All Activity

- Today

-

ColinH started following turbo/EFI setup

-

This thread is super useful to somebody new to bike builds like myself. I do some automation in my day job and wondered if anyone had built a control unit from a PLC. Some of the units are now low voltage and very compact. PID loops and other controls are common and high switching speeds with solid state now. Maybe this is complete madness but it wouldn’t be my first stupid idea

-

It’s more the fact that APE say they are finished to size, which these aren’t. I’m not saying they are no good, just that different to description. I like to do as much as I can myself, maybe that’s frowned upon? Maybe I’m coming across as know it all but that’s far from the case. I do machine parts to tight tolerance but engine machining is new so trying to understand norms. If I do ream them myself I will blue up and take a print to see if alignment maintained. The other option is to machine a reamer guide engaged with seat taper.

-

Whilst most of us don't give a toss about undersized guides as it's the head or engine builders responsibility to re-size! Plus Suzuki San only has to fit his valves whilst APE have to allow for any OEM & aftermarket offerings! I trust you have seat cutting gear as new guides need seats recutting - just saying!

-

Builtwithpurehate joined the community

-

Pistons and guides arrived today, dropping cylinder block off to machine shop tomorrow. valve guides are supposed to be finished to size but 0.1mm under size. I know they will probably need reaming once installed but that amount needs a bit more alignment that taking out deformation. The genuine Suzuki guide is correct but these are well under. Shop reckons a couple of weeks to bore cylinders so gives me time to build head and start ripping other bits off bike.

-

Before I installed my 150psi fuel pressure sensor , I set the base pressure with the liquid filled gauge I had on the fuel rail. This was obviously not accurate.

-

Fortunately or unfortunately its got Termignoni pipework with an akra can, it goes have 38mm carbs and a stage 3 done many years ago by Craig.

-

probably because of the high presure. If you run the pump at 90psi it flows around 225L/Hr according to various people who bothered to do the test. https://www.google.com/search?sca_esv=04ccc06d6a14a3bd&rlz=1C1CHBD_nlNL1043NL1043&q=bosch+044+pressure+graph&udm=2&fbs=AEQNm0Aa4sjWe7Rqy32pFwRj0UkWd8nbOJfsBGGB5IQQO6L3J_TJ4YMS4eRay1mUcjRHkZxg8Vy0p2Xq9PcZNNq1Ew9zQooLZH5gQS3wVxeld5ohRXutwtU5CU2X36_uLH1pIUk5kgTFJ72LHrHs1dTrQZP2bShAIpXPbBXJuSHMpD67_7PI_IrPeKYP6OPe9Ff2p8rktfex&sa=X&ved=2ahUKEwim-rbVnLmJAxVygf0HHe-QCCcQtKgLegQIDhAB&biw=2560&bih=1319&dpr=1#vhid=SGOLBMIevLm8wM&vssid=mosaic So if you go north of 400hp I can imagine this will become an issue.

-

A friend with a 3576 on e85 had to go with mechanical pump after 641hp. I run 2 batteries, won't be a problem. I'll set up the ecu so the second pump kick in at 30psi. M.

-

Well your on the right track Craig recon,s the Akra is the best pipe

-

Read your first post back, you mention pressure

- Yesterday

-

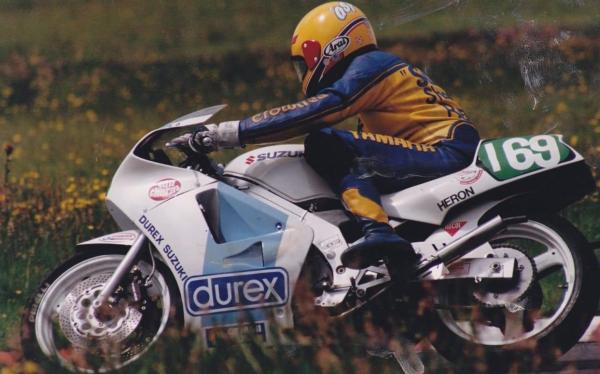

Awesome 2-Stroke Pics

Wee Man replied to banoffee's topic in Water Cooled, V-Twins, Singles and 2-strokes

-

Yeah that phat rear hoop looks ace!

-

It's got that 'look' !!

-

yeah Japanese cruisers (Anal intruders and Viagras and shit) have 1" handlebars.

-

Just checked, and it looks like Suzuki uses the same clutch MC on their metric cruisers.

-

What size turbo has he fitted ?

-

I have now ordered the MTC 10:1 pistons so rebore to 81mm is next on the cards. I had considered doing this myself on mill which boring is no problem as I have to hold tighter tolerance on lots of other work, it's the honing knowledge that makes or breaks it so better to put them out than wreck new rings or worse. I did consider removing the cylinder sleeves, boring them in lathe etc but they won't be same shape once reassembled (Been there with lose tolerance bearing bores in past). Suzuki Performance Spares were really helpful and also split a pack of APE valve guides for me so buying 8 seemed like better value than making them. I will measure volumes once all done and see if I end up machining some extra space onto of pistons for compression ratio. SPS did say they often turn out closer to 9:1 on most installs he has done so will see. I don't mind 9:1 as I will be running intercooler and also EFI / Ignition control which should lower risk of detonation, if done correctly. Hopefully get head built this weekend. I have done a little work on ports, nothing more than blending the huge step between valve seat and port on inlets. Check cams, journals and other bits before assembly.

-

- 129 replies

-

- 11

-

-

Any updates? What is the weight and power? Are you running a total loss?

-

Lovely work @clivegtoShe's gonna be a cracker!

-

And fat heads ??

-

I had an old k, done by Roger upperton and Craig Taylor at dynotorque, and it was an animal, so looking to do similiar with this one. Top end refresh, possibly forged pistons, gas flow, lightened and balanced crank, shells looked over etc. chassis wise, ohlins rear shock, 750 swing arm, lighter wheels, bigger brakes and new brembo corsa corta master cylinders… also go my hands on a brand new tank from france, so all paintwork will be refreshed. not sure whether to powdercoat the frame black or leave it polished…