-

Posts

2,249 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by jonny1bump

-

Its never going to fail with welded boss.

-

Im glad this post of mine is helping out took me ages to realize why i was cooking so many batteries. Alternator is quite simple has voltage on wire from ignition and output wire they need to match if not alternator ramps up. Without feed wire on alternator will not work its what wakes it up. Sound like control side alternator about to go check brushes first see they stuck or worn also if battery us and close to dead short that cause all sorts of Choas.

-

As above but if changing found dyna mini coils good there normal coils junk had several fail for no reason even rubber mounted as thought vibes was issue

-

Did some testing years and years ago and found 1 degree extra advance was all what was needed but again no 2 engines are the same depends on whole set up. That's beauty of full programmable ignitions if you have a rich spot you can advance ignition just at that spot to try increase burn at that point.

-

-

-

-

What is the weight saving.

-

89 GSXR1100 1127cc to 1216cc JE Kit, general engine building questions...

jonny1bump replied to SBK1000's topic in Oil Cooled

You may be surprised what compression you can run with 97 with the correct set up, but quite correct over 13 stock fuel is problematic. -

Clive remember on the stocker we do clutch every run, you may now be at this level with your set up that is starting to warrant this.

-

89 GSXR1100 1127cc to 1216cc JE Kit, general engine building questions...

jonny1bump replied to SBK1000's topic in Oil Cooled

Good Head work, valves will give biggest gain for you buck as they day. Je pistons I have found to be better quality to Wiseco. I just ordered some new rings they all made by same company. Stock rods are better then you would think. Everything being said above depends how far you want to go. Its quite easy to get to 150 even with stock carbs jetted and airbox. After this starts getting costly and time consuming. -

I agree. If ya really in trouble throws up another option at least.

-

Hope it goes well for you all.

-

Is it spinning up Clive so you punching early in the lower gears. As your geared tall really need to let it rev less gear changes too may save a tenth or so.

-

Thats serious anorakism. Awesome work.

-

Fair enough.

-

You only got small holes the side of the banjo bolt thou ?

-

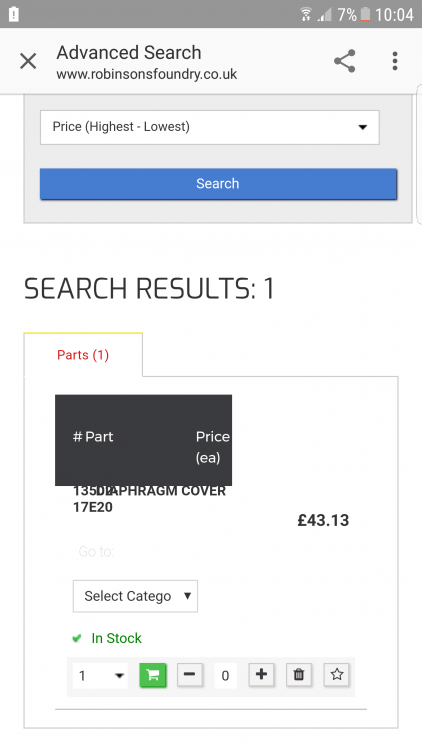

Think you get 10 percent off too if tell them member of here.

-

Im impressed with dyna new mini coils, I had a new grey coil fail in very short time and customer service was not too good.

-

Im being picky here but you have reduced diameter of bore so its not going to breathe as good. These motors gotta breathe.

-

Nice improvement Clive 158 mph no mean feat well done. I have herd rumblings may be bull dog next year. Was it good this year in general. You going hot rod drags. You got red line set at 10500 in reality then, with how Suzuki tacho read high, for road machine too, best not to rev it more.

-

Light switch on, electrics power off, daylight only, bugger

jonny1bump replied to richyrich's topic in Oil Cooled

If you look at the wires you find most of them are now black almost impossible to solder and dont join too well. Also you see a post years ago which has being re written many times i did about charging circuit which is complete suzuki insight failure. I think most of us on here with projects have junked the stock loom and made our own its basic loom at end of day but still can be simplified. Looms very time comsuming things to do but worth it and if using dyna ignition then you can split loom into ignition and seperate the rest. -

It really does depend on head work too and how much valve seats have being taken to limit. I had head taken way to far adjusting clearance every 500 mile. My m / l head conversion which ray cut seats for me has lost 1/2 thou in ridiculous amount hours of use but i had also hard welded rockers, etc, etc all makes difference including oil. Valve clearances normally close, as valve hammers into head unless using bad oil, long storage times and worn cams etc, etc. Basically really depends on what you done to engine so very difficult question to answer.