-

Posts

8,296 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by clivegto

-

Got some 50mm black nylon bar to remake the bottom frame rail chain protector. Was tricky to pop over the frame but managed it with a little heat, brute force and ignorance.

-

No not a chance of that. But I think these mirrors will suit the bike and after all it is a Turbo Magnum

-

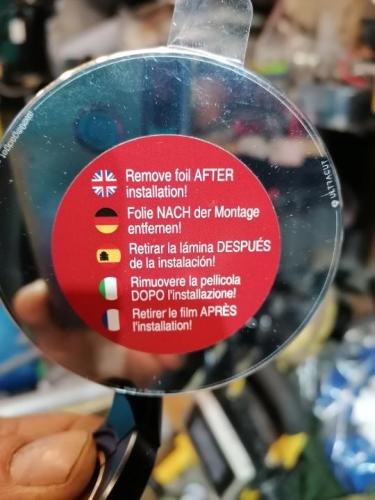

£198.99 delivered no bar end weights there extra, going to make my own. Came from ace custom motorcycles.

-

Went a bit mad the other night and ordered 2 moto gadget mo. View Street mirrors. No glass polished aluminium.

-

Did look at those, cbr one was close as the jmc arm was originally designed for. This one will work fine with a couple more little tweaks as well as been harder wearing. I have a old combine harvester that has ash and oak chain runs believe it or not.

-

Bit more bending with the heat gun some chopping and drilling its starting to look like it will do the job. Still needs a bit trimming near the back frame rails.

-

-

-

-

10mm thick nylon sheet turned up eventually. Cut a 50mm slice of it then started playing around with the heat gun and various quick shift jigs to bend it to shape. Still a bit more work to be done but I recon it will work. If it doesn't I will just bolt some flat bits on top bottom.

-

Gear Indicator for engines that didn't have that feature stock

clivegto replied to Neveragain55's topic in Oil Cooled

-

I run 14mm id pipe to one way valve to 8mm id pipe then to facet pump mounted under the sump then returning into the top crank case.

-

Old Spondon Arm for Slabside 1100 ....will it fit 750F ?

clivegto replied to Moriwaki1105's topic in Oil Cooled

Use the 750 linkage. -

Facet oil pump one way valve, start oil pump before starting engine you will hear it clear its self.

-

As Tony says bottom end can be split with out removing the top end so you best take it to bits for a look see yourself, I would.

-

Sprocket bearing possibley. Usually it's 2nd and 5th that goes on the dogs.

-

That's a good point but aparantly fitting later K5 1000 to the early models is a good upgrade or after market items.but this yoshimura K2 1000 system would need a little bit more modification to fit a oil boiler.

-

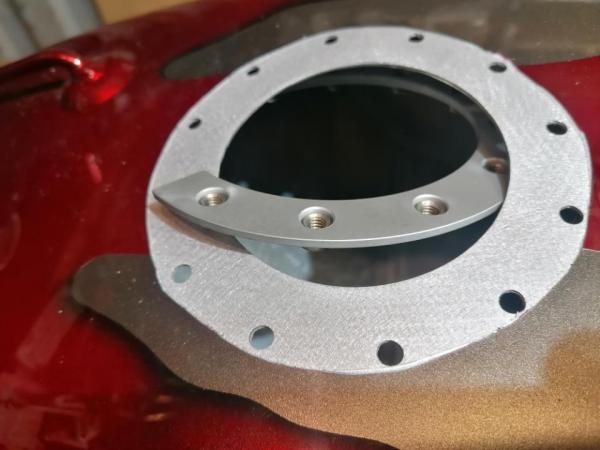

Fitted the fuel return & tractor petrol tap to the tank. Also fitted the fuel cap, had to put a slit in the retaining ring to get it inside the tank. It has a Cork seal which is smothered in blue hylomar, also there is no paint round the bolt holes to stop petrol weeping under the paint.

-

Never seen any dyno figures of before and afterwards with them so who knows.

-

Possibly but I picked a set of K2 headers up for £25 + they weight nearly nothing.

-

-

Don't know, a turbo rebuild shop made my hybrid one up for me after talking to him about the type of power and performance I wanted for my Harris build.

-

Caliper spacors that came with my hel calipers I used to space the yam calipers out on the K5 forks were narrower than the mounting points which looked odd to me. So I ordered some 25mm billet bar to make some up myself on my little lathe. Looks much better now I think.

-

Could you put the old bearing shell back in then cut the bar out you welded in and weld another bar in at 90° to the first one to push the overall headstock round again. Just a thought.