-

Posts

5,454 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

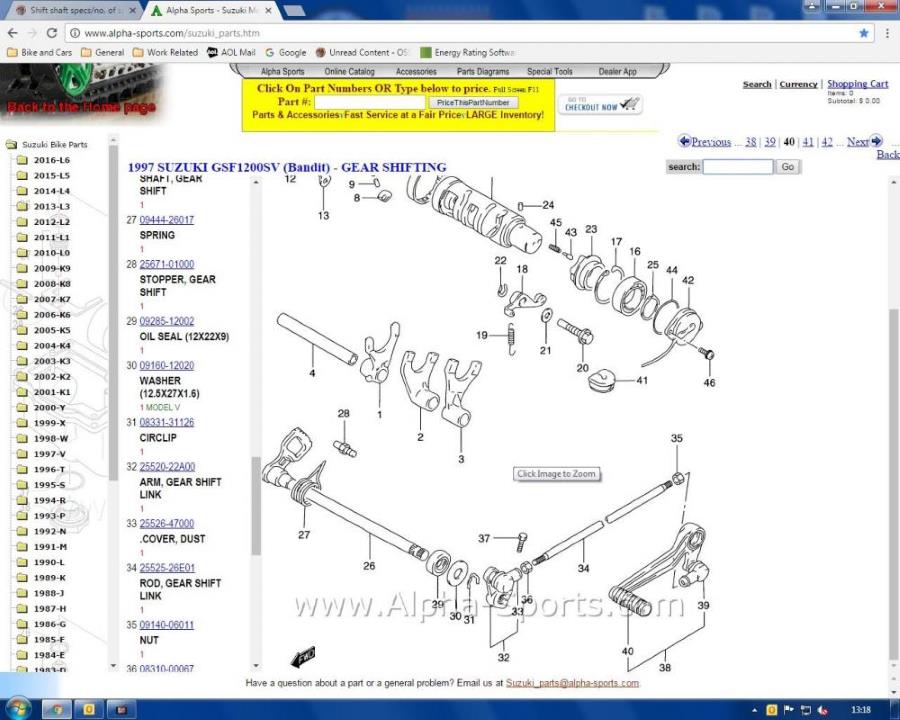

Dunno about the spline count - i've found 'most' bikes have the same number so levers swop......... Guessing part number 32 is what you're looking for?

-

Best start learning or get used to being raped at a stealer! Get a Haynes manual, read it and read it again then try and follow the fault finding diagnosis but if you haven't got at least a good basic toolkit you will be stuffed to fix things but may at least be able to point to the problem at a stealers!

-

I've got an 1100 K/L CDI that I took off when I installed a Dyna 2000 when they first came out. Make me an offer? ( comes with plugs and short cut wires)

-

Nuffin' to say you can't spray it over the core inside the cooler! Or does that have a downside?

-

It'll take a fair bit of force but no reason damage WILL occur........it MIGHT, but that's the risk. Usually 2nd is as worn as 5th so usually get replaced together!

-

Its not theory - its tested 369hp with some to go - it only stopped as the undersized injectors max'd out! You are, lower CR, lower boost, lower octane, lower lambda and lower power. If it suits your application then go with it - i'm not knocking it but if a cut needs stitches, a plaster ain't going to be sufficient! Mine was built to make power, turbo flow is good for potential 450hp , 8 injectors (now with 75% more flow) and an intercooler. If increased AFR's are the cure, why use E85 or Methanol - both have considerably less power potential than petrol even when run rich - its because the octane rating / anti det. properties knock petrol out of the field and you can run as much boost as the engine can tolerate to make power.

-

For me with the level of boost you are aiming, at it will be sufficient with another point down if things get a bit marginal, some may disagree.

-

Generally agree with that apart from 'higher boost requires lower AFR' It doesn't and in fact it can make the situation worse. You are pumping fuel in hoping it will cool the cylinder and prevent detonation but most will be ejected and end up burning in the turbo which in extreme cases take all the tips / edges off the turbine wheel. The only safe way to run big boost is either lower compression or better fuel - end of! My bike got mapped to 1 bar using regular 98 unleaded but to go higher we used 120 octane leaded race fuel - ign. timing was unchanged, CR stayed 9.5:1, AFR remained stable and fueling adjusted against boost via MAP sensor but no detonation. It hurts paying for that fuel, but power costs and how much can you afford?

-

Hope that helps?

-

Busa pistons? They need to be preped for turbo use - all those sharp and thin edges have to be removed / smoothed out or you get what you've experienced - sorry! As above re valve seats - the valve should only seat on one angle - the 45 degree one who's width is cut after the other two to get the correct width. Hard lesson unfortunately.

-

Thinking about things - there is no reason not to use TPS with auto correct to generate your baseline fuel map running NA? The correction numbers should be all over the place till the map gets dialed in. I am aware of people who have autotuned a blown set-up but IMO its too risky especially if boost fueling is on a compensation map as most of those have to be adjusted manually? If the fuel map reverted to RPM / MAP based then you could zero / turn off the compensation map and just rely on one fuel map with auto adjustment.

-

APE used to supply Tsubaki chains - don't know if they still do - good chains, i've never had a problem with them.

-

If 'auto mapping' used MAP corrections why are you using TPS for load on a Turbo bike? You must have MAP for turbo use so why not use it? Just reduce the correction limits to something like +15 / -5 so it never pulls too much fuel out and try it again whilst logging?

-

Read an interesting comment elsewhere - all engines produce a small amount of water and a proportion of this will get into the oil. Running the oil sub 100 deg C won't boil off the water so leading to increased contamination. With water cooled engines oil temps aren't usually much more than water temp but I believe oil / air cooled engines have potentially higher running temps as oil doesn't give up its heat to well. I don't think there are too many bikes where the oil does much more than 5-6,000 miles between changes when oil technology allows it to live well beyond 20k miles so a little overheating can be tolerated IMO.

-

I've got some of those and seem to remember they were about 1.2ohm individually? Are yours wired in series as that might explain your figure - but they'll be getting 6-7v only?

-

Simple question - would you connect 4 Dyna Blue coils (0.7 ohm) to your standard ECU? Because effectively that is what you are doing with COP's. Easiest way is just add a Bosch 2 channel Ign. Amplifier between the coils and ECU and it'll be mint! Any other way is underpowered COP's or potentially overheated / fried ECU.

-

Can't comment on the 'cheating aspect' - see this years Classic TT for that little nugget! But if the 750 barrel casting is thick enough i'd take the 750 liners out, bore the block and install the 1100 liners to retain all the screw lugs and markings. Obviously the bottom edges get shortened and crankcase needs opening out but it would look externally completely 750 stock! I remember Sean @ Big CC did a parts bin hybrid 750 that ended up at 995 - very over square configuration so revved to 13k easily and made good power.

-

That's easily cured by wiring the fuel pump relay via the oil pressure switch. Float bowls retain fuel for starting and pump will kick in after a couple of turns of the crank - especially on an oil boiler. Or just put the fuel pump on a separate switch?

-

That looks much like my Innovate LC-1 - see here.....http://www.innovatemotorsports.com/products/lc1.php Hope this works out better for you, keep us up to date.

-

There is a tool to compress the valve in site enough to pick the shim out but you need to add one back in or the bucket will hit the cam face - not goo. Also run the risk of tool slipping and sending the shim into orbit! Best measure all, take cams out, measure shims - rearrange and buy what you need or find a suzuki dealer with a shim set and ask nicely if you can exchange some at a discount on buying new! Your lucky my M head came with no shims at all - Suzuki price x 16! Ouch! Hope 1.04mm was a typo LOL!

-

You don't know what boost you are likely to be using so an IC may be of no benefit and with IC's - small is not what you want. You want / need as big as physically possible a) to cool efficiently and b) to minimise pressure drop across the core. Sometimes better mixture / ignition control can minimise the need for an IC and unless you are running 1+bar boost for extended periods then it is more an accessory rather than a necessity IMO.

-

Unless it can be corrected by moving it one tooth on the chain - its the wear & manufacturing tolerances stacking up. Its usually the horizontal ones along the head face I used?