-

Posts

8,339 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by clivegto

-

Would have thought Hindle will make one to fit.

-

Bang it in and go have some fun if you must. I would hold of and build my own motor then go have lots of fun

-

-

-

Now have a working back light, horn, indicators and clock face. Wired the fuel pump into the kill switch. Still lots to chop out and shorten.

-

Mk1 busa rods to fit your pistons with a 2mm spacor plate under the block will keep costs down.

-

The black lines will melt if touching the exhaust, don't ask me how I know this

-

There was a subframe as well that's not in the picture.

-

Arocoat in Yarmouth was a bit pricey at £250.

-

-

Chrome powdered on one of my frames. Very shiny when first done then fades a bit, it don't like oil takes the shiny stuff away.

-

What is it breathing for exactly.

-

Some say the cooler is better fixed to the frame so no flex in the oil lines. I fixed myn to the forks, there's only 10mm movement with the oil lines which is nowt when you start to think about a JCB back arm.

-

Thanks and yes I did.

-

Have noticed the indicators need to point in the right direction even though at a glance its not noticeable.

-

If you happen to be visiting North Yorkshire in the next few weeks please feel free to call in to give me a hand with the loom.

-

-

So I sleeved the indicator stem up, think it looks better like this obviously it will be painted black.

-

Small bit of stainless steel 90° angle mounted to the carb rubber mount. It's not rocket science lol.

-

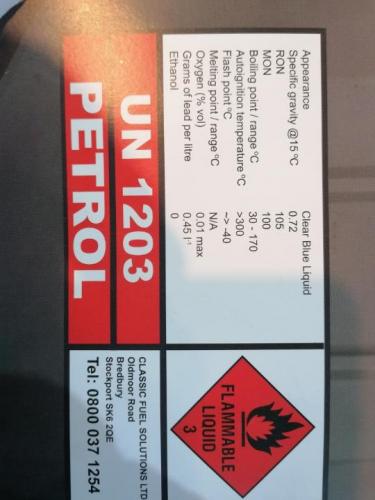

I use shell from local garage 1/2 mile from me 99ron,never had any problems. But also came across this at Caldwell Park in the pits.

-

Swap the cogs over and be careful refitting it as FB says.

-

.thumb.jpeg.45eb6ba837ac2d0b81d2d4f284e2c6af.jpeg)