-

Posts

5,755 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Trikes still need forks! What about adapting some MX forks - plenty length there.....and strong!

-

But you've got a 90 bend on there into a fabricated 180 bend ! If you'd loosened the compressor housing and rotated it back 30 odd degrees the outlet would have only needed a 45 degree link pipe into the cooler bottom? Straight was the wrong word - direct - would have been better.

-

I realise you are doing the fabbing but if you have a boost pipe from cooler to plenum on the left - it could have been routed on the right to achieve the diagonal flow split. Also I like simplicity so why the ugly lower pipe connection from the turbo - straight in the bottom is nice and direct and an angle plate in the end tank could have pushed the air across the core? This isn't a criticism just points for mk2 version LOL!

-

Which is why they've sort of fallen out of favour with the 'faster' boys - scavenged dry sump systems are more reliable and allow the bike to be lowered more. Having seen a few of the swinging arms - they are difficult to engineer, retaining the friction free movement and keeping air tight for suction - fried clutch does them in a treat!

-

The advantage using brass or copper nuts with stainless or steel studs is they don't gall and can't be over-tightened but I have used normal stainless with coppaslip to avoid seizure equally successfully.

-

I doubt it, as why would you have a hose clamp end, if it screwed into a rail? The thread is std. metric and clamps the reg to a bracket where ever you want it.

-

Yes but the CDI's also have different plugs / wiring so can't just plug one to the other! Thought the pick-ups were virtually the same only rotor different?

-

Different CDI and Ignition switch.

-

Not a fan! Lot of pipe will lose heat energy = less to spin turbo. Look like std. dia. pipe? Smaller than usual helps gas speed. You asked! LOL

-

I would have thought a couple of tacks back and front would suffice - its the friction fit that stops it going anywhere. A cold chisel would break the tacks if ever needed?

-

Garrett GT2560R will do a bit more than that but less boost = cooler charge!

-

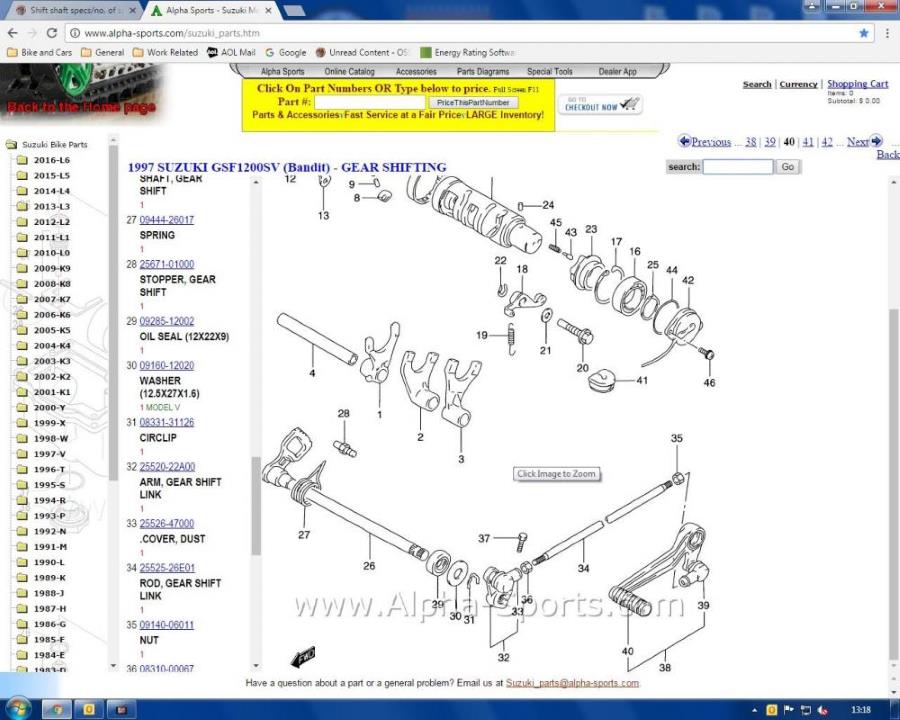

Dunno about the spline count - i've found 'most' bikes have the same number so levers swop......... Guessing part number 32 is what you're looking for?

-

Best start learning or get used to being raped at a stealer! Get a Haynes manual, read it and read it again then try and follow the fault finding diagnosis but if you haven't got at least a good basic toolkit you will be stuffed to fix things but may at least be able to point to the problem at a stealers!

-

I've got an 1100 K/L CDI that I took off when I installed a Dyna 2000 when they first came out. Make me an offer? ( comes with plugs and short cut wires)

-

Nuffin' to say you can't spray it over the core inside the cooler! Or does that have a downside?

-

It'll take a fair bit of force but no reason damage WILL occur........it MIGHT, but that's the risk. Usually 2nd is as worn as 5th so usually get replaced together!

-

Its not theory - its tested 369hp with some to go - it only stopped as the undersized injectors max'd out! You are, lower CR, lower boost, lower octane, lower lambda and lower power. If it suits your application then go with it - i'm not knocking it but if a cut needs stitches, a plaster ain't going to be sufficient! Mine was built to make power, turbo flow is good for potential 450hp , 8 injectors (now with 75% more flow) and an intercooler. If increased AFR's are the cure, why use E85 or Methanol - both have considerably less power potential than petrol even when run rich - its because the octane rating / anti det. properties knock petrol out of the field and you can run as much boost as the engine can tolerate to make power.

-

For me with the level of boost you are aiming, at it will be sufficient with another point down if things get a bit marginal, some may disagree.

-

Generally agree with that apart from 'higher boost requires lower AFR' It doesn't and in fact it can make the situation worse. You are pumping fuel in hoping it will cool the cylinder and prevent detonation but most will be ejected and end up burning in the turbo which in extreme cases take all the tips / edges off the turbine wheel. The only safe way to run big boost is either lower compression or better fuel - end of! My bike got mapped to 1 bar using regular 98 unleaded but to go higher we used 120 octane leaded race fuel - ign. timing was unchanged, CR stayed 9.5:1, AFR remained stable and fueling adjusted against boost via MAP sensor but no detonation. It hurts paying for that fuel, but power costs and how much can you afford?

-

Hope that helps?

-

Busa pistons? They need to be preped for turbo use - all those sharp and thin edges have to be removed / smoothed out or you get what you've experienced - sorry! As above re valve seats - the valve should only seat on one angle - the 45 degree one who's width is cut after the other two to get the correct width. Hard lesson unfortunately.

-

Thinking about things - there is no reason not to use TPS with auto correct to generate your baseline fuel map running NA? The correction numbers should be all over the place till the map gets dialed in. I am aware of people who have autotuned a blown set-up but IMO its too risky especially if boost fueling is on a compensation map as most of those have to be adjusted manually? If the fuel map reverted to RPM / MAP based then you could zero / turn off the compensation map and just rely on one fuel map with auto adjustment.