-

Posts

1,267 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by baldrick

-

yeah, its a strange one. i guess its coming out though, i might have a gsxr one stashed away from previous swaps.

-

looking at one on bay shows it being threaded all the way to top of the stem. this one aint, its got an internal thread at top . wondering wtaf its off? looks like i need a new stem machined (groan) Any ideas?

-

hello, im trying to figure out what this yoke is from. it was sold as a 750M but it looks like someone has replaced or modded the stem. i dont remember ever seeing weld to the underside like this, but its got the steering lock cut out which would suggest its not been machined, more likely taken from another model and adapted to fit...another look tells its got a couple of spacers to the bottom of the stem, below the bearing. holes are 54mm, which computes , bottom bearing internal diamater is 28mm, but the top, where the top yoke slides over is 23mm, and the top yoke ive got (off a L model) is 22mm, top yoke is 50mm holes, and top yoke deffo looks like a 750l,m so i guess what im asking is, is the bottom yoke stem 22mm at the top on a std 750 L,M

-

it will hang lower on a 750, if it was designed for an 11, so you might have issues with the fairing

-

Project No3-Busa

baldrick replied to Allspeeds's topic in Water Cooled, V-Twins, Singles and 2-strokes

it is accurate, mine only made 158 with cheap aftermarket exhaust, cheap can and baffle in it, and that was after a engine rebuild, so its probably about right. any progress? -

think i would be tempted just to fit a new base gasket myself. its gonna be in bits anyway.

-

'Busa Gen 1 brake upgrade

baldrick replied to Jonny's topic in Water Cooled, V-Twins, Singles and 2-strokes

i would go with the nissin 4 pots too, much better brakes than the 6 potters. -

Project No3-Busa

baldrick replied to Allspeeds's topic in Water Cooled, V-Twins, Singles and 2-strokes

intake cam to replace the stock exhaust one can liberate another 10 BHP. Good luck with the build, i look forward to seeing it on the strip. -

if you're matching an existing colour, go to a spray shop which has a photospectrometer, and they will scan your original colour and mix up the colour to match it.

-

Hi mate, yeah i wont recommend the paint to be honest, used the entire tin doing the cam cover, alternator and starter motor of my gsxr 1100M. it also spat out some moisture from the can along with the paint resulting in bubbles on the painted surface. it does a job, but im going to break out the compressor for this engine. oh yeah, and vapour blasting....remember and tell them to block off the oilways. i had assumed he would have, but checked before putting the cover back, just as well i did. this little lot which i got out of the oilways with a length of welding wire, would have royally fucked my engine in short time...............:(

-

i dont own a mig, just a tig, and have no gas for it just now, so its with the machinists.

-

Yeah, that's what i should have done, im sure itwill be another expensive mistake. I dug the old motor out today, its been stuck in the far corner of the garage for years. i had to lift it over my TL1000 to get it out. Not sure if i have found some more strength as i get older but it wasnt as heavy as i remembered. Anyway its at the garage door and will get a wash with thinners before getting some hycote engine enamel gloss black spray. i painted it before i put it away so its not seen any oil etc, but the paint i used the last time was utter shit (simoniz stuff) it literally comes off when you rub it hard enough , its crap. Im hoping the Hycote stuff is better , its got promising "serious health warning" on the side i know i would be better off breaking out the compressor, and proper 2 pack paint, i might yet, if this stuff is also crap. head has been poked by TTS previously and rubbers matched.

-

swinger off to the machinists to get remnants of hardened steel bearing shell machined out, somehow, hopefully. tried to remove the bearing with slide hammer/bearing puller, but just succeeded in pulling the centre of the bearing and needles out, leaving the outer shell, fuckity fuck. So tried outer bearing shell with slide hammer with blind bearing removal end, but because the shell is hard to the internal stop there was nothing for it to grip too. TRied loads of heat, tightening slide hammer attachment to F tight but nope it was sliding along the hardened steel inside surface. Bah!! So an expensive drink fuelled fuck up on my part... gonna be a minimum of 2 weeks because they are flat out busy. hes talking about using an end mill to try machine the hardened steel shell thin enough to pop it from the opposite side. lets hope its possible.

-

vapour blasting dude just sent these pics. This guy is really good, his prices are really reasonable, and he is conscientious, unlike lots of chancing f*ckers in the bike industry who promise they can do a job and let you down, or take weeks to deliver. Jon Rix at vapour blast solutions in Aberdeen, get my seal of approval. Steel parts are away for primer (included in price) you want to have seen how scabby and manky these bits were on the "before" pics. i want a vapour blaster now...

-

aye i know, but most of us just keep quiet about these things haha. echhttt, ive decided the swingarm needs to be black to match the frame so, after putting it all together not even a month agao, its in bits again. will drop it off at weekend.

-

looks really good. Whats the front end off, and did you have to extend the forks at all?

-

Yes do that, start a thread, plenty of interest. todays sage advice- dont put bearings in (the wrong side of the swingarm) after a heavy night on the glenlivit 18 year old and cider.....while continually wondering why its so tight, but hammering on regardless..................doh....result= 1 fuct bearing with the outer shell stuck fast in the swingarm recess....i should have my tools taken away from me really...........

-

haha, aye you're right there, ive also got my efe/gsxrs'and a kat to finish/start. i started efe/gsxr about 15 year ago......did well, then it all ground to a halt. its had most of the work done too.... arghhhhhhhh!!!!!!!! stuff went off for vapour blasting. 1100m cam cover, 2 gsxr mudguard support brackets, set of footpegs and levers, 2 sets clip ons, pair of nissin 4 pot calipers and slabby fairing frame= 14 items, 90 quid, bargain, i would say... ive seen the lads work on fb, it looks mint. pickup next weekend.

-

the rf 900 front end is really short, even compared to the bandit one

-

right, well, as usual, progress has been about as fast as a semi retired tectonic plate... but ive not been a completely lazy bastard. i removed the old bearings in the swingarm, well, i removed the 2 normal bearings, the needle roller was stuck fast. the new set of punches just slid off the rollers, great work Hongay, with providing punch cut outs that arent deep enough to catch the edge of the bearing , yet another reason to hate Hondas. i got a set of these mofos off the bay of e. that got them out, well it didnt but it did when i heated the alloy to near melting point haha. still its out now, and the new bearings are in the freezer. i also got some stuff for vapour blasting locally, im off to see the boy tomorrow, with this lot,. slabby fairing frame is for another project. i started paint removal on the cam cover but the paint stripper had turned to gel, and wasnt very effective, so fuggitt of to vapour you go. once i get the rolling chasis together things should hopefully move a bit quicker. .....................................he says...

-

good luck with the sale, you shouldnt have any problem selling it -in the real world, .................... away from "pedantic central" here, where they really know how to encourage new members to post more often .......not.

-

As an update, ive got the frame back from the engineering place,they where machined out the bearing housing, after it shrunk. bearing shell now fits, so i will be getting front end on it next week (have son for holidays this week, and hes been helping with my gsxr build. it is almost done, just the cam cover to paint, gsxr shock to fit and rearrange electrics to suit it. hes handy for reaching the awkward front cam cover bolt i was checking out the single sider for the harris and the bearings are as crusty as baldricks pants, so new ones needed. its a weird set up, with a needle roller bearing in one side and 2 caged bearings in the other, another 55 quid ker ching.

-

any progress with this one?

-

harris steering head bearing cup removal from frame

baldrick replied to baldrick's topic in Trick Frames

probably because you did it all theway round and it wouldnt have heated in localised spots. oh well, proper engineer bloke reckons its fixable, thank fook. not really enough to bore it out to next size so the reamer is gonna ream. Might have to loctite the bearing shell in, depends on how much contact area is left, hes confident it will be about 80% contact area at least. Just got to wait till he can fit it in. -

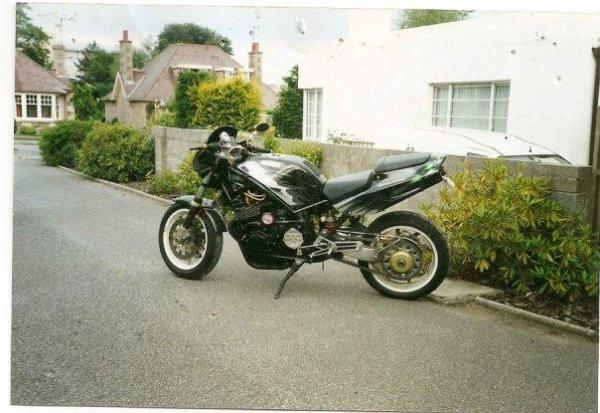

hello, im back again for a rebuild of my harris magnum 2. i had it built up, er....quite .a few years ago, but wasnt really happy with it, so stripped it down. it started with an efe engine in it, and progressed to gsxr power (that should upset the purists, but not as much as it upset me selling the old efe engines for peanuts, to one Dave Beck, drag racer) it used the time to paint it in a lairy metalflake lowrider theme, and stuffed all the bits in the loft for a few years, as you do. Later i decided to get the frame re coated, but before i did i got a friend to modify the frame for yet another seat unit (cbr1000rr one). he bronze brazed on new framework to the original, and replaced the crossmember tube which held the bottom linkage of the swingarm, with a thicker one, as the original wasnt thick enough and was starting to bend . got it all powder coated, not all that well, cos i spent days tapping out the holes that the lazy arseholes didnt plug. new tyres, brakes rebuilt and a few other jibs jobbed. engine is a gsxr 1340, TTS built motor, which will be running 36 or 38mm carbs, as my keihin fcrs wont fit between the tubes . it needs checked and painted. it was pumping out 174 BHP on TTS dyno, back in the day so should be plenty for this lightweight frame to hustle along. akra pipe and a few other nice bits, i would like a different front end and rear shock but am skinto, so it can wait , i must get it built. so anyway it sat like this until decided it was time to build. first step, get the old head bearing out and replaced. strike 1, ovalised the headstock, so its off to get sorted at machinists on Monday, but i will be back, oh yes. heres my collection of bits and what it looked like a wee while ago in various guises cheers