-

Posts

2,589 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by dupersunc

-

2" SU was good for 400bhp on a 2ltr Ford cosworth draw through set-up. 1"/34 should be fine. Burlen Services in Salisbury can supply just about anything for SU carbs.

-

-

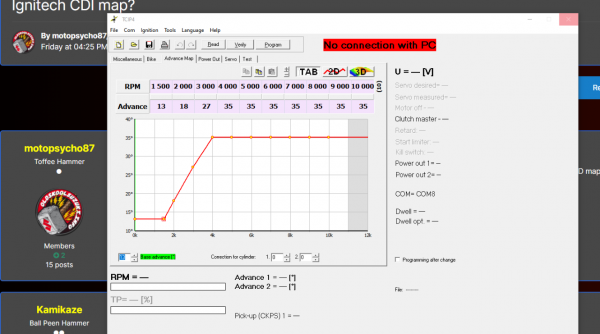

More advance at low throttle openings is normal, for cruising fuel economy, see the old vacuum advance mech's on old cars. Curious why you've retarded it above 8000rpm at 100% throttle? piston is traveling faster so you need to start the burn sooner in the compression phase.

-

I've got a translogic QS on an oil boiler that I picked up cheap, but I'm not impressed with it. The ignitech is the cheapest QS I've found, plusyou get a free programmable ignition with it. As for checking timing, yes you'd have to put your own tdc mark on the trigger and rig up a temporary cover for it

-

It would be worth checking the actual timing with a strobe and your own tdc marks. I have read that the ignitech maps are a little bit out, in that numbers on the screen for advance aren't correct. This matches my experience. I run my motors, 1216cc, hi comp, with a lot of extra advance, 5-7 degrees between 7000-1100rpm, with no signs of detonation, and feel like I could wind some more advance in.

-

What he said ^^^. Ignitech comes enabled and with software to map ignition, advance/ revs, and you can add tps to map throttle position/advance. Also has pit limiter function, and the quickshifter function which can also be adjusted and set up via their software. An ignition unit, quickshifter switch, software and download lead, same as I have was about £200 delivered. I built a complete bike loom from scratch, but for a stock loom Ignitech will supply an adaptor harness to any oil cooled bike for about £15, the quick shifter switch would require a very simple bit of wiring in to this sub harness, and enabling it by ticking a box in the soft ware. No doubt Ignitech could supply this already done if requested.

-

Yes, there's no facility to change it for each gear. I've done lot of work with ignition cuts for gear shifting on far more sophisticated set-ups, andyou don't vary the shift time that much from gear to gear. Biggest gains are in getting it right for the higher gears. With the settings I run all the shots are pretty smooth and seemless. I love my quickshifter.

-

40 m/s delay works fine, not played with it. A mate was have issues with accidentally activating the kill, set it to 40m/s like mine and it's been fine. I use the Ignitech load sensing switch, it's about £65 Euro. Works fine. Using the load sensing type of trigger is the only way to go. It's easy to wire, though a bit gets lost in Ignitechs CZ to English translation.

-

I run my 1100 motors at 50m/s, its smooth as silk. 40m/s is too short and harsh. 60m/s is ok, 70m/s it gets jerky. A decent q/s isn't a straight kill, it should feed the spark back in over 10-15m/s

-

The Ignitech stuff is really good, especially for the money. You cna get a programeable ignition with quickshifter for less than any other quickshifter on the market. I've run them on 3 bikes now, and they are great, as good as all but the very best quickshifters out there. I run mine at 50ms kill time. You've got Liam Venter at FastBikeGear in Auckland (yeah, I know, but he's closer than Europe) who's really knowledgeable on and stocks Ignitech stuff. Be worth dropping him a line

-

Just do them to the torque setting in the book, no need for the plus 30 degrees or what ever. Never read any recommendation to replace them. You can find a pdf of the factory workshop manual on line that'll you everything you need to know

-

Old Spondon Arm for Slabside 1100 ....will it fit 750F ?

dupersunc replied to Moriwaki1105's topic in Oil Cooled

That's lovely. Far too good for you lot. Sell it to me. -

Check the big ends.

-

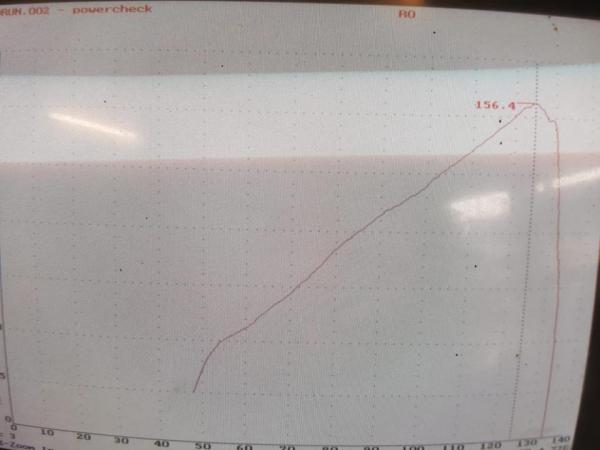

Well a stock healthy gsxr1000 will blow 150bhp through those headers. It has to bea fairly trick oil boiler to find the limit of the gsxr1000 system.

-

Bend them cold. Done 3 or 4 sets now. Always done them by hand. Can be a biugger to fit first time.

-

Srad hub has the same sprocket of set as the 6" rim. That said I fitted an srad rim in a 750L arm with top hat spacers and 6mm machined off the sprocket carrier face and a 3mm offset front sprocket.

-

Nonsense.

-

Fit the 1100 link, or a 2002-05 r6 shock. Both need a little fettling to fit, for clearance on full droop, and the the r6 shock need the lower eye need narrowing a couple of mm. All DIY jobs. Helps the handling a treat, and gives more ground clearance.

-

-

Just make sure you're the correct gear in the first place. Torque isn't an issue on these motors, no need to de tune them.

-

Torque high up the rev range is win win. You gain power and keep the torque. Torque low down at the expense of torque up high, loses you power and gains nothing, other than cruising in a higher gear.

-

Nice build. Torque is never an issue on these motors. If you need more torque, you have that little lever under your left toes. I don't think you'll have an issue with this motor hitting your goals and scaring the shit out of yourself.

-

Does he know anything about gearing?

-

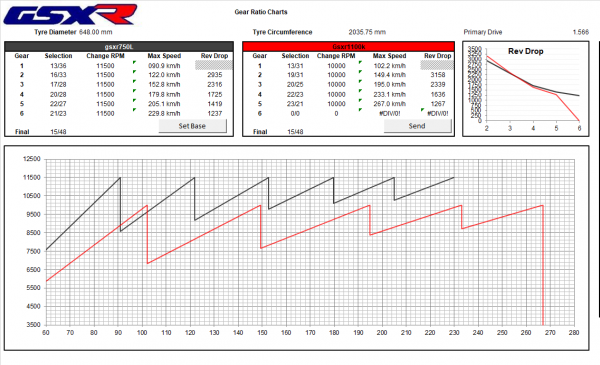

Way to confuse the bloke even further. Ignore that ^^^^ it's incorrect. Gear for high top speed= slower acceleration Gear for Lower top speed= faster acceleration Simply. Stock Gsxr1100 gearing 15-48 is good for a genuine 160mph, with a tail wind and stock aero, and a very, very long straight. Your proposed gearing is theoretically good for 168mph. a Gs750 with a stock Gsxr motor won't pull 168mph. aero drag will stop you before you run out of revs. go with stock gearing

-

The 1100 link will make it worse. 320 will be too long. 310mm is about as long as you can get away with iirc.