Zenerdiode

Members-

Posts

17 -

Joined

-

Last visited

Reputation

4 NeutralPersonal Information

-

Location

Newcastle, England

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

There are two metal studs on the bottom of the guide that form the pivot. They are captive in the top crankcase half so yes, cases have to be split.

-

I’m struggling to find the three cam chain guides for my GSX750 ET. I’ve tried CMS, Fowlers and a few others - to no avail. Suzuki Heritage say they’re no longer available. I fear second hand ones will be as worn, cracked and brittle as the ones I’m trying to replace. Would anyone guide me to any aftermarket ones, etc. please? Or is there such thing as re-plasticising my existing ones? Thanks indeed.

-

I think you’ll be better off buying a new seal, taking the ignition trigger stuff out of the way and tapping the new seal in. If you split the cases again, the seal likes to stick to one half and if it favours the ‘wrong’ half, you’ll stretch it and wreck it anyway. You didn’t say if it was leaking from around the shaft or between casing and seal.

-

It’s not, erm, it’s not ‘123’ is it?

-

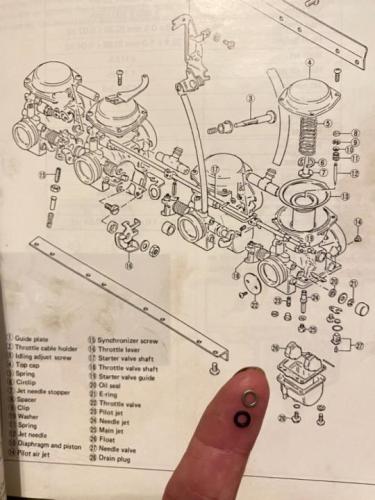

I’ve stripped my carbs and buzzed them through the ultrasonic cleaner. When I emptied the cleaner, I found 4 x each of the tiny o-rings and metal washers in the bottom of the tank as shown. They don’t appear on the drawing in the manual, are they from under the pilot screws? If so, what is the order of fitment? Many Thanks.

-

Don’t do that. There’s a controversial guy on YouTube who’s recently posted a video of doing just that. There’s no point in placing a comment, as anything even slightly critical (even constructive) gets deleted. Any shit in the dirty fluid gets pushed up to the master cylinder and the tiny lip on the cup seal is less able to deal with particles than the big square seal in the calliper. The new and old fluid mix as it creates little fountains and vortices in the fluid. Finally, the bleed nipple is at the top of the slave cylinder for the obvious reason. If you’re back-flowing through the bleeder, you’re bound to admit air, that will not make it through the calliper to the reservoir - so will have to be purged in the conventional way.

-

I bought my GSX750 with a blown engine. To recap, one of the tappet adjuster locknuts had jumped free - and found its way into the cam chain. Chain snapped etc. It’s been a while, but I have liberated the crankshaft and I’d like you guys to take a look and see if it is repairable. Two teeth are broken, they are on directly opposite sides.

-

You’ve answered Dezza’s Question 1) then.

-

Rather than just changing the bulbs for LED - there’s a few folks here that have fitted an LED cluster. Others may correct me, is it a Jeep headlamp that fits?

-

Have you knocked any glaze or shiny spots off the plates with a bit of emery?

-

What’s TSP solution, please?

-

It sounds more like you have described the symptoms of a failed needle/float valve for carb #1. If the level is going much higher than what you’d expect in the bowl; the mixture is probably too rich for cyl #1 to fire. If the petcock has failed (which indeed it may have as well) when running it would have no effect, as it’s ‘on’ in any case. So when the engine is not running and petcock in ‘Prime’, the bowls should fill to their fuel height and shut off. The petcock is really just there in case the needles weep a bit. Have you checked the fuel level in all of the bowls?

-

So the GSX750 was bought as a non-runner. The engine in the bike has a snapped timing chain, it came with a ‘spare’ engine that apparently burns oil like petrol. So I’ve decided to see if the snapped chain engine can be repaired - it’ll need to come out either way. Removed the rocker cover; yep, no chain. Took the head off; and there’s been contact. Also, make sure you check your locknuts after adjusting valve clearances guys, I found one that escaped. It was still in the head, so I don’t know if it contributed to the chain snappage. I’ve filled the ports with fuel, the inlet valves are still sealing. Then removed the valves and as far as I can see, they haven’t bent so I’ll lap them and I think the head is serviceable. I removed the barrels and the top ring of each piston has snapped, but no scoring of the bores. The bores may require a very light hone or at least a glaze bust. Any recommendations on where to get the rings? CMS? The crankcase is still in the frame, I don’t have anything to lift it out or support it as I do so. I was looking to split it in the frame, but he frame gets in the way of a couple of the journal/case bolts underneath. Any suggestions on either getting the crankcase out or splitting it? I can see the chain all mangled up in there and hoping it hasn’t taken any teeth from the crank sprocket.