-

Posts

2,249 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by jonny1bump

-

Once you have machined pistons for correct compression there has not been a huge amount of ally to go carving I have found. Ok depending on pistons your looking at, I'm specifically looking at the 13.1 pistons.

-

Aftermarket been heavier makes sense, why they more robust. I bet the 13.1 JE's give far more compression then that.

-

That really fun Rob you must proper got under his skin and wound him up, sounds like he proper lost it.

-

That's bit harsh Rob why he say that. You Normally find those that slag others off diverting attention from themselves for been useless.

-

I'm not sure what sort of emergency would require keeping old gasket for spare, only one place that's fit for.

-

-

Absolutely change gasket for new one. Are pins discoloured or marked in anyway if not gentle scotch bright pin and piston so they rotate nice and free. Do not touch little end area appart from checking for play. Good idea to replace pin circlips thou.

-

Making sure everything lines up, is smooth free, etc. Inspect everything and little gentle nibbling away with die grinder making sure everything lines up nice. The shims take while to make very fiddly.

-

First job as said sprocket off, then drop sump off and clutch out see if can see anything broken, as you said may be simple. I'd rather fix what you have you know it's good then, barrels head etc can be left untouched.

-

What ever cams you use check the thrust faces are the same. When I converted my M head to screw and lock nut I had to get head welded then I re machined. Also check lift so coil bind of the springs and make they don't bottom out on the guide. This really not answered your question really but hopefully tells you what to check.

-

SRAD 750 Fi to carbs?

jonny1bump replied to Motovalet's topic in Water Cooled, V-Twins, Singles and 2-strokes

There are some on the bay for £24 each. -

Let us all know what you find.

-

Or below now.

-

Read gearbox thread above. Sounds terminal. First point call sump off and clutch out see if can see anything, whilst still in bike. You know it's got to come apart but you still check basics and hope for devine intervention. Basically engine out split cases can leave head and barrels on.

-

Check out the carb mod above see if you have step in the slides.

-

I had my rockers hard welded. Oops gone off topic. Right can really see the benefit of this on gear teeth but my gut feeling really dubious if it will help with dog wear. Not convinced.

-

Lads all interesting stuff indeed.

-

I know good words indeed can't fault them.

-

No worries glad to help.

-

That's funny.

-

Whose doing that Clive and what they do sounds very interesting.

-

I'm starting to think Suzuki did the sloppy tolerating on purpose to allow for build variation and they are relying on the undercut dogs to pull themselves into place. But it's all about that whole blue printing thing getting everything as good as it can be. Also not mention selectors pawls these should be smooth most rebuilds end up stoning these. Also selector forks, any damage and burning bin them simple. After having box lock myself and seeing shafts snap it needs to be right don't be cheap.

-

Disclaimer - If you follow this modification it is completely at your own risk and no one other than yourself can be held accountable for any mistakes, actions or accidents which could occur from any implemented modifications and from riding in an unsafe or dangerous manner.

-

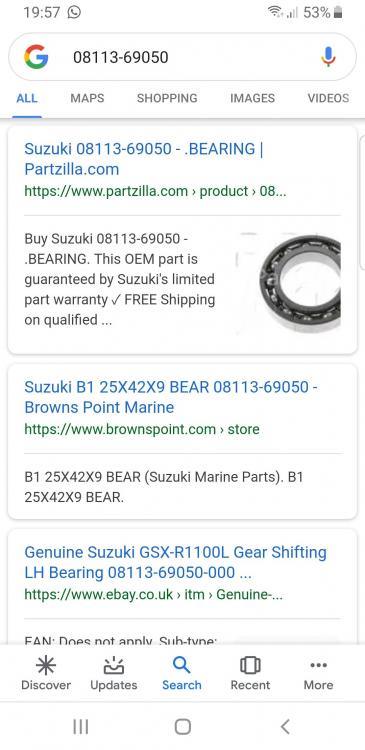

There is quite bit play with 16 in housing you need to check dog alignment to check which side you shim it. May have to do both sides. You may need to shim behind 25 too everyone is different. I got flat piece shim steel of various thicknesses and almost make round washer the same size of outer race only ( for 16 for 25 then vice versa inner only but not so important) They quite difficult to make. Good start sandwich between wood drill hole with carbide or diamond tip hole saw, tin snip outer diameter and gentle grind and spike bits with fine grinding wheel been very careful not to ruin your fingers. Mock build it and you see it move back and forth. You got to be really careful that you basically don't f**k it up and jam mechanism or push dog engagement to one side, that would be a bad day first time you do flat stick change. Also don't make shim too big and stop oil getting to bearing. I thought long and hard if I was going to post this information. If you not an expert building stuff don't do it. Talking about good quality oil with regular changes also will help gearbox not just engine. I use the expensive Motul and change 1000 to 1500 miles max. But not starting oil debate please that's been done many times and everyone got preference.