-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Oil Boiler Blandit 1200/GSXR1100 Eaton Supercharger Setups

Gixer1460 replied to rider384's topic in Forced Induction

A BIG one and really it should go between the supercharger and the cylinder head as Eaton chargers are pretty inefficient, so will be taking already hot turbo boosted air and making it hotter! -

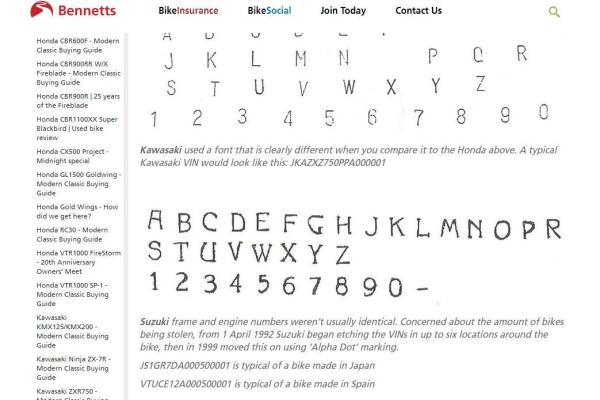

Found this below from Bennett's who know a bit about 'faking stuff' for insurance fraud - quite informative but not definitive! So, using the above info the frame number looks correct ie. font / type face and 11 characters seems correct. The engine number though - hmmmmm! The 'A' is clearly wrong, likewise the '1', the '3' and the '9' - only the '5' is about right. This doesn't mean its wrong or nicked or a knock off - dealers had the ability to stamp virgin cases from spares which came without.

-

No - think about it . . . . if the small dot is neutral, the shifter pawl goes past this to the blank bit for 1st gear ie. nothing needs to happen in first. Then changing up you pass through neutral, get 2nd then 3rd. Changes after this to 4th and 5th have no electrical outputs as nothing is required so there are no dots / contacts. I would guess that in the std suzuki ignition, when it sees that it is in 2nd it applies a bit of retard (to quieten the engine for noise tests) then when 3rd is selected it knows 'full power' settings can be re-established. Trying to diagnose electrical wiring and set-ups is difficult when they are not in front of you - so I can't speculate on what or what not to do, or what happens when wire A is connected to wire B etc. Sorry!

-

The ET variants i've seen have 5No brass dots + another, which is for neutral (usually between two equally spaced 'normal dots') Blandits have a similar arrangement but only 3No pins - 1st / neutral / 2nd. - this is to activate retard for noise tests! Busa ones are again similar but have 6+1 dots (6 gears obvs) but is a three wire system - 5v in / Ground / and gear volts out. This allows the Busa ECU to different gear based shit that most mortals don't understand. Your one seems to be missing some dots / contacts - maybe why it switches in 4th? I was working on using something similar in my turbo GSXR but wired like a Busa one so it would talk happily to my AMS1000 to allow different boost ramps / targets for every gear - good idea for a road bike, me thought! Yours doesn't seem to have a lot of wires so i'd suggest using a multimeter to see what is connected to what - a) to get full understanding and b) how to change it . . . . if you ever want to ?

-

We have a winner! That's how different boost available - oldskool, but it works!

-

Is the neutral switch 'just' a neutral switch? Not beyond the realms of possibility that a GSX type switch has been fitted that provides a separate ground via separate wires for each gear - that makes a pretty sensible solution given the box limitations?

-

I trust you've read the manual? - https://www.manualsdir.com/manuals/570456/precision-turbo-and-engine-nlr-ams-500-boost-controller.html Just on a brief glance it looks a damn sight more complicated than the AMS1000 i've got - but I haven't used mine for years so probably forgotten how anyway LOL!

-

Depends on what you need - I prefer having loads of oil volume through cooler by using -10! Big horsepower needs big cooling!

-

Re : the swingarm, my first thought was a bottle jack between, go slow and 5mm should be achievable! Pistons must be really old as no one seems to engrave the tops anymore! XC rings should be easy to get - decent engine builder or at worst Bay of E ! Bus rods - ask engine builders who build big HP turbo engines as will usually swap out rods for Carrilo, Falicon, Eagle, Arrows etc. or again Egay!

-

Well, having Red permanently connected to the Orange is a bad move as all the circuits will be permanently live inc. ignition so you'll possibly overheat the coils and flatten / kill the battery through deep cycling! Lots of people delete the sidestand switch. I know it may be difficult to get your head around but just pick one circuit at a time - follow the circuit / wiring diagram and use a multi-meter to check for a) voltage and b) continuity (ie wires not having a break within the loom)

-

fuel injection on an old skool motor ? who has done it ?

Gixer1460 replied to busa ash's topic in Air Cooled

Arttu is the Oldskool EFI guru - running a efi Turbo'd GSX, plenty of others done - mainly on the oil cooled variety, but an engine is an engine regardless! -

First off - just swap plug lead from #3 with #2 and vice versa - if the problem moves its electrical, if it stays its carb / fuel related (probably!)

-

Looks std GSXR11 with a different rotor - using that with std GSXR11 CDI will confuse the hell out of it. So, could you use the std GSX14 ECU running ignition only if using carbs fitted. Will the ECU actually work if it doesn't 'see' any injection stuff - possibly throw up errors? Are you talking GSX14 or GSXR11/7 'CDI' as the former is strictly an ECU. Otherwise see reply above. Its an interesting concept nonetheless!

-

Symptom all the time or does it run ok and then problem develops? If latter them maybe look at coils breaking down as they get hot - they are likely 40+ years old now!

-

No - it wouldn't work as the 1400 ECU needs the 1400 rotor which if memory serves me right, is on the starter clutch / alternator rotor like Busa's etc? To use a GSXR oil cooled ignition it has to be complete system - CDI, rotor and pick-ups and conversely EFI conversion needs the whole install so the ECU understands the signals its getting or not getting! EFI conversions are better served with aftermarket ECU's for flexibility in component selection.

-

Brilliantly explained - I doubted my explaination as it's been a few years since I've been into one of these heads! Sorry for the mislead!

-

Easy on the attitude fella! You're asking for advice / posing a question - don't get pissed if the answer isn't exactly what you want! In answer to the Q, I believe there is a pressurised oil gallery up those studs that runs out to the cam caps to oil the cam bearings - the O rings stop that oil leaking away! And the OEM O rings is good advice - Suzuki use non standard O ring diameters - many have tried to 'cheap out' on critical O rings and gaskets and suffered oil supply / drain faults . . . . . . . penny rich / dollar poor in long run!

-

Just compare the cross section of the 'std' 492 rod with the 493 Katana rod - its no wonder they are sought after for anything upto and including Funnybike engines! Not sure who thought those wimpy rods would cope with 200hp bearing in mind they were designed for 110hp? plus a bit of headroom - maybe 150 ish tops?

-

If it is an aftermarket one, fixing it will likely mean replacement! Honestly they are more for show than being useful - a few weeks riding and you get used to how bike sounds and feels and gears will become 2nd nature. As said a picture to confirm would help.

-

Sorry can't do 1100ET - but do have 1150EF/EFE, 1100SZ Kat, or 750ET if any help?

-

This will piss you off then - Just sold SWMBO's trike this morning, hasn't run in at least 5 years, turned on tap (with whatever fuel was in there), pulled choke and it was on jump leads but fired up after about a minute of cranking & some EasyStart and sat ticking over, smooth idle after 30 seconds . . . . . . . . amazed me, stunned the buyer - life can be like that I guess LOL! I guess you are lucky that fuel stayed external and you didn't fill the crankcases ?

-

IMO - its not necessarily HP that does cranks / rods in. Its instantaneous acceleration's / deceleration's like missing a gear at peak rpm's that tend to twist cranks. A good working engine will sustain a lot of revs and HP - but drop a cylinder due to a misfire and that won't help crank longevity.