-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Pretty good result - 1st event, new'ish bike, and silverware at the end! The Boy dun good!

-

Only got my own experience to go by - use Carillo if you want bulletproof. More people are using the Maxspeeding rods and I haven't heard of any more catastrophic failures than 'usual' - thing to watch for is use of fake ARP rod bolts which do fail. Turbo's are pretty soft on rods IMO - i've seen a lot more failures due to oil starvation / delivery failure than pure fatigue. After 68k miles i'd give it a PROPER clean (the amount of shite that collects in oil passages is unreal), check journals for wear (across width and around) fit new bearings - job done. Polishing waste of time unless carving chunks off, balance maybe (especially if changing rods / pistons) but hardly noticeable as they are fairly good from the factory. After a clean, a Magnaflux inspection not a bad idea though!

-

Depending on cam timing, at least Super Unleaded maybe race gas 105/106 RON, maybe more.

-

Yes - invariably there will be slack in the chain and that idler pulls it into the center moving the cams around. Easy way around this is to put cams in correct place and 'karate chop' the slack between to two cams. This acts like the idler and shows if they are right or a tooth out.

- 1 reply

-

- 2

-

-

Probably no help but SE outer dia. of a Falicon 1127 rod is 25.8 ish mm. as I can't be arsed to dig through the 'old stock' crap pile at the moment LOL!

-

The more and the bigger - the better! Tee'd together breathers whilst not catastrophic can only equal the single exit pipe area which defeats the object of the first point!

-

Really? They ain't that good even when used in the bike they were fitted to originally and for racing ? ? ? Too heavy, too many disc's and too poorly sprung / damped! There must be loads lying around unused in sheds after being swapped out for decent tackle?

-

Easy way to 'throw away' horsepower - been proven. The gauze may filter rocks and gravel but sand and smaller - straight in! A good filter loses nothing and gains engine life. They probably make no difference on the HD application and hard to lose what you ain't got in the first place LOL! The throttle pump exercise is about the std. way for carbs without choke's - even works with RS flatties & they have a choke !

-

Simple answer NO! All oil designed to go through cooler before bearings so you effectively starve everything. With some careful measuring, cutting and welding, you could cut the elbows down to the straight bit, turn to face each other and weld a sleeve over the two - short, neat and inconspicuous!

-

I suppose it depends on how efficient the pump is and what turbo bearings are fitted! A average pump and ball bearing cartridge will be running mostly dry due to low flow requirements, whilst a good pump and trad. plain bearings having lots of oil flow could drain the sump and, without a vent, try to suck oil from the turbo bearings. Maybe unlikely, but the addition of a vent breaks that suction risk I guess?

-

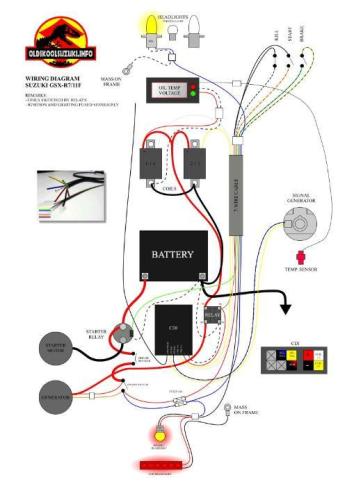

Wiring Harness recommendation for rebuild project

Gixer1460 replied to Mike-Polito's topic in Air Cooled

-

We did (big $$$ engine on nitrous) and dropped a few valves, never a seat!

-

They do, same as most 4V engines will - the GS1100 / 1150's were notorious for it and they still run fine so don't dismiss a head just on that reason. Although its a good bargaining point if buying

-

Cyl. Head oil drainage tubes - DON'T use anything other than Suzuki parts for these o-rings . . . . . many have tried and ended up tearing the engine down again due to leaks!

-

There is nothing in MOT guidance that precludes use of alloy fittings on a road bike. There is guidance regarding leakage and corrosion - for ANY flexible brake line, so none are immune. But like anything, if you show up for an MOT with clearly corroded and / or split, leaking or otherwise deficient brakes, then you deserve to have the book thrown at you. Also note, that some of these faults are noted as 'Dangerous', meaning the vehicle has to be fixed before it can be used again - even to take home to repair! I'm not preaching as I have and do use alloy brake fittings on road bikes but they don't get salty or wet! My usual preference is Stainless for 24/7/365 type use!

-

The chamber don't look so bad and consistent with a broken ring BUT the chunk out of the side of the chamber isn't from a busted ring! Looks close to fire ring of HG - needs to be checked. Also valve seats need checking for damage from broken ring pieces!

-

Gsxr1000k1,2,3,4 pistons

Gixer1460 replied to clivegto's topic in Water Cooled, V-Twins, Singles and 2-strokes

If it was, he was too late, so cool on him! -

Gsxr1000k1,2,3,4 pistons

Gixer1460 replied to clivegto's topic in Water Cooled, V-Twins, Singles and 2-strokes

Is this a real post? Never read such mis-guided, crock-o-shit comment! Pray tell us how long a stock piston will last with 12.5:1 CR over it, or 100hp shot of Nitrous or 15lbs of boost ? ? ? -

A complete ex. system is worthwhile just for the weight it saves - std. bindit is double skinned back to the collector & link pipe so weighs a ton and when it rots, it does so internally and then rattles! That'll help with the suspension which is built down to a cost not up to a quality - HyperPro springs up front, seals and an oil change, + a decent shock at the rear will improve usability no end.

-

If you click on users name in a thread, the site spits out all their stats and location - just for info!

-

And BTW - if you've read the forum rules - you'll know that 1200 bindits are good engine donors for other sickly oil boilers LOL!

-

750 WP with VFR 750 single side arm

Gixer1460 replied to Ade's topic in Water Cooled, V-Twins, Singles and 2-strokes

Apart from being out of focus - what's the difference, save the neon blue, wheel rim stripes ? LOL! -

Sorry - I see no contradiction? Exactly the same advice! And same as repeated above.

-

Normally if vacuum isn't required then line's should be plugged otherwise you have a huge air leak