-

Posts

2,249 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by jonny1bump

-

-

I use impact gun too. If your talking M clutch and undoing big nut that holds the conical springs against pressure plate, then get two pieces of decent steel. Join together one end with long bolt into swing arm pivot and at oposite ends bolt in each arm that lines up with the slots in the outer pressure plate. Hope that makes sense, can take picture tomorrow night if you don't understand that ramble. If you on about inner basket so clutch already out long bar attached to old clutch steels with spacers.

-

The stock limiter cut out is 10500. Red line of 11 on Suzuki tach is about 10200 in reality if I remember correctly. I've been revving mine to 11k for years and years at prolonged rpm and to be fair on a balanced and reworked crank that's been fine for me but certainly no more. But saying that on this latest rebuild have reduced it back to 10500 and see how curve looks next time it's on dyno before changing anything. I certainly would stick to 10500 on stock crank.

-

Yes heavily reworked, but to be fair it had a real hard life.

-

It's a skool night too.

-

New pistons need cc calculation 750 slingshot

jonny1bump replied to Wcrracing221's topic in Oil Cooled

Totally agree I really don't give advice on specs. -

Wraith have you been drinking

-

To replace the rear tensioner guide you go need to split the cases it's attached to hollow dowel which has two rubbers pushing on said dowel. You can see it in this picture rear of crankshaft in centre.

-

Peeps who had them pop very few reset after an incident.

-

They listening to you the Rene.

-

Then read the article here link.

-

Click on Oil cooler wiring mods.

-

The circuit breaker. It's all here.

-

Get some pics up dude, we all like pics.

-

Actually re thinking that you end up having to use two taps, stupid idea cancel that. Did make own adaptor and linked with high quality washing machine style tap did leak eventually through tap pivot and was bit ugly if honest so went back to pingle.

-

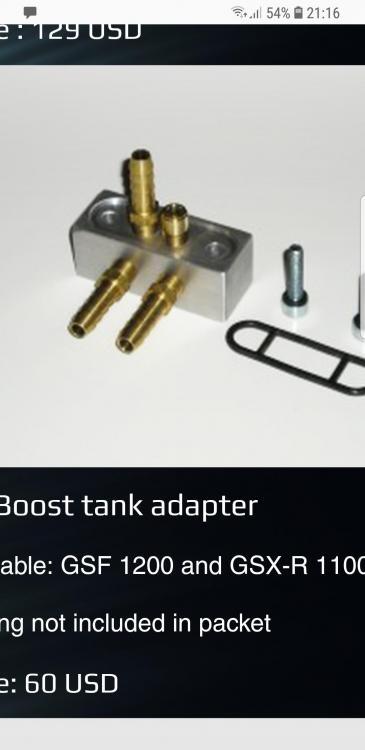

Or as turbo boys and I've done in past make own adaptor. Or buy one these using the remote tap and dry connects.

-

Rf 900 that interesting. You could use mod tank adapter, cut the normal on position long pipe to same height as reserve pipe and use two dry connect fitting get high flow two feeds.

-

Does not hurt to use little thread lock too.

-

Clive first option carbide drill with great care very brittle and expensive if it snaps inside new drilled hole big trouble so only on pillar drill or mill. Failing that spark erosion, vendor job then.

-

My crank snapped at 11K

-

Oil coolers: branded v generic. Is the extra cost justified?

jonny1bump replied to Dezza's topic in Oil Cooled

For cooling efficiency cannot beat curved proved by radtec when they did work for Triumph. Just adding my 10 pence. Not saying anything wrong with items shown here before someone gets on there highly strung high horse. -

Before you spend on repair kit make sure they not oval as quality really not the best. Every time I've used repair kits they improve slightly, all can say really

-

If it's devil they good headers 4 into 2 into 1 gives stomping midrange. I only went akro when it shook itself apart.

-

Awesome result congrats indeed.