-

Posts

8,499 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by clivegto

-

@ChadillacYes I heard that as well all I am pointing out is this set up works. Bike is completely rideable throughout the rev range it can be rode as a touring bike or a super bike. Good luck with the build.

-

-

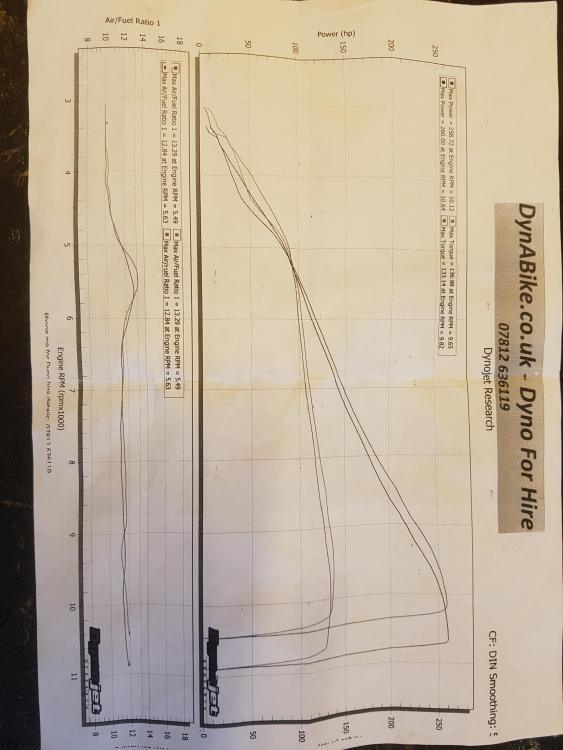

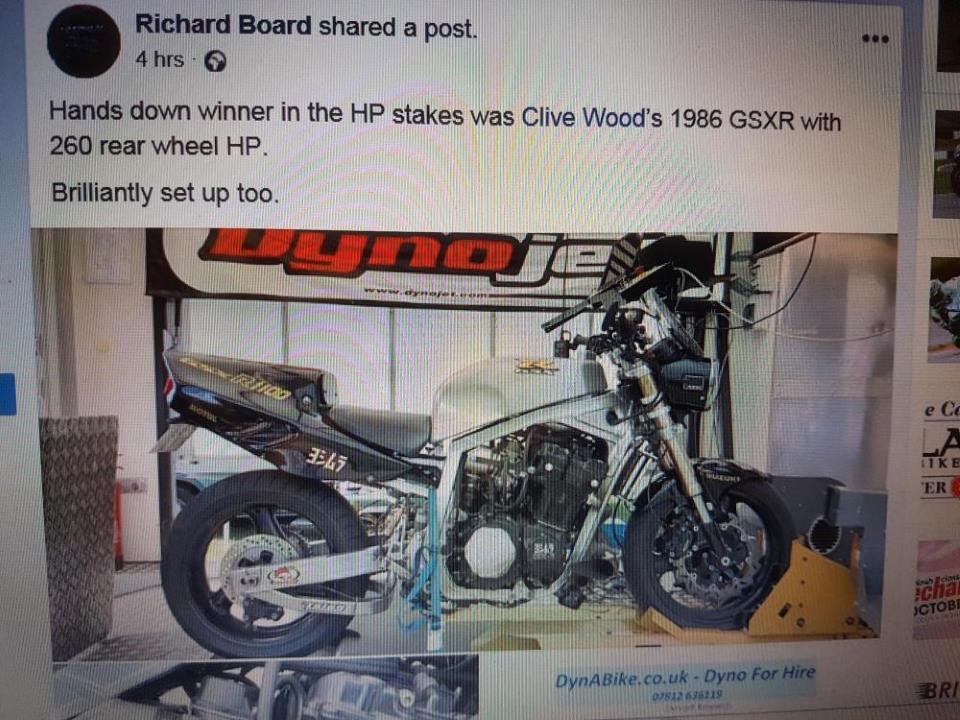

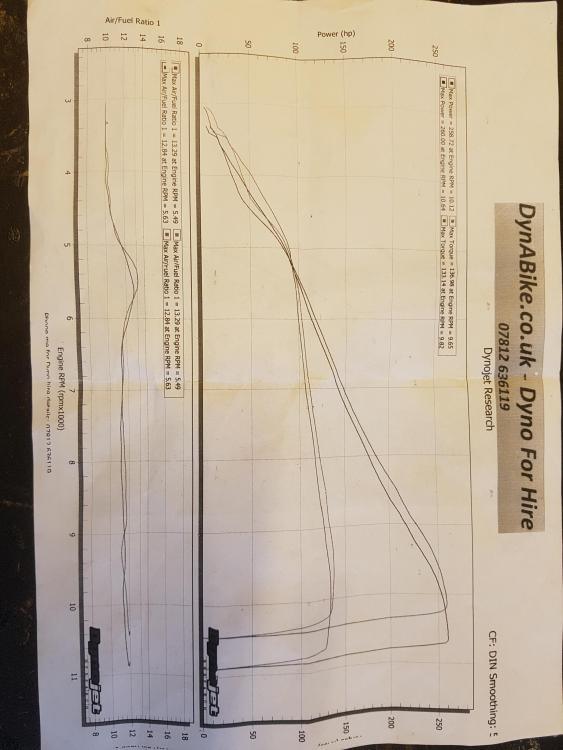

Dont know but I used mk1 busa rods & pistons with 2mm spacer no base gaskets just the 2mm spacer. Pistons were 1/2mm down the bore, head had been flowed & had big inlet valves was possibly skimmed as well but still had 27ml combustion chamber area with 1mm cosmetic head gasket worked it out to be 7.95:1. When I first built the motor put the pistons in wrong way round did over a 100 miles then it was pointed out to me in my thread build so put them the right way round lol. As you know Rob it is making 260hp with 136lb torque with a good power curve & nearly 3000 miles on it this summer so shows this set up works.

-

3 cylinder SRAD

clivegto replied to nopokewithoutsmoke's topic in Water Cooled, V-Twins, Singles and 2-strokes

Unbalanced carbs can make the revs hang. -

OK but they are 79mm making it 1186cc in a power screen motor. You will need to do a dry build to measure the deck hight & volume mate.

-

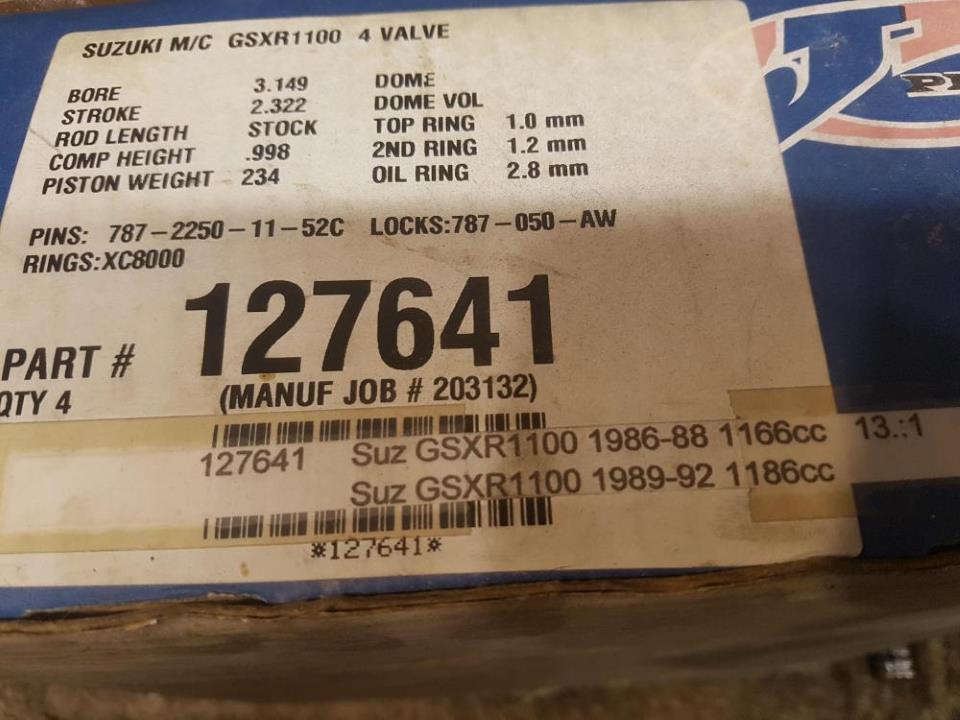

@DuckndiveIs right they have been machined down, I have a brand new set sat on the shelf I never got round to using yet. 79mm pistons with a comp of 13.:1 1166cc for 1052 & 1186cc for the 1127. You need to do a bit of measuring.

-

Got any closer up pics @Swirl

-

Nice, they are not high comp ones. Tell us about the blower man.

-

Love this idea do you happen to have a pattern for it.

-

What other cam springs are avalable ?

-

Both swinging arm are 1st gen r1.

-

No not really the r1 arm in my pic has a 6 inch wheel but will only work with a 190 tyre & the one with the standard arm with the brace welded on has a 5.5 with a 180 tyre.

-

R1 arm can be fitted to a slabside frame but it is a lot of work. Much easier to cut the brace of the r1 arm & welding onto the gsxr arm.

-

Cooler than frozen penguin piss

-

Got a pic where it snapped mate.

-

As has already been mentioned no more than 7psi. First time I ran a turbo set up on my b12 (not the scratcher) it destroyed the pistons between the the piston rings.

-

My one is a street bike with a wheel base of 1440mm at the moment. Have done 2650 miles with this set up this summer so far.

-

Build it properly, do a dry build to do your own calculations as engines can vary a bit, that way hopfuly you only have to build it ones.

-

Nice project you got there. Gs or gsx or even efe motor would suite it but are heavy & expensive to buy & tune. Gsxr 1100 or bandit 1200 are lighter cheaper more powerful easier to tune.

-

I use gen 1 busa rods & pistons with 2mm spacer plate, comp was just less than 8 to 1 no problem with a tight cam chain on mk1 b12 engine. TDO4L turbo making 260hp at 16psi.

-

They got married yesterday. Congratulations to you both.

-

-

That was me lol. It was a second hand turbo kit for a b12 I adapted to fit the 750 slabside frame. Engine is b12 1216cc busa rods, pistons 2mm spacer plate, big valve head & flowed by Rodger Upperton, gsx1100f cams, b12 carbs, lock up clutch held together with APE stuff.

-

What about shock length.