-

Posts

8,378 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by clivegto

-

Yes with ceramic beads then a load of chemicals.

-

The finish is extraordinary will be getting more stuff done, this was a bit of a test.

-

Been to see Brian McCall of Centuriion Motorcycle Projects today to pick my barrels & cams up. The barrels have been vapour blasted & the cams have been supper finished to make them slipper than a very slippery thing that is slippery (like GP gear boxs) will be doing gear clusters as well. He also has a very nice GS1000.

-

-

Thanks man. The harris supper bike yokes have a + - of 3mm off set, set them on the +3mm this should give me a bit more for the oil cooler, reckon I can get a 19 row one in there. Test fitted the new turbo there is a little wheel to turbo clearance but will move it further back, there's loads of room for this compared to my turbo scratcher.

-

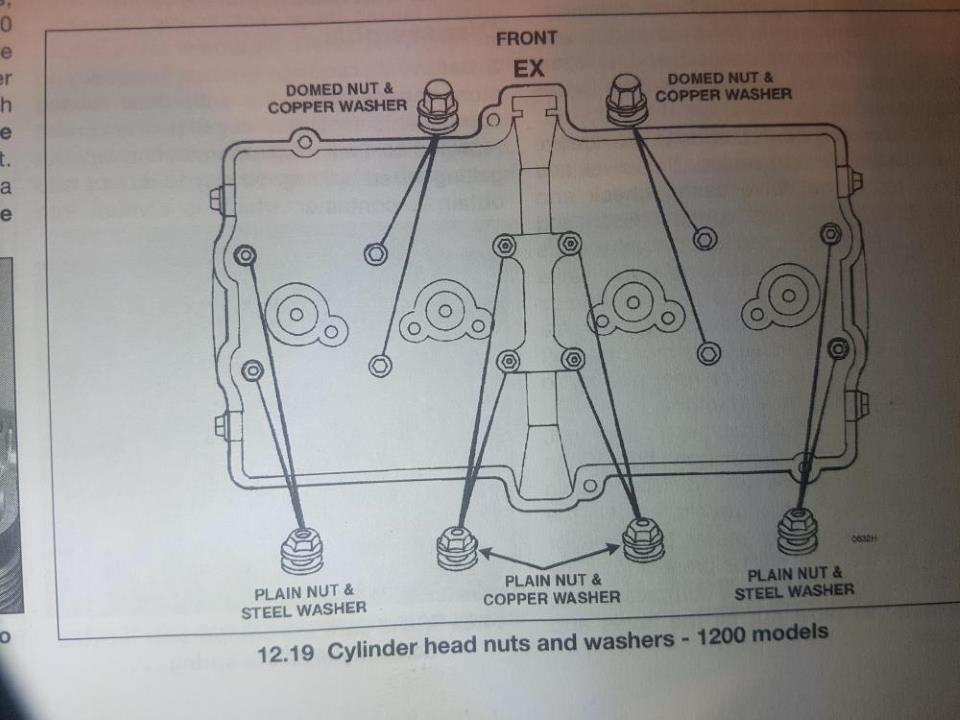

Pinched the Upperton flowed big valve head from my 1216 high comp motor I had under the bench for the Harris. Replaced it with a standard b12 head I knocking about. Timed it up & did valve clearances. Might put this motor in the Harris to get it running as the main motor build is not going acording to plan right now.

-

-

I can do that will probably be early afternoon before I can get there.

-

Acording to hel they are correct, will see a bit closer when I make wheel spacors up.

-

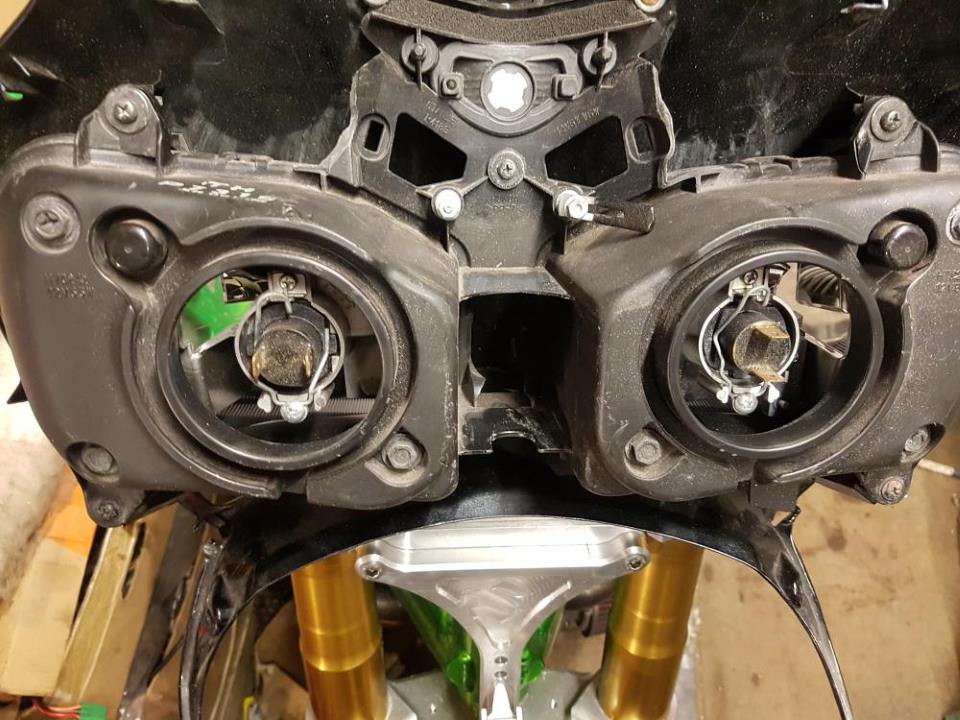

Drilled & tapped the bottom yoke for the faring/headlight bracket. Also made a bracket for the top yoke to mount it to. Countersunk the bolt holes for the main bracket. Little onda faring is what I am going to use, it is fully adjustable for hight & angle (touring or drag racing).

-

Oil coolers: branded v generic. Is the extra cost justified?

clivegto replied to Dezza's topic in Oil Cooled

I had problems with them busting on the Scratcher (turbo) went through about 3. Lot of vibrations through the braced 1986 gsxr 750 repaired frame. Solved problem by using Suzuki oil cooler rubber mounts rather than home made or direct bolt to frame at top mount like a lot of the after market ones. -

-

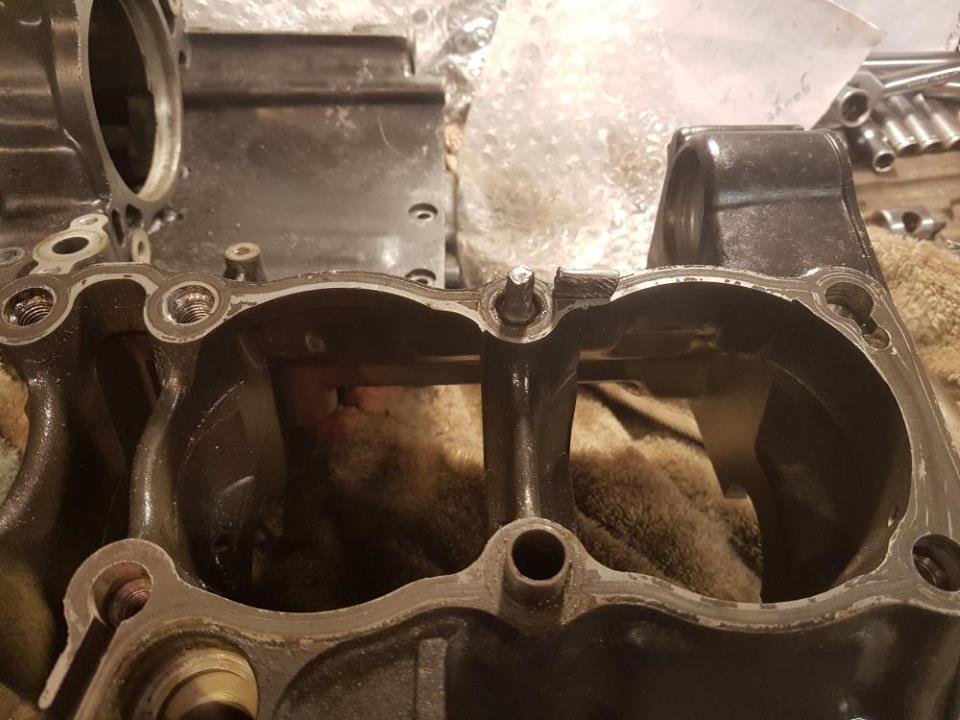

Bloody thing won't come out. Think the thread has picked up does turn a little back & forth. Weld won't take to it, cobalt drill won't touch it, will take it to machine shop & see what they say. On the bright side I am picking another bottom end up next week from Swirl.

-

Going to get the crank cases vapor blasted so removed the cylinder studs except 1 snapped twice. Am going to leave it alone for tonight before I damage some thing. Will weld a nut onto it tomorrow that should get the bastard out.

-

Look closer no rubber inlets for carbs is what I see.

-

What is going on with those inlets on the top one ?

-

Thanks, am really pleased with it.

-

-

I have a 1052cc motor with a ported dot head & cams ran 36mm carbs on it, goes like a screaming banshee lots of fun lol.

-

I call it the Turbo Scratcher handles like a dream makes 260hp. Head stock is braced, big cross brace on frame under the back of the tank & braced on the inside of the frame around the swinging arm pivot also has subframe raised by 50mm, frame mods were done by NWS back in the day. Think it was a endurance race frame in a former life. This bike holds its own with any modern super bike, it's just me that's getting a bit old lol.

-

Compressor wheel is 10% bigger than standard VF23. Am tempted to try it on my Scratcher but it is for my Harris build. Could always change the exhaust housing if not happy but it is going to be better than the td04l I have & like. You will have to have a go on the Scratcher @MeanBean49to see how it compairs to your Spondon.

-

Rob at fast line turbo's built me this it's a hybrid IHI VF23 p18 exhaust housing ball bearing core with a 46mm compressor wheel. Rob says it will spin up faster than a VF23 & make more power(350hp), very helpful man he was.

-