I mean something that may take months for professional engineering team. I have to admit that I haven't played much with traction control by my self. So I can't speak from first hand experience. But if I were you I would do this piece by piece. So starting with something that is most likely doable with reasonable effort and not worrying too much about the ultimate solution. In practice, start with EFI conversion by using some ECU that can do this basic traction control. Get it working, play with parameters, see how that works in real life and how far you can get with it. Should keep you busy next few years Then when you have found limits of that concept you can decide if you need something more. At that point you will have much better idea what you really need. If you try to do everything at first go changes are that you won't ever get anything running on road...

-

Lockup clutch but still slipping, tips & tricks?

Arttu replied to bruteforce's topic in Forced Induction

Sounds like you have at least enough pressure on pack if you can't pull in the clutch at high rpm. So I wouldn't add weights or spring load before checking everything else: -Is the air gap correct, can the levers press the pack all the time? (Not bottoming out on something) -Are the steel plates straight and flat? And if they are glazed glass bead blasting can help a lot. -Clutch hub and basket smooth and straight? -Operating mechanism not limiting compression? -

General rule of thumb for wire sizes is 1mm2 / 10A. So 1mm2 wire is good up to 10A continuous load and so on. From electrical standpoint there there isn't any problem if you use too heavy wire for actual load but it will make wire bundles thick and stiff pretty quickly. So it's a good idea to use some sense with wire selection. If thinking about typical OSS bike I would use roughly following sizing: +12V and GND from charging regulator, main feed from battery to fuses: 2.5 - 4 mm2 headlight, ignition coils, generator wires to regulator: 1 - 1.5 mm2 turn signals, tail light, other misc stuff: 0.5 - 0.75 mm2

-

Benefits of sequential injection are quite small in the end based on my experience. Biggest difference is at idle and low RPM. More stable idle, better torque at very low rpm (just above idle) and better throttle response. But even on those the difference isn't huge. At top end you may gain few ponies with careful injection timing. On my engine difference was something like 295hp vs 300hp when I tested different timing values. So if you are building a state of the art system and want to optimize everything then it definitely makes sense to get sequential injection and ignition. But if you want a turbo hotrod bike that runs nicely and just happens to be fuel injected then there isn't much point to sweat about it. It will run just fine with simpler batch injection system.

-

Yes, remove the secondary butterflies. On air filter side.

-

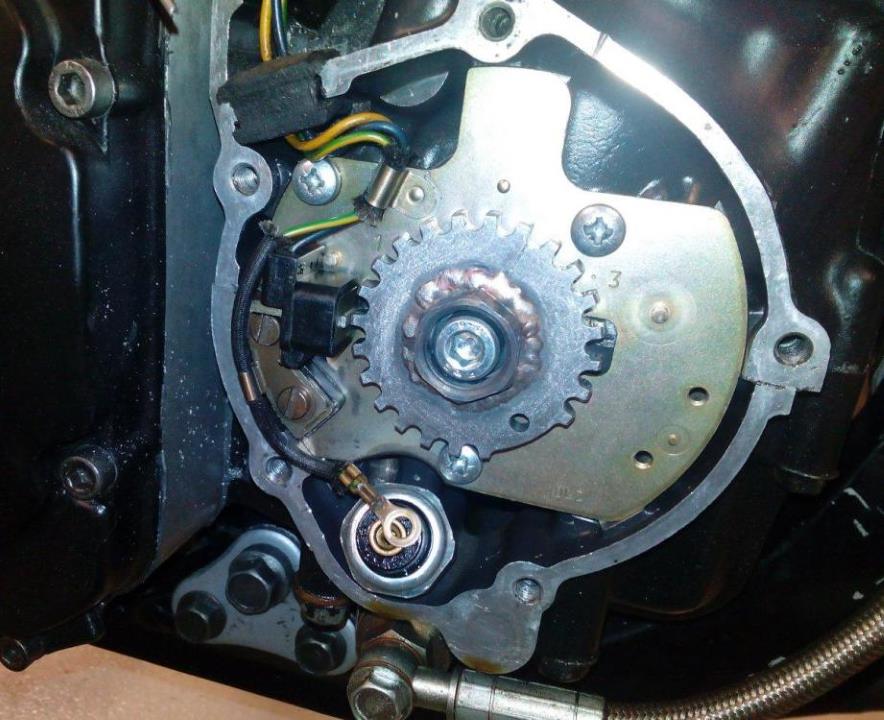

I'm afraid that I won't have time for Speeduino experiments anytime soon... I would guess that an opto sensor might have some difficulties with splashing oil inside the ignition cover. Original pickup sensor is VR type. Oil temp probably works reasonably well as engine temp on these engines. But ideally you would want to measure the head temp. Or intake port temp to be accurate. I have been using sensor on cylinder block with good results. Here is a pic of crank sensor setup. Original VR pickup and 24-2 wheel made for it.

-

This was an oil cooled 1100F engine, right? I wouldn't recommend 36-1 trigger wheel. If you are going to fit it under the original rotor cover the teeth will get so small that most of the sensors will have hard time reading them. Something like 16-24 teeth would be more suitable. If Speeduino supports that. I can deliver a 24-2 wheel that works with original pickup if you are interested. I have never tested the Speeduino but I checked their documentation etc. some time ago. I got impression that it should be quite usable system. However, be prepared for some additional troubleshooting as probably there aren't too many systems running on similar engines yet.

-

Short answer: No, bigger cooler and pipes shouldn't affect to oil pressure. If something they should increase pressure available to crank etc. due to smaller restriction but think the difference would be negligible.

-

Just a guess: A reed switch or something similar to make pulses for traveled distance. Possibly used for self-canceling turn signals.

-

Cometic makes also MLS gaskets for the GSX. Copper gaskets are definitely re-usable. Officially MLS gaskets shouldn't be re-used but I know that people are doing that a lot with good success. Graphite / fiber gaskets definitely aren't re-usable. I haven't personally tried re-using a MLS gasket, yet. I think it would be a good idea to use some kind sealant in that case and copper spray sealants seem to be a popular choice. VHT is one popular choice but like you said it's difficult to get in Europe. Permatex makes similar product (Copper Spray-A-Gasket) that has been used succesfully as well. Should be much easier to source.

-

As long as we are talking about LiFePo4 batteries that are intended for lead battery replacement they don't need any special regulator. Just normal regulator that works should be fine. But updating to modern mosfet regulator is definitely a good idea since they should be more reliable and accurate than old ones. Lithium-Ion batteries would be completely different story. They need different charging voltage and more precise charging control so connecting one to normal charging system is definitely a bad idea. But all these typical lithium batteries for bikes, Shorai, Antigravity etc, are LiFePo4 type as far as I know. LiFePo4 batteries should be relatively safe even when overcharged. At least much safer than Li-Ion batteries that can easily burst in flames. LiFePo4 batteries should just die without any extra drama if you overcharge them. Of course there can be exceptions to this rule. On the other hand overcharging a lead-acid battery can be quite nasty as well in the worst case. Personally I have toasted just one LiFePo4 battery due to faulty regulator and it went like expected. The battery just died, no smoke, no flames, no swelling or anything like that. It was just a brick after that, didn't take or give any current.

-

I did that some time ago. No any special problems if I recall correctly. I didn't specifically check possible frame warpage but I would be surprised if there is any. They are relatively small welds after all. If we are talking about original style subframe tubes. I don't remember how much current it needed but it wasn't anything extreme, maybe 120-150A. I was using aluminium-silicon filler that should be suitable for cast aluminium.

-

Is this good enough? If not, I have a set on table at the moment but it's with oversize liners.

-

Most likely you won't get much power with ignition control. At least on relatively stock engine. With more tuned engine you would be able to adjust timing curve better to match engine needs. And then do some other tricks like that starting retard and ignition cut rev limiter. It should be relatively straightforward to fit other injectors on the GPZ TBs. You have to make a new fuel rail as the GPZ injectors have rare hose connection on top side. Clamping to TBs may need some tweaking as well depending on injector type. I fitted pretty standard "large body" car injectors on mine. They were straight fit except the fuel rail.

-

I was running fuel injection for a couple years on stock GSX1100 engine before going on turbo route. Even though it was relatively primitive Megasquirt 1 based system it was running pretty nicely compared to stock carbs. Biggest difference was clearly improved low-mid range torque but also top end power improved a bit. Like mentioned above GPZ1100 throttle bodies have correct spacing and they go in almost without modifications. As far as I know they are only option with correct spacing. But on the other hand they tend to be rare, old and worn nowadays. In addition they have low impedance injectors that cause some complications too. So I wouldn't put too much effort for hunting them. From more modern throttle bodies GSX-R600 '01-'03 is one good candidate. They can be squeezed to stock intake boots, easy to re-space and 38mm ID suits pretty well for the GSX engine. For sure there are other suitable options as well but finding them will be your legwork And like Coombehouse said using stock ignition and just taking RPM pulse from it to the ECU is fine too. Some tweaking might be needed to get clean RPM information and all the ECUs may not support this kind RPM input. But otherwise it's a sound option if you are happy with stock ignition. And you can always upgrade to ignition control later on if you like. If you want to go for ignition control right away I can supply a bolt-on trigger set for these air cooled engines. It should make things a bit easier.

-

Oil level? in EFE with oil cooler bottom hose connection

Arttu replied to Dukeman's topic in Air Cooled

As far as I know oil level should be checked when completely drained. Of course if you have some huge oil cooler it may affect to result a bit. But I really doubt it will make any significant difference. It isn't that exact science after all... In my opinion bigger challenge is to make sure that bike is in level on both directions as that affects to result really quickly. Nice Kat btw -

In addition of that pinned EFI setup thread Bruteforce's project thread is worth of checking to get and idea about EFI installation process: Some time ago here was also discussion about engine choice between air and oil cooled for turbo project:

-

Better to do measurements and math if you want any reliable result. Always. There are just too many variables that can throw result anywhere. Slightly related anecdote. A friend of mine had a set of Wössner turbo pistons for his race Busa, 9.5:1 specified compression. He wanted to increase compression to 10-10.5 range so we started to take measurements to see what needs to be done. Turned out that with his slightly machined combustion chambers the compression was about 8.2 instead of expected 9.5. With stock head it would be maybe 8.5. After some measurements and calculations we got to conclusion that no matter what cylinder block height or piston crown machining we would use the result would be maximum 9.5 with those pistons. So he decided to buy new MTC pistons with 10.5 compression. So just throw them in and it's done, right? I urged him to do measurements once again and guess what, 9.5 compression with those new pistons! So, always measure and trust nothing. Yes, I know, easier said than done...

-

For IHI turbos here is a list of different models and their specs: https://forums.nasioc.com/forums/showthread.php?t=1141476 I think there are some inaccuracies in the specs but at least this gives you some idea how different models relate to each other size wise and which ones have ball bearings. I have VF34 on my GSX. Works pretty well, about 300rwhp at 1.1 bar and there should be still some reserve available. If you are aiming for clearly smaller power numbers then I would pick something smaller for faster spool-up and stronger mid range.

-

As far as I know there aren't too many cars using ball bearing Garretts from factory. They are mainly aftermarket turbos. Some Subarus use ball bearing IHIs, for example Legacy WRX STi (not all of them, just some year models). So I'm afraid it might be slightly challenging to find good second hand ball bearing turbo for decent money.

-

It's worth of noting that also aftermarket gears are available at 750 and 1100 ratios. I learned this hard way when I bought "just straight cut gears" and later on found out that they were with 750 ratio. Luckily I managed to trade them to 1100 ratio ones. Generally I would advice to stick with 1100 ratio unless you really know what you are doing. There are few disadvantages related to 750 ratio. Like John mentioned the oil pump will spin slower. The clutch gear is slightly too big for 1100 engine cases and some grinding is required to make it fit. Higher ratio also means that you need to use quite extreme final drive sprocket sizes to get total drive ratio sensible. And then at least in theory higher drive ratio makes clutch life much harder. More torque on clutch for the same crank/wheel torque and less rpm for lock-up mechanism.