-

Posts

748 -

Joined

-

Last visited

Reputation

480 ExcellentPersonal Information

-

Location

lancashire

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

great idea to rebuild as a tribute. Plenty of help on here for you as you go along. Look forward to seeing the progress

-

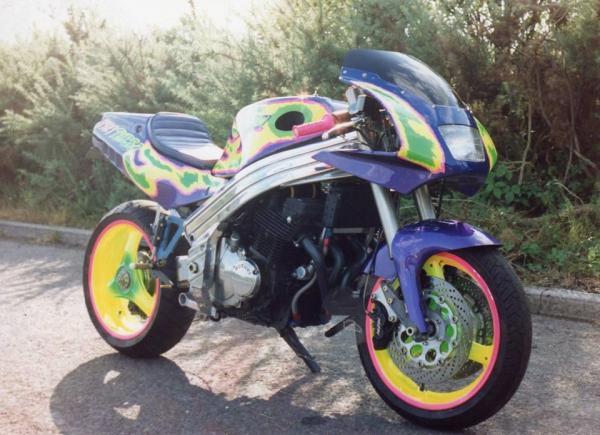

that one above is woodys spondon Katana and is the only one I know of. There was a rumour there were 2 but never seen another. Mick has the only Spondon GIA katana as it was made before they closed the doors recently and is different to the original spondon katana. I have the drawings for the spondon katana. As far as I know there aren't any other ali framed ones. I have seen a copy done in steel and as Clive says there are now steel frames around from when Team Classic Suzuki copied my katana frame to produce race frames.

-

yes Warpspeed stuff is lovely. I have seen some of their full kits and they are very nice. They try to keep the turbo as high up as possible.

-

I was going to buy them but could see you were interested mate We obviously have similar tastes

-

the unclaimed helmet

-

Can I just park my van on your plot again

-

that is lovely. look forward to seeing the progress

-

it is on the bench atm. a lot further on than last post. Might be ready for next summer.

-

good progress mate

-

Maybe they started on the U702 motors which would have been 83 I think. My kat turbo project is using one of these and I cant remember if the crank had any welding or not. it is fully welded now though

-

efe engines had some welding to the crank but not enough for big hp. The earlier GSX motors did not as far as I know.

-

I have seen some of the work at Spondon GIA and it is looking good. To do an exact spondon katana you would need the original spondon drawings but there is nothing wrong with doing an updated versionimo.

-

Spondon GIA is the way forward on aluminium frame kits and swingarms now. They are currently catching up on the backlog of work that Gav had taken deposits on. I have seen their work and spent some time with them and they have some skills and a there is also a lot of spondon knowledge and connections so it is a good combination of the two brands coming together. There will be some articles soon with more details