-

Posts

234 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Lachie04

-

I have a set of 89 750 gsxf forks in the garage can't tell you from the yoke but overall length from top to axle center is 785mm. As you probably know the bars sit atop the yoke from memory I think they are @ 30mm odd thick that's with no compression obviously

-

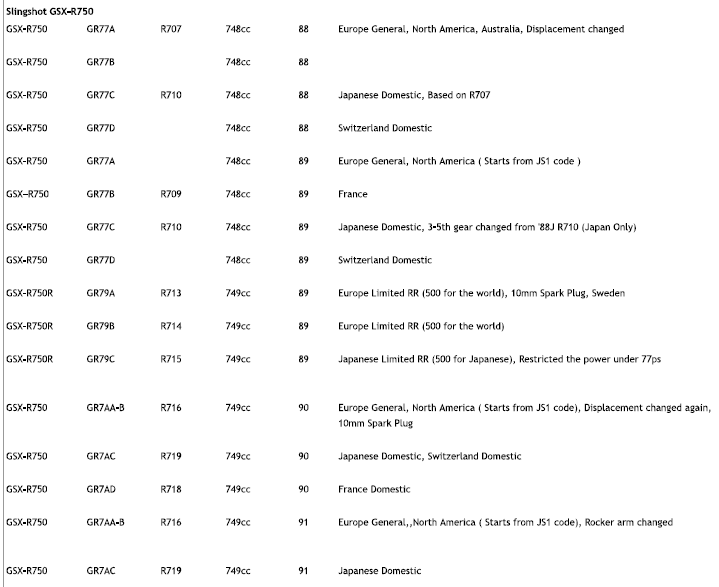

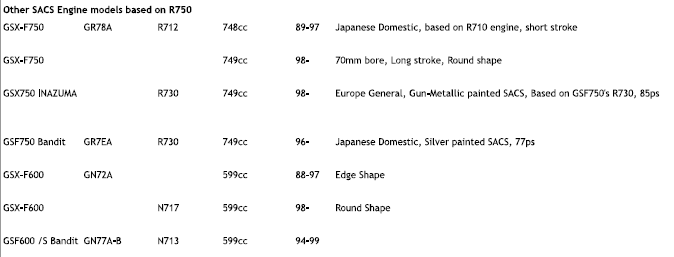

'00 gsxf 750 long stroke has a hyvo chain just keep in mind need to swap cam sprockets if using roller chain cams aka gsxr 80's and dial them in,, likely need slot them also

-

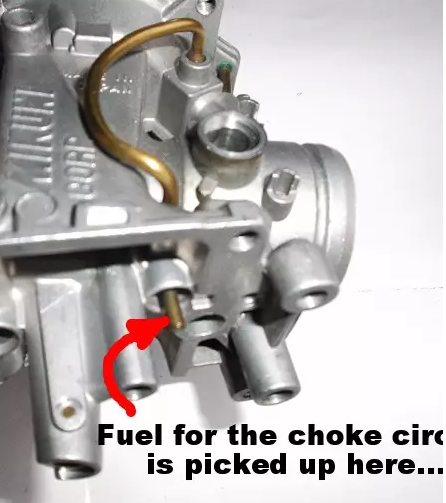

I understand it's an enrichment circuit for the choke Should (have heard) only affect the starting circuit with choke on when it draws additional fuel shouldn't be a running problem but otherwise should be fixed (somehow???) Don't know how effective something like JB weld would hold up but they are swagged and glued in originally by looks e.g. different carb but same principle

-

They are not off a GXF750 the pilots wrong for the 98+ and the web between the pilot tube and main is not there for the pre97 regardless of the choke setup

-

Don't have any experience with jet kits usually just get them over the counter but hear the needles do have multiple clip positions, it is part of the tuning process. My pre 98 carbs had 5 clip positions as did the replacement OEM (Mikuni) ones I got

-

Hey, I picked up a track bike to use for some spares last year the guy that built it up had a 99 GSXF 750 motor in it running TPS '99 BST36 carbs and K&N pod filters, with standard headers and a CBR muffler. I never rode it but by all accounts it went pretty well (for a track bike). I did start it up and it idled and accelerated at stand still ok with no pops and farts. It had #145 mains, (and if my 2x glasses and magnifying glass is accurate) #60 pilots Mikuni jets. The Needle was on the bottom row and it also had a washer under the clip. Personally I wouldn't use the pre 97 carbs my experience really expensive to rebuild especially if you need to change the plastic slide guides which wear out in about 30,000klm, and I believe the castings deteriorate, break down as I broke the throttle holder part without much pressure at all (just my theory anyway). If you need to rebuild them it's a better option to go aftermarket. But since you've already got them once tuned up they work reasonably well Just for interest here a pic of worn and new slide guides They wear out as indicated here which then leads to accelerated needle and needle jet wear as well as closing up the bottom of the slide.

-

Just the ones on either side of the adjusting screw, check for air leaks and catching throttle, visual sync the butterflies to the first air hole I would think the spring that's missing would be there to stop the screw moving

-

This other thread may help http://oldskoolsuzuki.info/forums/topic/7430-carb-rubbers/

-

lifting the clip to the top -1 places the needle further into the main jet making it leaner in the mid range 1/4 -3/4 throttle by putting washers under the clip your lifting the needle out of the main jet thereby making it richer in this range Putting two washers under the clip you might as well just put the clip into -3 The washer trick is for when the OEM needle has only one clip position to make it richer

-

-

I'm not sure you could do that maybe someone with better knowledge can jump in. The manual only references the end notches as identifying the RH side of the cam and to correctly position the sprockets to the cam, naught about timing. There are quite a few differences between timing marks, link lengths (number of pins) between cam sprockets (between the two different chains and motors), lift, duration, timing, point really was when changing things up like that I have found even if someone says "done this a thousand times" there is always the possibility it can go horribly wrong. Any changes like that and I would recommend do the whole lot = degree, timing, piston to valve clearances just to be sure it's going to work.

-

Definitely need to degree cams, I just put a Dot head on a later motor having to change sprockets, initially with the intake remained at 104° but the exhaust went to 108° slotted the gear back to 105. Very possible yours went that way also. GSXF head = DOT head ?? or latter??? smaller valve smaller bore one?? if it's a latter model one with the similar cam chain and sprocket would be my bet your going a bit backwards on that

-

^^ If you take the bowl off and there's a rubber stopper on the pilot jet with a passage/port between main and the pilot then will be a teapot carb they usually came with an extension on the idle adjust to the left hand side but as that doesn't could have been modded or just different country

-

B should be DOT head cam Some more info here http://old-skool-suzuki.proboards.com/thread/1385/gsxr1100-cams-bandit-1200-numbers?page=2

-

Cheers for that gives me hope I was thinking this would be a dead thread. Ok out with the heat torch I go

-

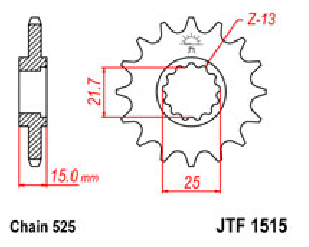

Sounds a bit bulky when I spaced my 89 750 out I just used a couple of washers from the local hardware but as long as it doesn't counter wear on something you probably could. I've gone better than that now by using this sprocket and surface grinding the small side down which can give you up to additional 8 mm spacing but that probably wouldn't work for you as I am running a 525 chain PS it's off a ZX-6 95-97

-

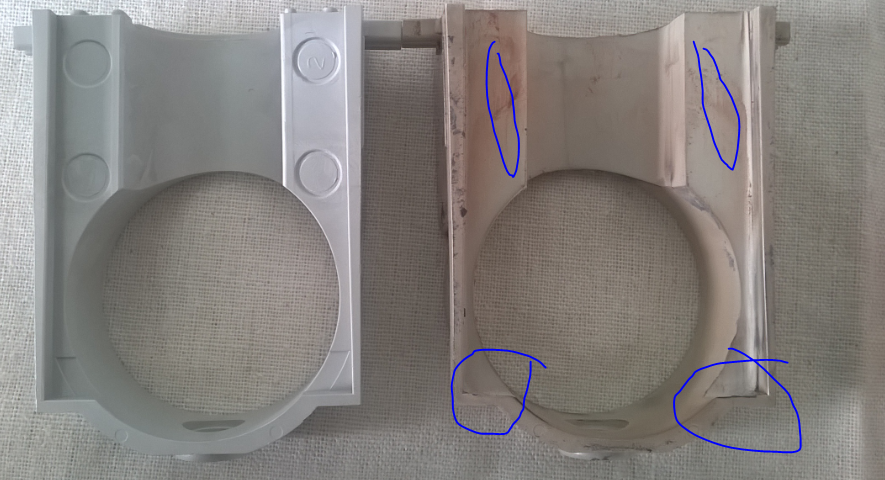

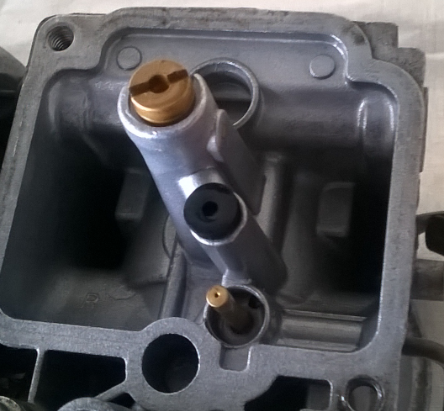

Hey So I have a few bits and pieces around so thought I would play around with building a 1052 six speed. Have acquired a few bits and a DOT head along the way. Yep problem is wasn't really as described by trader "good condition" should have read *(&&%^*& stuffed really First thing I noticed was OP had mangled the stiffener bracket between #2 & 3 cylinder bolts and cut off the washer type end OK I can work around that but then "big one" was found one of the Brass tubes that carry the head cooler oil down to the top of #1 cylinder is completely missing ????? how do you even get these out ???? So my only saving grace is I have another head which I will never be putting on another motor which I can butcher to get one of this Brass tubes. Anyone ever had the pleasure of removing or replacing one of these tubes?? I have tentatively tried very softly to twist one out of my spare head but seems very tightly wedged I imagine they are pressed in perhaps heating the head could loosen it??? Any (helpful LOL) ideas would appreciated

-

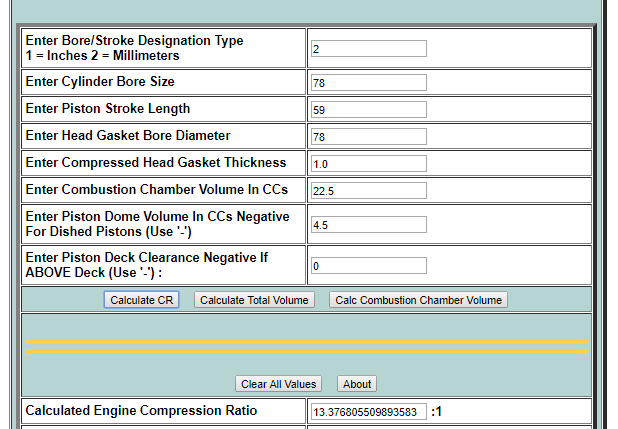

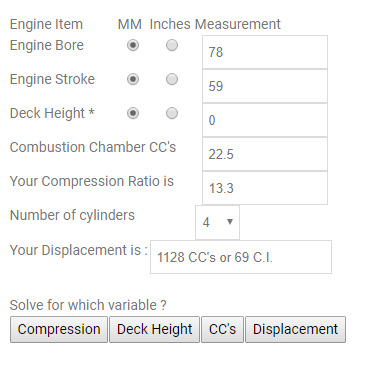

I think the volume calculation is not the same as displacement have done it a couple of times on different calculators and still comes out to 13.3 (OR .4):1. Wouldn't worry about the other I think it is a swept volume Or (281.7 + 22.5) / 22.5 = 13.5:1 (rough) To be honest if I do it for a dot head and barrel it comes out to 9.9 or something and I was pretty sure they are supposed to be 10.9:1

-

Recently did a rebuild and my guy cc'd the head the DOT head volume was 22.5 ml and the 73mm 750 piston crown was @4.31 ml (probably within a whisker of a 1127 piston would suspect) at least give you a ball park to look at There is a few sites that have calculators for CR some are different and come out with all sorts of different values but this one looks reasonable unless you want to work it all out yourself http://www.csgnetwork.com/compcalc.html

-

Obviously been done a few times here and thinking of doing it on another motor build but.. Question I've been meaning to ask would you not have to machine out the squish band to match the new cylinder diameter? I would think the sharp edge would create a hot spot in the chamber

-

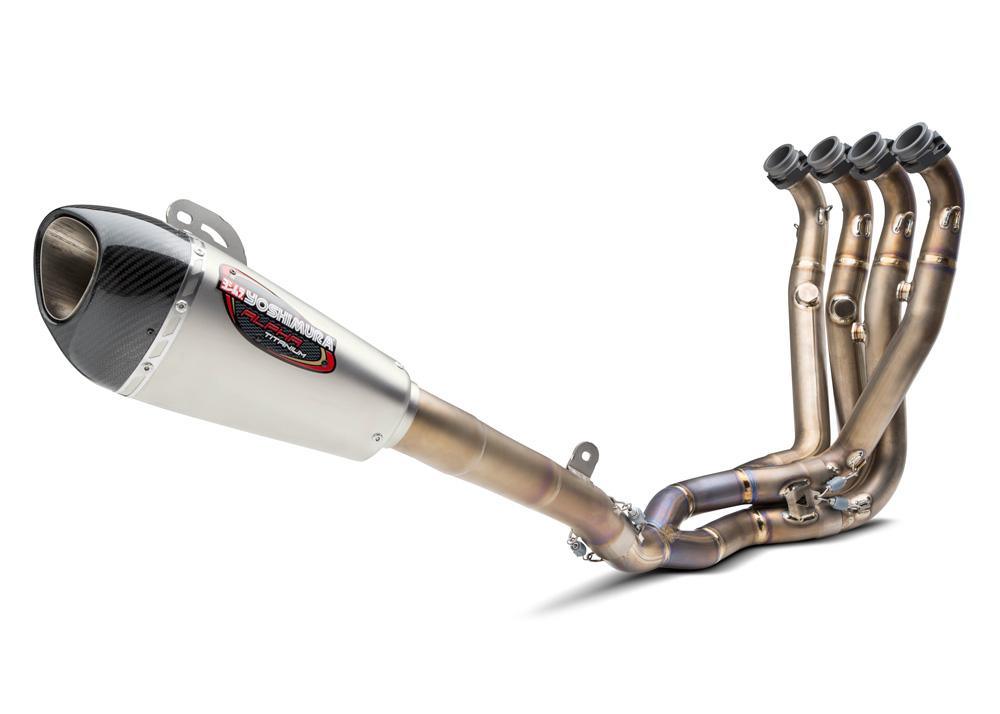

Heres a couple of recent Yoshi examples I've found for the GSXR1000, maybe this tech is not dead Yoshi's spin is "dramatically improves power and torque across the entire rev range" Interestingly the second one also includes a balance pipe closer to the port which I always thought was there to "re balance" 421 systems

-

HI guys, new here on this forum been bumping around Katriders for a while but as I have a project bike going on at the moment and wanting some info thought I'd put it to the brains trust So my project includes a tweaked over gsxr750 '89 motor and am getting a new stainless 4-2-1 made up for it. Looking through some performance mod's for the exhaust and there is quite a lot of support out there the correct (or better) pairing for the headers is pairing 1-4 & 2-3 together so this brings the pulses/scavenging back to an even 360° on a 180° crank. Wondering if anybody has ever had any experience with this pairing and outcomes, according to many it's supposed to even out the torque curve. yes it may look a bit strange but then I am too LOL