-

Posts

1,921 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Joseph

-

Engine mods and other upgrades for a 92 GSXR 750?

Joseph replied to Upshotknothole's topic in Oil Cooled

It required quite an effort, the glue must be something like windshield glue, its very sticky and will stay on your skin, then the whole thing is hot so not great to hold tight. Then the trick is to lever it out without deforming the plastic frame which of course is warmed up and malleable. To be fair, when i did it, it was to put in that custom light and re fit the glass. In your case i'd heat it up to soften the glue enough, then put it in a bag, smash the glass with a heavy hammer and then you can easily take out the parts from the frame without putting too much pressure on the plastic -

Yes, the 34mm carbs have a single fuel inlet spigot cast into the body of carb no. 3 (i think) whereas on the following racks the fuel plugs into the pair of plastic t pieces that bridge each pair of carbs

-

Would GSX 1400 which are 81m and i think same diameter wrist pin be any good ? Comp is low at 9.5:1

-

I now only use Supersprox on mine, they make steel teeth sprockets riveted to an aluminium rotor, very good value/quality/lightweight and of course they take custom orders (for example here a Ducati 749 rim for my 1100R, standard sprockets off the shelf for those stop at around 40 teeth) And to run proper gearing on a slabside rim with 1127 engine i needed to have one made

-

Engine mods and other upgrades for a 92 GSXR 750?

Joseph replied to Upshotknothole's topic in Oil Cooled

I think it weighs something like 8 kilos ? The glass is around 8 or 9 mm thick it's very heavy indeed Best to use the right one though, it'll just slip into the fairing hole and can rest against the plastic headlamp frame too, then you can make a period style fixing of it onto the fairing -

Engine mods and other upgrades for a 92 GSXR 750?

Joseph replied to Upshotknothole's topic in Oil Cooled

To fit those hi power led strips I designed a plate that was laser cut, tabs welded, then fit to the headlamp bowl, both were powedercoated black and then reassembled the whole package -

Engine mods and other upgrades for a 92 GSXR 750?

Joseph replied to Upshotknothole's topic in Oil Cooled

Spatulas for plasterwork are a good tool for the job (a couple of narrow 1-½ inch wide blades) it's a difficult job to do even once heated up, that glue wasn't designed to leave its place Propane heater should be good. A heat gun won't allow heating of the whole thing, and you really want to get it all up to temp evenly all round (the heat gun is also too hot for the needs of the job) I put the oven on at 210-220°C to do mine Just noticed you have the american 92 bike, the link i posted is for the WC '92 -

Engine mods and other upgrades for a 92 GSXR 750?

Joseph replied to Upshotknothole's topic in Oil Cooled

Yeah i did the oven door deal You can just buy a headlight protector cover fixed on with little tabs https://www.slipscreens.co.uk/product/suzuki-gsxr750-wn-wp-gsxr1100-wn-wr-headlight-protector/ -

Chemical polishing (?) Could be ideal for our frames, it passivates alloys to prevent any corrosion (up to 10 years supposedly) and you can get it to as shiny as you want. The chemical compound seals the finish However i suppose it would be a budget and like chrome you need to find the guys who have a big enough tank PC is good but thick as we have all seen, but it's probably the most cost worthy and durable finish for a bike that you want to use a lot

-

Slingshot 1100 RS38's setting might help out some

Joseph replied to alfiestorm's topic in Oil Cooled

Yes that is definitely the plan once it's back together, every engine is different, one of those things where it's "same not the same" -

Indeed that chamfer deal. However it's funny because the ignition pick up plate is the same part number for absolutely every single oil cooled bike from 1985 to 2008, except the RK. Maybe it's made of alloy or something ? Didn't hear back from the guy who bought one of my adjustable plates so i'm guessing it fitted fine

-

Slingshot 1100 RS38's setting might help out some

Joseph replied to alfiestorm's topic in Oil Cooled

Oh quite fruity then I mean mine doesn't hang about but i don't have much to compare it to. I need to finish getting it back together, i'll see to getting dyno testing then -

It's "easily" done, but it's a bit of work and head scratching You need to fit correct bearings to the rim (smaller spindle on the W, obviously) Compatible bearings are available, that match the OD of the rim bearing and OD of the spindle. Then its a question of fitting the rim, and centering it in regards to the frame and front wheel ( !!! The centerline of the rear wheel spindle is NOT lined up with the centerline of the bike !!! ) And once that is sorted you mesure up the spacers you need to fill in the gaps and get them done Offset sprocket like @george 1100mentioned, it should need 5mm if i remember right ?

-

-

Slingshot 1100 RS38's setting might help out some

Joseph replied to alfiestorm's topic in Oil Cooled

Thats a good tip. I have give or take an equivalent setup. What did the dyno say ? -

GSXR 750 W Rear Solo Seat Fairing

Joseph replied to Muddy's topic in Water Cooled, V-Twins, Singles and 2-strokes

Relocate the ECU starter relay and especially fuse box (for easy access) to under the seat and get a smaller expansion tank from a 50cc liquid cooler scooter. Most bikes leave the factory with accessibility, ergonomics and ease of maintenance properly addressed during the R&D phase. Can't complain if stuff gets a bit awkward when trying to fit non standard stuff to it -

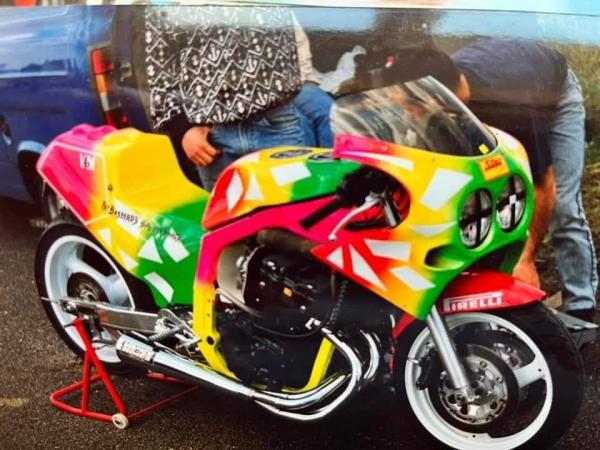

Awesome 2-Stroke Pics

Joseph replied to banoffee's topic in Water Cooled, V-Twins, Singles and 2-strokes

-

-

What about spacing ? OC engines with 36mm carbs have different length inlets also depending on the engine

-

On a standard 1200 you'd probably get good use from the RS34 Isn't the Inazuma carb spacing the same as any other oil cooled engine ? Any rack can therefore fit using the right inlets

-

- 7 replies

-

- 11

-

-

-

Looks more like an aircooled 6 with an oilcooled head