-

Posts

8,296 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by clivegto

-

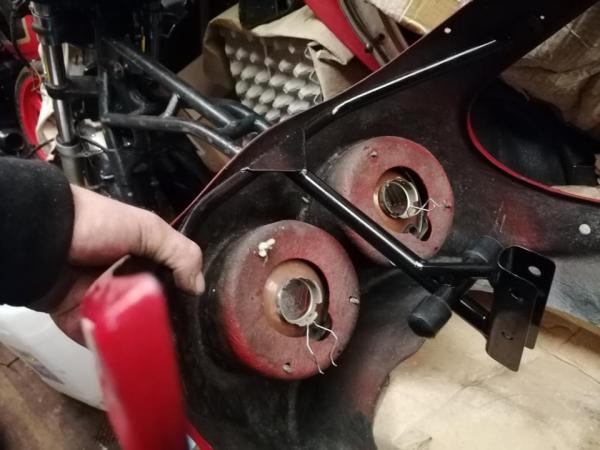

Nice looking bike that is. Fairing bracket is for mk2 faring.

-

Sometimes it does overflow. But not as many as Will .

-

Just a little bit more to the puzzle. John Schoon made me a rather nice faring stay which I picked up at Stafford bike show.

-

-

Came across a Ducati swinging arm that had been fitted to an EFE frame with Spondon drag slots at Stafford bike show so I promptly bought it along with the frame too egged on by @Paulmand @imago

-

-

-

It has a 750 motor in without a turbo now.

-

Yes, Barry likes stuff out of the norm.

-

Home made, a mate who is a bike dealer has it for sale. I nearly bought it.

-

-

-

Not touched it for 3 weeks, pressed the go button and the beast fired up on all 4 cylinders. So seen as Stafford bike show is next weekend I went to fit the seat unit which didn't fit had to re do 2 of the fuel line's to get it to fit. Went for a spin down the lane and all appears to be good apart from the front tyre is low on pressure. So am happy for now, just needs going over with an oily rag to clean it up for the show next week.

-

I don't think it is, just to stop clutch chatter.

-

My efe one drags a bit if that's any constellation.

-

You need to do your own measurements on a dry build and calculations as every engine can be different.

-

-

-

I fitted a 1100efe one to a B12 bottom end in my Harris.

-

Make a copper one.

-

Don't know yet but the one on @caferacerdanwheelie bike made good numbers until it blew the head gasket.