-

Posts

5,448 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Gixer1460

-

Or even this one ...... https://innovatemotorsports.com/support/manual/LC-1_Manual.pdf It's the same one I have for my car but without the gauge - got a whole kit but the switch / LED bit is daftly easy to do.

-

Well i've blown the manifold off a few engines whilst using dodgy ignition kill with an air shifter on turbo motors, and seeing as a lot of people bolt the manifold to the head, you lose that potential pressure release. Nitrous assist is always good for a spectacular backfire. Anyway it's all info for the masses.

-

Thanks for the circuit diagram which I sort of followed, although some of the component symbols are beyond me and none of the components were listed in my freebie PCB designer software so got a bit stuck ! You may have another sale here - even a kit of parts would be good - metal gluing is easy, and satisfying!

-

That's an interesting comment re: backfires. If anyone has had a mooch around a Top Fuel bike or car they tend to have sacrificial burst panels built into the manifold to protect the blower essentially. The one on Ian King's bike was a 2" / 50mm dia disc of what looked like tin foil that held 40 - 50psi boost but a backfire would rip it to shreds and release boost pressure safely.

-

True - but when does it become out of tolerance ? If you are anywhere in the south / south coast - I'd recommend Turbo Dynamics in Christchurch - always done good work and come up with solutions to my requests - I used to spend between £200 - 250 each time including full strip, rebuild and balance, labour and parts. Even when swapping parts, the old bits had value so it's not like having to buy a whole new compressor say.

-

No arguments please but he does have a point - look at the tacked joints inside - there is no penetration from the outside finish welds, likewise the top closing weld on the far edge - maybe 0.5mm deep (visual guess) - I'd say not if, but when, for weld fracture.

-

I believe there is possibly a mix up between centre to centre measurements and edge to edge measurements? All air and oil cooled suzukis have had 77 - 93 - 77 ctr. to ctr. carb. bores forever. Dunno what the water boilers ended up as?

-

If the fuel supply is higher than the carbs then the float bowls will always fill by gravity!

-

I hate vernier calipers - I was using the end of the slide - not where the '0' was ! DOH! Long live Digital Calipers for Idiots - like me LOL!

-

Hmmmm! I understand the PWM principle and can glue wires together well enough but creating circuits is beyond my understanding - do you have a sketch or circuit diagram to give it a go....... no point having a 400hp pump when bike only needs a 200hp one!

-

No harm in checking - build it right - build it once!

-

Sorry can't help on this one as a) my GSXR has better alt. output and b) I added a bigger AH battery to give a better buffer. Was going to suggest dropping FP and increase opening times - but Arttu's PWM solution sound the better option? @Arttu- on 1/2 power do you still need to adjust inj. times to compensate - or run an alternate map?

-

Just checked my mapping - bearing in mind its a 2.0L Zetec engine ! Coilpack with 3000us setting (I used 3500us with dyna greens and Motec ECU on my bike), Throttle transients - dunno! Using the settings from base map, std. Mondeo injectors (200cc I think) 0.7 dead time. Regarding the Throt. Transients - DTA has 3 bikes mapped - all suzuki! - and their TT's do vary slightly but not massively to each other or to my zetec tune so would safely say the settings have 'minimal effect' - just smooth the rough edges on accell and decell? Hope that helps.

-

Could be right! - have semi downdraft float bowls?

-

I have one on my Mk2 Escort - what problems?

-

The ID bore would tend to suggest 36mm OD so not 1100M carbs which would be 40mm OD - but they could have been swapped as 40mm's are a PITA to tune easily. Looks like a DJ needle but its a while since I've seen one! DJ main jets are sized in steps of two - 132, 134, 136 etc and only fit DJ emulsion tubes - threads are different as I remember

-

The DOT head will only fit one model year of the 750's - sorry I can't recall which - DOH. Between the 90 and the 92, I'd pick the 90 - it may have a slightly inferior inlet port compared to the 92 but came with screw and locknut tappets and so a wider range of aftermarket cams. Unless the class or race series requires the use of 'stock' CV carbs - buy the RS38's or (my prefered carb) the Keihin FCR39's............unless you can afford TMR's. Knowing 'what' cams you 'have' is of interest only if selling them - knowing what you want aftermarket is more crucially important IMO.

-

What ? Like one of these things? Prefer the second type - plenty of gravity flow to supply an S&S draw thro turbo install for me. Just don't fancy that small area in the sintered type!

-

I don't remember! I got an 1100 alloy arm and put it in my 750 frame - don't remember changing anything! Certainly didn't drill the frame - biggest I have is 13mm But a file could have seen some action......... but don't think so!

-

Straight swop - did it on my 750ET about 25 lifetimes ago!

-

Not wanting to sound obvious but if its a 'race' motor throw 'race' cams at it - then it's not an issue? You are in Trumpland and have some of the best cam grinders available - use their expertise. And I think the CV's (if you are keeping them) will benefit from dual K&N's rather than singles........ just sayin'

-

And the DOT heads never came with Shim adjusted valves so it couldn't have been a 91' 750! The DOT heads are largely the same ie. same valves, only the cams varied

-

If they had a stroke of that magnitude they'd be over 1600cc - YeeHar! Early bikes GSXR 1052 etc. had 58mm stroke, the later GSXR 1127 had 59mm stroke. Bores changed by a mm as well. The Hippo was a GSXR with shaft drive added and equally tuneable!

-

Is that piston back to front but in the right / wrong hole - or is that how it came from the boring place? Only reason I ask, is I thought the 'larger' valve cut-outs on the piston would be for the inlets - I know it's not assembled, just looks odd?

-

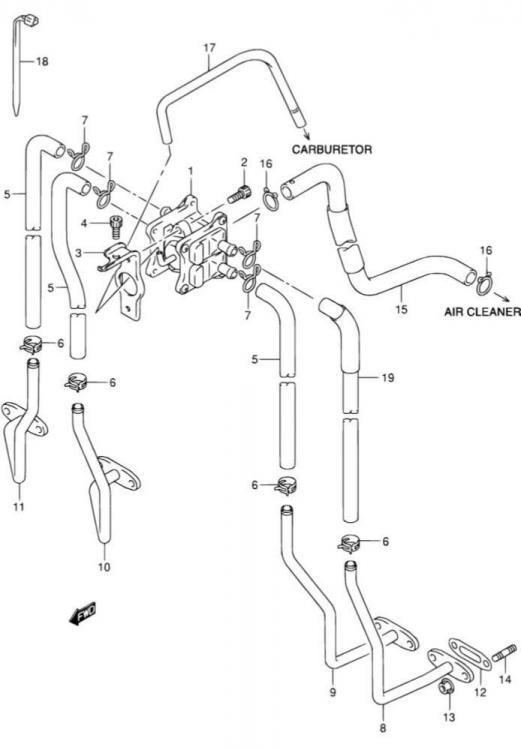

This is the rats nest of crap to be removed and once removed the oval pieces that bolt to the exhaust port need blanking with plates - some performance places do cnc plates or just cut some 3mm alloy plate and shape - leaks here will cause loud backfires on de-cell. Pipe 17 to the carbs can be blocked with an M6 screw and a zip tie to hold in position.