-

Posts

234 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Lachie04

-

Mk2 1200 bandit What's the thoughts/experience on this, will crank survive ?? It skid down the road @ 50kph It's gonna be an insurance job so I'm not going to be pulling it apart to find out

-

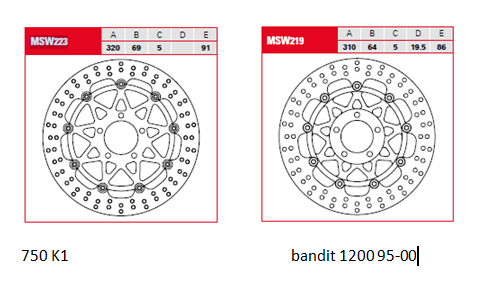

There is no 320mm disk that will fit a bandit wheel your best option is to get the right wheel for the forks or do something like this (in reverse which is a shite load of work)

-

-

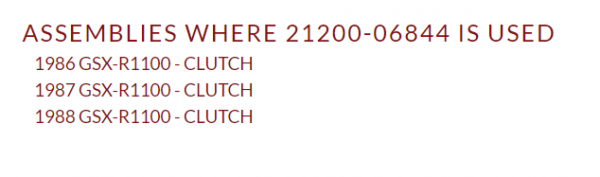

The primary drive gear is different you need to match the gear to the crank. Although the gear can be changed with some degree of cutting and reriveting you would still need to find that particular gear

-

-

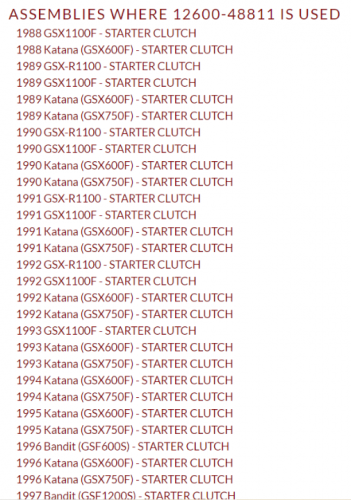

I'm planning on replacing my 1052 starter clutch with a 89 "750" teapot one the part numbers line up and as far as I've got the center bolt fits but waiting on a puller to get them off The 750 one appears a bit lighter than the 1052 one and the cranks are the same (ish) in dimension I have both and from memory the gears counts are the same for the 750 / 1052 I can take some pic's after work if you like but 88 is a 600 ??? so don't know IDK check the parts fische for numbers I understood the 1052 and 750 were interchangeable from my research

-

95 teapot is based on the K model GSXR engine very different to the longstroke GXSr750 L just about everything is different The teapot motor went to longstroke 1998

-

If your running a DOT head than you will lose compression even more by going to a 1100 head. The DOT head standard is @20cc the 1100 depending on type can be @26cc

-

Yep could steel the Mrs ultrasonic cleaner she bought to clean her jewelery is there any special mix for these things?

-

Hey fokes Got a set of 750 89 K forks to fit up for a post classic but the rebound screw adjusters are pretty jamed, one I can only get a half turn on. Is there any other compatible fork caps around that anyone knows of with preload and rebound screws? They only seem to have been used on 88 - 90 750's and look a bit rare Or any suggestions on freeing them up? With the o rings inside I imagine heating would not be a great option. Cheers

-

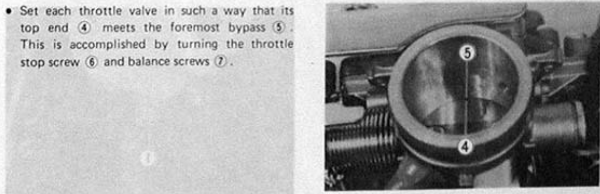

Not sure how you can set that with spring loaded slides. Bench syncing CV carbs is done be setting the throttle butterfly so it just comes up to the bypass hole on the intact side. Then when all together vacuum sync them

-

I always thought they said that cause they're so hard to get out after you've split the cases is just easier when the engine together as it doesn't stop you getting at the crankcase bolts same with that oil relief plug bolt that's torqued up to like 70000 nm in the sump

-

-

That sounds like a plan I was someway thinking skimming the dome but didn't know if it was a good way to go. I can get that done pretty easily. It is actually for a track bike but still looking for some longevity without overstressing the beast. I think mid 12's would be high enough for me.

-

yeah might be the idea I believe a base gasket is @ 0.01" or 0.25mm so a 0.03" spacer plate would give me .5mm below deck and @ 12:1 0.04" = 11.6:1

-

Hello fine peeps I'm building up a 1052 with dot head and after painstakingly measuring everything along the way including cc'ing the chambers and piston dome displacement (by my calculations) the final build works out @13.4:1 CR. chamber volume 21cc (slightly deshrouded), dome volume 5cc, zero deck and 0.8mm compressed gasket 3.6cc 263/19.6 = 13.41 Which is too much for my basically stock motor build .... well for me anyway. I could live with @ 12.5 which is basically what you would get with a B12/Dot head setup (I think). So options I'm thinking of is either a thicker head gasket 0.04+ compressed thickness (currently 0.03 or 0.8mm) or skimming 0.6mm off the piston dome both of which would give me an extra CC and then @12.5:1. Trouble is I can't find any 0.04 gaskets for the 1052 . Any thoughts Or random idea a second base gasket ? Cheers

-

Well FFS bolted it up again for the 5th time and it's now fine IDK ok onwards

-

That does not sound too encouraging .......... might have to find a dial gauge. have rest of bits to build up a 1052 with dot head was a bunch of stuff left over from a previous put together, from my original 748 cases

-

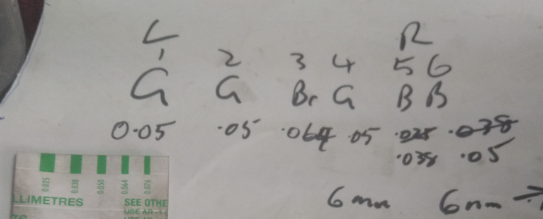

Ok so putting a 1052 crank in a 750 case quadruple checked the codes and ordered the shells ok dry build with plenty of oil on the bearings and thinking it should spin over pretty easy considering there's probably some wear on the crank journals--- no. Putting a spanner on it felt like a full motor when turning it. So got some dubious plastigauge (was very brittle don't know how old it was) checked the clearances and found roughly and I say that cause the 0.064 and 0.038 were on the high and low side just was closer to those than the other L-R 0.05, 0.05, 0.064, 0.05, 0.038, 0.05 So service limit is 0.08 so their all in limits but damn hard to spin the crank. The only other crank I've ever replaced was an old RG with roller bearings so don't know how these are supposed to turn out. How tight (hard to turn over) are they normally?????

-

-

These guides make the slides loose and let them wobble around causing accelerated wear https://store.moto-lab.com/articles/bst36-slide-guide-wear-indicators If rebuilding old carbs I think is a must and worth checking

-

Yeah damn auto text lol https://store.moto-lab.com/products/655/throttle-slide-guide/893/suzuki/gsx-r750/1988/usa There's also a article on that site about the wear to the guide What worked for me may not work for you I was running standard air filter and a home made exhaust Here's something I wrote on some other site So rechecked the Float heights and I don't think I must have done it right the first time and ended up adjusting them all to around 14.5 mm which was about a mm lower then were they were set so this should make the bike a little richer. Put the pilot down to 3 1/4 and was much better but needed more.Down to 2.5 and was way worse so ended up on 3 turns out and pulls really nice when warmed up.GreatI ended up syncing the carbs at 2250 revs I had started out just doing it at about 1500 revs as I had read you should just do it just above idle but decided 2250 was probably a better place to do it. I don't know but anyway.The Factory Pro tuning says you should tune the low end for smooth idle and 4k 2nd gear operation which it does, in fact it goes great at any acceleration.So now it is just at 5th or 6th gear cruising it has a little lag at 4,500 to 5,500 revs roll on and if I slightly drop the throttle a little feels like it's starving which is more just annoying then anything.Having spent so much off time trying to sort the tuning I've just decided to get it back on the road proper and ride it for a while maybe if it gets to me too much or when i get bored I'll rip it apart again and try the float at 14mm i'm thinking it maybe still be a little lean in that area or maybe play with the needle again to see if raising it back up cures the lag in the 5-6 gear range midrange cruise state, but is accelerating so great in all other ways, I don't want to stuff it up .....Postscript:cause it was quick and didn't take a lot of disassembly I lifted the needle back to the original middle position and it fixed the leaned out midrange but somehow the lowend was bogging down. So i relented and took it all apart again. Went over the float heights spent a bit of time on this and made sure they were all at 14.5mm turned the PA screw down to 2 3/4 and vacuum sycn'd the carbs at 1750 this time.Now it pulls absolutely great through all the rev range and there is just the slightness hesitation @ 5000 in 5th and top at cruising speed which i can live with ATM. Some thoughts on this is either the pipe has a little flat spot around this range which is why it's been difficult to tune this bit out or maybe I could go one size up in the main as it's just struggling a bit just on the needle. So the carb setup I've finally got is 5EZ61-3 needle jet, 105 Mains,37.5 Pilot jet That's was on a teapot motor and the main jet could have gone bigger but I was starting of standard and working from there up hence the small main jet but got tired of tuning so when it started going well l left it alone