94RF1146

Members-

Posts

66 -

Joined

-

Last visited

Reputation

87 ExcellentPersonal Information

-

Location

Vancouver, Canada

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I wouldn't worry too much about piston speed. Our 200-300g piston is nothing compare to those promod piston combo... https://rehermorrison.com/tech-talk-80-getting-to-know-nitrous/ Cheers, MM

-

Here's mine , lots of grinding and 40 thou shaved from the on rod bolts to fit 65mm crank & Carillo rods.

-

-

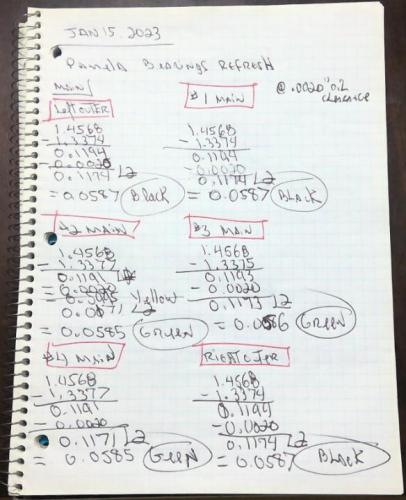

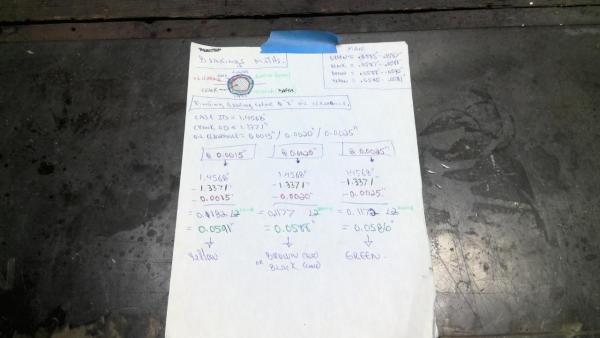

Front & rear wheel bearings done. Next is stem bearing this weekend. Rod & main bearings later. 2 thou on the mains & 2.5 thou on the rods. 20/50 oil with zzdp. Here's my tech sheet with example for 3 different oil clearance. That's how I do it. If that can help someone... Cheers. M.

-

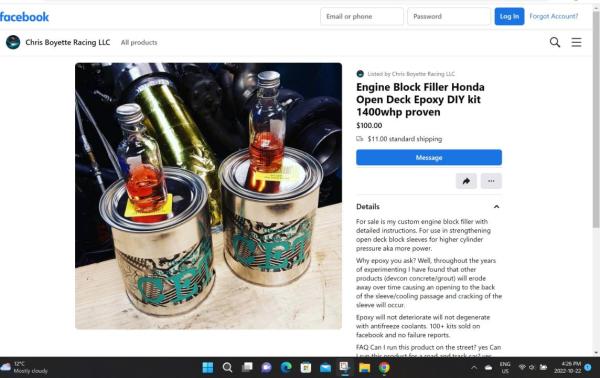

Winter project... The watercooled 79.5mm piston kit is well known for not holding water in NA form, imagine under 30+ lbs of boost. So I decided to go with a Mallory 110gph pump I had. I'm doing mockups with a hurt head that dropped a valve in 2010. The plan is too keep the head and block deck dry while remaining them watercooled. I use baking soda as a filler and will use Chris Boyette expoxy kit that the Gurls blouse car guys are using. Coming in from the water pump to the factory coolant ports in the front of the block > out the back of the block to the side of the cylinder head using -8 fittings > out back of the head factory coolant port > radiator cap / CLT sensor > radiator in tail > out radiator back to water pump. Guys in Outlaws back in the days were going all dry or keeping water in the head. I don't like the heat generated by the dry block. Keeping both in my project. I'll post pics when the motor is on the motor stand later. M.

-

-

Yes but not really necessary. It can circulate by convection. !/4 mile bike.

-

I decided to removed the water pump and block it off with a brass freeze plug. That way oil & coolant will never contaminate each other. Awaiting for the freeze plug. M.

-

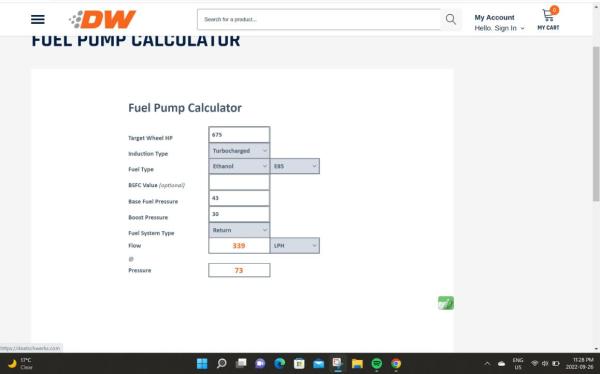

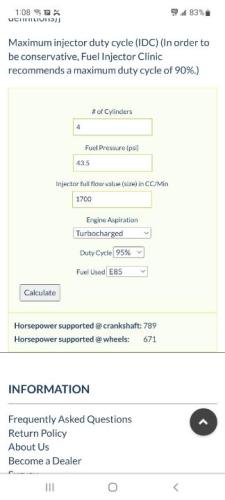

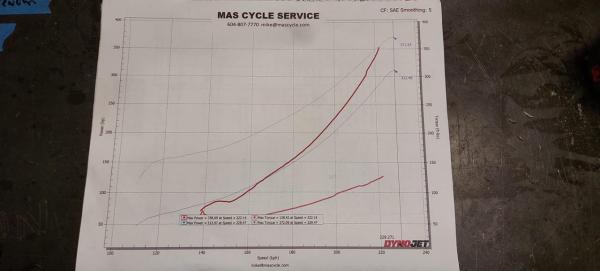

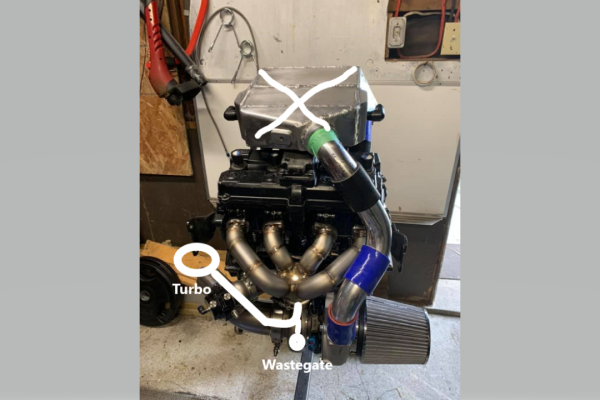

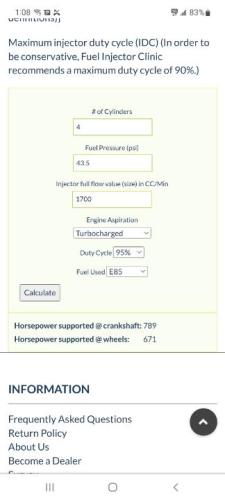

Now having water pump issues. Shaft is bad and seals are busted. I was getting coolant(water) in the oil and leaking out water at the pump. Awaiting a friend for his water pump and ordered parts to rebuild mine. My 400 LPH fuel pump support 340 LPH @ 30 psi... Last dyno graph when I spit #2 spark plug. 30 psi boost cut. recorded 37 psi. Guess what, peak torque x rpm (9500) / 5252 = food for thought... Off season scope: - Water pump issues - Relocate wastegate / turbo / up-pipe - Swap 4 inputs - Head steam bearing replacement - Extend wheelbase 4" - Learn Maxx ECU - Testing & clutch setups

-

Update... I replaced the head gasket, removed all the coolant and associate components. Now dry block. Also installed a scavenge pump. My oil level was just 3/4 below the turbo centerline. Had oil in the exhaust. Problem fixed (temporarily for one more race). Got idea for boost creep problem... A 90* + a 45* pipe and associate V-band (3). M

-

Yes, I'll look into it. Replaced the plugs and changed the oil. Went to the track again but didn't run. Got the symptoms of blown head gasket. White puff at start-up and sweet smell. No big deal, season is over. I'll replace it, copper coat it and go dry block. No more issues. It doesn't stress me out at all. M

-

Hi 1460, I found the plug sitting on top of the motor like that !It just popped up under boost. The threads were still in the head and I was happy to see that the grounding strap was still there. I removed it using a flat blade. In couple hours I'll put CR9E I have, open the clutch pack and look at plates, put oil in it and start her up. My fuel system can support 600+ hp. My Garrett GTX3576R Gen 2 can support 750 hp. The clutch is my weakest point. There's nothing out there for watercooled GSXR-1100 motor.

-

Arttu, the best we got was 387 hp. The dyno speed wasn't matching the gearing. I'll put longer bolts and more weight.

-

Hi guys, Went to the dyno today... I set up the boost cut at 30 psi and saw 37.1 psi right after the boost cut. Then, something was wrong, strange noises and aborted the pull. Thought we had grenade the clutch basket but after investigation discovered that I was running on 3 cylinder. The clutch can't hold power with 5 washers on the arms. Had synthetic oil in the bike, I normally use Lucas 20/50 dyno oil. Air gap stayed the same at .120". Installing longer bolts and adding more weights for next dyno. Here's couple pics: