-

Posts

2,587 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by dupersunc

-

I space the vack of the tank up 1/2" on my 7/11 builds.

-

Heli coils fitted correctly will be more than adequate for the job.

-

CRMC are a bit of a night mare. You need to speak to the eligibility bod at the club. What they say goes, doesn't matter if its a period correct mod or not. 1100cc motor is a definite no. Tt will have to be 750.

-

To temove gear shaft, you need to remove the clutch and primary gear. Then remove the circlip in the picture above and tap the gear shaft out through the clutch side. To degrease, brake clean, then acetone before welding.

-

Please build it like the last one.

-

Ignitech programable ignition system maps. Spit back through carbs.

dupersunc replied to alfiestorm's topic in Oil Cooled

Thats where I would start. The ignitechs are pretty good, and these engines arent that sensitive to a few degrees of ignition at low rpm. -

Ignitech programable ignition system maps. Spit back through carbs.

dupersunc replied to alfiestorm's topic in Oil Cooled

Sounds like the mixture is too lean at low rpm. -

Robinsons foundry some times have deals on gaskets and o'rings. They were less than half price in one of there deals a couple years back so I stocked up. Worth keeping an eye out.

-

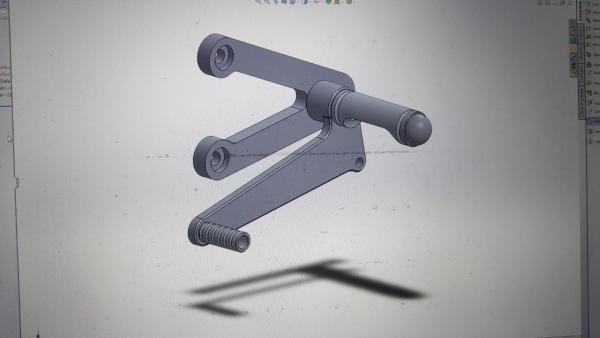

The maximum you can get from the linkages and a bit more with the grinding.

-

A 45mm longer shock will have the linkage hard against the stops. You can grind material away here and there to gain a bit of clearance, but 45mm is a lot. I run and early r6 shock tgat is around 18mm longer than stock, still had to grind material away to get enough sag in the rear suspension.

-

-

41s. You've built the rest of the engine for power, why try and strangle top end.

-

The Motion Pro set-up is aweful in my opinion. Way to much travel required to get full throttle.

-

Not in a position to do so at the moment. Sorry.

-

Great footage at the start of my mate Paul trying to glue the rad on his CBR600 back together.

-

Was going to fit and time the cams today, but the sun came out so I went to the pub instead.

-

Some where in the distance a bell chimes in the wind. A tumble weed rolls across the foreground and crickets start to chirp. A stranger rumages through a shipping container and finds a load of neglected projects. Hmmm suppose I better finish these. "There's a lot of parts in her that need anodising boy." New rear sets modelled and3d printed before committing to alloy. Rear brake disc assembled. Then stripped and sent for anodising. Along with some other bits. Mostly done in brown to piss off the hipster haters

-

I reckon 75% of the heads I've seen have those cracks. Never seen a failure from one.

-

Straight cut gears sap less power than helical, that's why race cars and most bikes use them, they aren't necessarily stronger. The helical gears on the F were used for refinement.

-

I'd optimise the ports and combustion chamber shape first, before going oversized valves.

-

15/48 works well.

-

Lighter weight and more simple.

-

Me neither. Griff's will sort you. Else I have a good man for stripping / powder coating bike stuff down here.

-

Re Powder coat removal. Blow lamp and a wire brush is you have patience. I'd avoid dipping as you'll never get tubes clear of the stuff. Blasting is a better bet.

-

I'm guessing 6mm. Drill lots of big hole in it to get the weight down. 4mm won't be stiff enough imho.