-

Posts

5,758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Not here for an argument but several Drag racers tried ceramic wheel bearings back in the 90's and 00's. Ceramics are actually harder than steel so a Ceramic ball on a ceramic track should last longer and without requiring lubricant as well. Brad O'Connor did some calcs based on the claims for the bearings and deduced if they were true, a steel bearing should heat up to the equivalent of about 100w ie. you should be able to feel distinct warmth. He never found this to be true in the real world, so draw your own conclusions. They are good bearings and are very low friction but unless you are sponsored would you use them? Probably not! Steel bearings DO heat up if you push them to the extremes of their operating window ie. machinery spindles rotating at 20k rpm and Land Speed vehicles going mile after mile at V max! These applications must use 'special' greases in correct quantities - they are that fussy!

-

Those 'filters' will lose you a few hp - Dyno proven. Might keep bugs out but do no good for airflow unfortunately!

-

If you want a direct replacement then go aftermarket - Electrex is a trusted brand in the UK. You could spend hours searching for an OEM R/R that will fit directly. Most are happy to use one mounting bolt and either use another hole or add a bracket as necessary - its not rocket science.

-

-

The light switch thing was Suzuki's attempt to ensure the headlight got max volts when on. When off it just overheated the R/R as that voltage not used had to be dumped as heat! Easy conversion is buy any decent modern R/R - they'll usually have 3 yellow wires, a Red and a Black (or green if its from an 'onda) Connect the yellows to the three wires out of the ET generator, connect the Red to battery and Black / Green to ground or battery - (makes no difference. As the light sw. no longer gets power from the generator, take the wire that did supply it and connect to an Ignition Switched Live so it only gets 12v when Ign is on. Adding an in-line fuse to this wire would be good idea - 10A would be sufficient.

-

Banding is piss easy with steel wheels - still done with UK stock cars and other eccentric type sports - trials for example but a cast alloy wheel ? ? ? Nah!

-

Still applies - just not the going round corners bit

-

I did say 'pretty much' and as we are talking about two later oil cooled engines your point is irrelevant LOL!

-

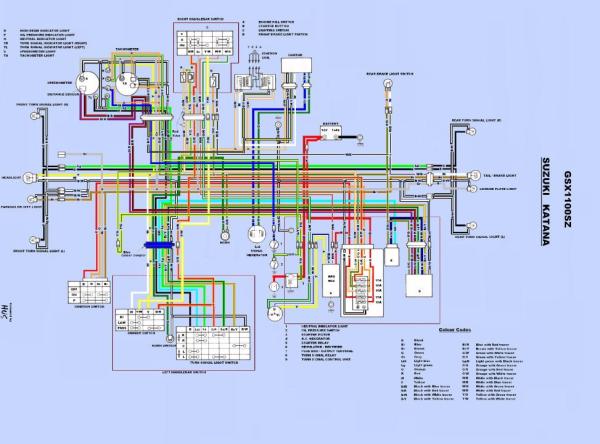

F**k me doesn't anyone ever bother looking at wiring diagrams anymore ! Suzuki San has pretty much used the same colours for their loom since the Dinosaurs were around! You need to worry about Orange / white (12v+), Black/Yellow (coil 2&3), White (coil 1&4), Black/White (ground), Black/Red (or Red/Black) ((tacho signal), Blue (Ign pick-up) and Yellow (Ign pick-up). Everything else is Blandit related and not required to run a 'normal' oil boiler. BTW - Suzuki tacho's will often over read by 1000rpm and most engines are well past their power peak if approaching the indicated red line so having a 10 or 11k red line is largely immaterial!

-

Unfortunately yes they will. Any piston down the bore, will not / cannot have any beneficial squish! Whether it makes a big difference in the grand scheme is virtually impossible to quantify unless you build two engines one with and one without squish and measure output back to back! If you want any possible gain then pistons with required squish and to suit the application is a recommendation. IMO a piston with a dish and valve cut outs in the squish band, not utilising squish principle risks increased chance of detonation / uneven burn as mixture lingers around the edge / cut outs and isn't forced into the bowl. Its a take it or leave it situation.

-

You're going to Cop it now - Kats never had oil cooled, 11,000 rpm engines - no matter what the US importers called them! But in answer to the question - what is the problem?

-

Well according to the OP - It is a 17" already? So who is right?

-

What has the diameter got to do with the request? Personally, I wouldn't try reworking a near 40 yr old Japanese cast alloy wheel if my life depended on it!

-

Which is most common cooler or lines leak... Bandit 1200

Gixer1460 replied to BikeJake's topic in Oil Cooled

Welding any oil contaminated metal, steel or aluminium is a total PITA! No matter how clean you think it is, with heat, oil will boil out and ruin the weld. Not saying it 'can't' be done, its just new will be more cost effective! -

I'd disagree there - my 1127 with a 1186 kit made a tad under 20 rwhp more with no other changes other jetting - just sayin like.

-

Not trying to piss you off but a stock engine with some subtle mods AND fitted into a fully sorted / adapted chassis will do 8's NA. Hell, there used to be 2 stroke sub 500cc bikes that run lows 8 / high 7's in the UK. Power doesn't get you out of the hole consistently - chassis performance does. Chassis for time, HP for Speed, and in drag racing speed wins jack !

-

Ditto! A welded repair would need heat treating but with a cast steel crank not so easy!

-

Ring Gap, Stock Valve Springs/Valve Questions

Gixer1460 replied to rider384's topic in Forced Induction

With your target HP, I think you'll struggle on pump gas in CA! Way back my GSXR made 370hp on 110 RON race gas and it is a 1460! Boost was maybe around 2 bar! Boost affected valve float can be down to either piss poor spring pressure or excessive boost. With GSXR sized valves I think you'd be into VERY big boost or you'd forgotten the inner spring from a dual spring set up! Using big lift / duration cams doesn't help valve cooling - minimising seated time is what burns / melts them. It doesn't take much either to start making the stems malleable, then the heads snap off + carnage! You are trying to do two different things with one bike . . . . . . a 'ridable' street bike ie. good manners, doesn't stall or over-heat during use and also a Top Speed miler. It may only be 'for fun' but the engine don't know that - all it knows is you are asking for WOT for a mile+ and that is a lot of power / heat generation and for that application cooling = drag = slower! As regards ring gap, a 'maybe happy medium' would be 0.006" / 0.006" - it may smoke a bit but shouldn't seize especially if you do make the boost for 400hp. -

Could be fuel but also Ignition - excessive retard or no advance from idle wouldn't help! At low rpms quoted there shouldn't be excessive heat - something is wrong, not bad tuning - its wrong!

-

? ? ? ? - those didn't have 36mm's only 34's. It would appear that Suzuki San standardised the inlet spacings on the GS / GSX 16v engines through to end of the oil boilers so most will swap around.

-

Unfortunately yeah - its knackered / well past its best! Compressions should be around 150 - 200psi with minimum about 140psi! with approx 25psi variation cyl - cyl. Oil pressure (hot - 60 deg C) should be between 45 and 85psi, cold it would be nearer the 85 than 45, so looks like the pump, isn't! Its getting rid of the oil somewhere and at a guess, its bypassing the rings! Regarding being 'hot', have you checked ignition timing?

-

Arttu, Only say as I find. Fitted a new clutch to a 1200 Bindit (fibres and steels) used Mobil One oil and clutch lasted approx 50 odd miles. It felt 'odd' from the off and eventually the fibres glazed over and it spun enough to blue all the steels! Never used fully synth again, never had a similar problem. This was a good while ago and synth oil may be better these days 'but once bitten' as they say.

-

As an aside - there is no need to use 20w50 oil in this engine. There is no benefit (unless you are maybe in a desert @ 40+ deg C) and the increased viscosity leads to increased drag. 10w40 mineral was recommended back when new but modern oil technology has moved on so similar weight oil using SEMI synthetic formulation would now be acceptable. DO NOT USE Fully Synth oils - even Bike branded ones as they are too slippery for old clutch materials! As said - any engine over 55-60 deg C is pretty much untouchable - 100 deg C is boiling water temp . . . . would you stick your hand in a kettle? An IR thermal heat 'gun' is a better tool than a gauge - just check after a ride. Sub 100 deg C and you are fine, over and either a cooler would be a good idea or halve your oil change routine so oil doesn't get 'cooked'

-

it is, or at least it was! Who knows if its survived the EFI onslaught LOL! Used on Froggy cars a lot so lightly a metric thread compatible with Jap carb as would sizes - still sounds too big though!

-

Most of the time if you 'hear' knock, damage is already done! Is this the stuff you are dosing with - Wynns Lead Substitute, 250 ml ? If so, you are massively overdosing as 1ml doses 1 Litre of fuel ! And @ £10 a bottle it'd be loads cheaper to fill up with ESSO Super which is ethanol free and 98 octane. BTW - lead isn't needed in any Jap bike since the 70's. Is the DOT head on a Blandit or GSXR type bottom end as at a guess, you maybe over 12:1 CR without much overlap to mitigate it. Heating up an engine can be caused by lots of things - CR is one, jetting is another, low cooling and ambient temps won't help nor will over advanced Ignition etc. Putting 'cool' plugs in won't help cool the engine - they run cooler themselves by dumping temp into the head, so they may reduce 'pinking' but will also foul easier as they can't burn off the contaminants as easily! You have all the ingredients to produce knock, so why not minimise those first as you'll likely have to address some if not all of them anyway? Usual tuning position is Start Safe then move towards limits - you sound like you may or may not be at the limits without knowing where safety actually is. My approach may be cautious but it works and I've never needed / used a knock sensor yet. BTW, are you using electronic, mapped fuelling / ignition control or Carbs and 2D Ignition?