colinworth79

Members-

Posts

942 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by colinworth79

-

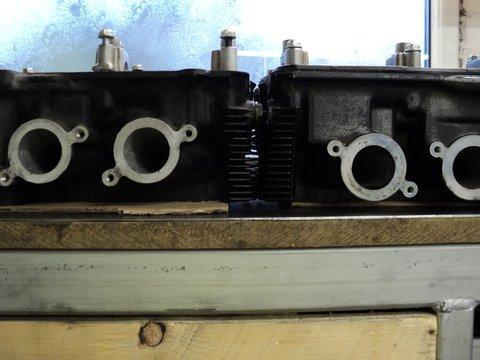

I would say the dot head has better inlet ports as well as raising the compression. If doing a big bore conversion you can normally spec the compression you want . Pic of 750L slingshot frame bandit 12 motor and carbs with dot head .

-

If your using the bandit cdi box then yes a resistor of 100 ohms .

-

Ape block bored to 85mm and the crankcases opened up. What have people done about the oil feed on the 2 sides of the block ? Have they been left as stock or been blocked off with a grub screw ?

-

think Mr upperton is well respected in doin oil cooled heads . I had a bandit one mildly ported back in 2003 by TTS which I have used since and not had any need to touch .

-

the 750 head had a smoother radius nearer the bottom of the inlet valves . No idea how much better it flowed or the power increase you expect with back to back tests between a 750 and 1100 head tho.

-

-

bandit and 1100 head design basic the same . 750 j/k head has smaller combustion chamber raising compression up 1 and raised inlet ports . 750 j/k cams or 1100 k/l cams lumpier than bandit . 1100m head totally different design with shims / 16 cam lobes

-

looks like micron .

-

quite a few bikes had 17 front and 18 rear . Just be careful on tyre choice as its the overall diameter that's important .

-

As anyone got a list of the bolt lengths that hold the 2 crankcase half's together . The m6 ones around the gearbox area . Have a pair of bare cases and got ape main studs for the front half. Gsxr 1127. Thanks Colin

-

you need the 1127 outer basket due to the amount of teeth on the drive gear . Think k7 750 you have to swap the drive gear for the original ?

-

I thought a bandit gearbox was basically the same as the later gsxr with undercut dogs and the wider output bearing . If the clutch is well worn and your thinking of the engine running more power than standard then may be good idea to upgrade to a gsxr clutch . I wouldn't have thought the steel plates were worn , I've managed to wear out loads of friction plates but not the steel ones .

-

I would remove the carbs , then do a compression test using one that screws into the plug hole not a push on one . Think they should be roughly the same . If its low on a cylinder it can only be valves or you have broke a ring putting it back together. If its low on say 1 and 2 I would say head gasket. Not really good practice to re-use a head gasket especially multi layer steel one but i have once in an emergency and didn't have a problem .

-

your clutch is dragging . Make sure the lock up plate is spaced far enough away from the pressure plate to allow full lift . Take the clutch cover off and pull the clutch lever in should be a small gap between the pressure plate and the lock up plate with the arms on . I had to shim mine out slightly to stop it dragging .

-

sweary bob you have an original spondon bandit then , very nice . I know of 2 others . Only 5 built . My Gia framed one as I couldn't find an original . Gav has only built the one so far .

-

Each to there own but been running second hand busa pistons in mine for 8 years now with 15 psi . Has enough go to lift the front wheel by pulling the throttle to the stop in 4th @150mph . I have spent a huge amount of time setting the fueling up tho . If its not set up right pistons are not going to last long even if they are nice shiny new forged ones . Also try the stock bandit clutch but I couldn't get it to stop slipping when my bike was running a 1246 kit and cams let alone a turbo .

-

Hello Phil , a speedo from any slingshot should fit J to M model . 1100 Speedo will fit also but will read upto 190 instead of the 750's 160mph if your worried about keeping it original . I've not experienced a problem with the speedo head its self but have found the tags on the drive which locate in the wheel to break off or get bent . Cables do break as well .

-

bike was given a full service before I started using it to commute. Plugs , oil , air filter ect . Revs only start to hang up when its stop start traffic for a few minutes. Odd that if you snap the throttle open quick it then cures it . Only thing I need to do is to balance the carbs hopefully next week end .

-

Not had a problem like this before and wondered if anyone has come across this - bike gsxr 750L totally stock uk bike . 19000 miles from new. When the bike is ridden in traffic as it gets hotter the engine revs will start to creep up by them selves up to about 3k but if you blip the throttle quite hard they will then return to where its been set 1500. Same thing will happen when you pull up at the next set of lights . I had the carbs off when I first got it and removed the float bowl and cleaned them out (stock jets) and there is a new genuine Suzuki throttle cable fitted couple of weeks back . I'm thinking maybe slide sticking or a split in one of the rubbers onto of the slide maybe ?

-

I always find when I have trouble with the clutch on my bandit best to strip the slave cylinder off, take the piston out and give everything a good clean . Then rebuild it and spend some time bleeding the system so all the airs out . Normally sorts the problem . Bandit clutches are the weak point of the motor when you start to tune them .

-

stripped the turbo bandit down after a little miss hap as I'm running an aftermarket frame interested in the weight saving . Has anyone a stock frame they could stick on the bathroom scales for me ? My frame is 13.4 kg. thanks colin

-

Got a 750 as a project , plan is to leave it looking standard then transfer over the turbo 1216 lump from the bandit . I'm hoping to purchase a 1100 cdi box and plug into the stock loom to lower the rev limit , are all the slingshot cdi boxes the same ? If not which do I need . Bike 750 L 1990 .

-

if you have put 12v straight to the starter then starter motor would be suspect , I would have thought even with poor earth and leads it would try to do something .

-

if it was mine ,get a meter one lead on the positive of starter and the other on the engine somewhere where its clean and no paint . Ignition on and press starter button see what you have voltage . If no go check solenoid is operating by hearing it click . If solenoid is working disconnect both large wires and connect meter wires to the two terminals and set meter on ohms see what reading is hopefully zero . I would say from the above the solenoid contacts are getting worn and sometimes there is high resistance . To double check ignition on and pair of pliers across the two large terminals to short out . If solenoid is not working side stand switch ,start button problem