-

Posts

613 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by george 1100

-

It's possible. Also maybe cam timing is out. Did you use slotted cam sprockets? Bolts may have worked loose. Bent rod or rods maybe. Piston may have smacked the head Was it there from day one or did it gradually appear or suddenly appear. How was it performing? I'd be taking the valve cover off for a looksee and checking comp as a starting point

-

Yep, doesn't look right. From what I know, that should not be able to protrude like that unless the orifice has been drilled out

-

I'm in Aus so price probably not relevant to you. Also had other machining work bundled in so not sure of the price breakdown per item. I bought the sleeves from APE. In short, motor has oversized valves, 40mm tmr's and yosh-2 cams. Power is 'impressive' and usable throughout the rev range

-

I have a 1277. There's a big cost to consider because of the sleeves and boring the cases

-

I know of a guy that successfully ran 85mm pistons in a 1127 block with LA sleeves

-

That dent would need welding and then resurfacing....again

- 9 replies

-

- 1

-

-

- gsx-r 1100

- slabby

-

(and 2 more)

Tagged with:

-

You would need to check valve to piston clearance also

- 9 replies

-

- gsx-r 1100

- slabby

-

(and 2 more)

Tagged with:

-

Test the petcock

-

Sounds like a fuel issue

-

Haha, this is getting weird but I'll play along I don't know about other gaskets, I'm just talking about cometic multi layered steel (MLS) gaskets. Zoom in and you will see the rivets that hold the multi layers together

-

The 3 layers are held together with rivets. Seperate the layers, super clean them, use copper spray as per directions, re-rivet

-

I run 750 springs in one of my engines with oversized valves, oem retainers and 9.2mm lift intake cams

-

That's good to know, cheers. Out of curiosity, why did the rf's have a pump fitted?

-

He runs race fuel also which may affect how much capacity that's required. So would a 3-5 psi 30 gallon/hr pump together with a regulator that operates in the 1-2 psi range with a return line, do it?

-

Motor is apparently full house 1340 putting out 180hp+ I've been researching for him as curiosity got the better of me. Holley have some interesting products that are 2-4 psi and flow 30 gallons/hr . Have low pressure adjustable regulators also Yes Joseph, will need a return line

-

Yes I was thinking this but wouldn't a turbo bike require more psi as the bowls are pressurised. I'm no turbo expert by the way. Out of curiosity, what psi pump and reg are you using?

-

Has anyone ever done this? I'm asking on behalf of someone that's has a 1340 race car and the tank sits lower that the float bowls. They're currently running a vacuum activated pulse pump but it's not coping

-

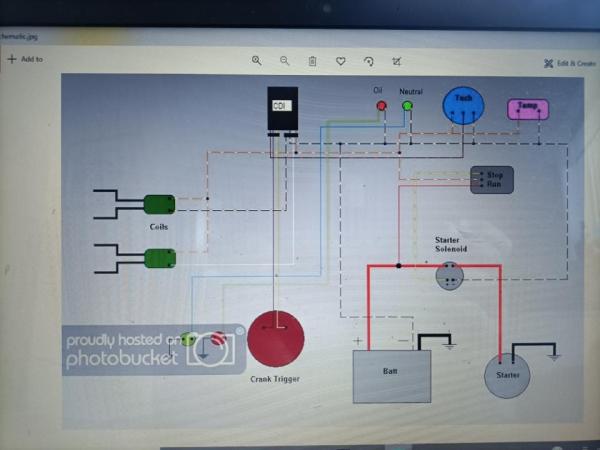

Doesn't show tacho, neutral and oil pressure sensor

-

This is with no alternator. Can I ask, why the alternator for drag/sprint? Can just charge inbetween sessions

-

Nice bits

-

Sounds like your bolt is loose. I had a similar issue a while back. Probably wasn't torqued sufficiently or correctly or both

-

The MLS ones can be pulled apart by removing rivets, cleaned, light copper spray, rivet back together and off you go

-

Why don't you ditch it and run total loss. Saves 5kg also