-

Posts

8,400 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by clivegto

-

-

They should be would make fitting them so much easier.

-

Fitted some bearings to the Harris adjustable super bike yokes to test fit them with a set of gsxr 1000k5 forks & k9 wheel. Looks like it will work alright to me.

-

Had to widen the inside of the arm to sink the arm bearing further in. Did it with round & round drill sanding wheels, made a guide up on the lathe to keep checking my progress. Then cut 10mm of the chain side of the arm to get it to fit the frame. Did scribe a mark round the arm to follow with the hack saw was only 0.3mm out so not to bad. Took 6mm off the sprocket side wheel spacor on the lathe, back sprocket is reversed which gives me 2mm & have the off set front sprocket. Wheel is central & chain alignment looks spot on.

-

Picked the arm up from the welders today. All looks good, it's going to be 50mm longer than a standard mag 2 arm with the 6 inch k9 wheel with the option to move it back another 130mm.

-

Think he is in New Zealand at the moment.

-

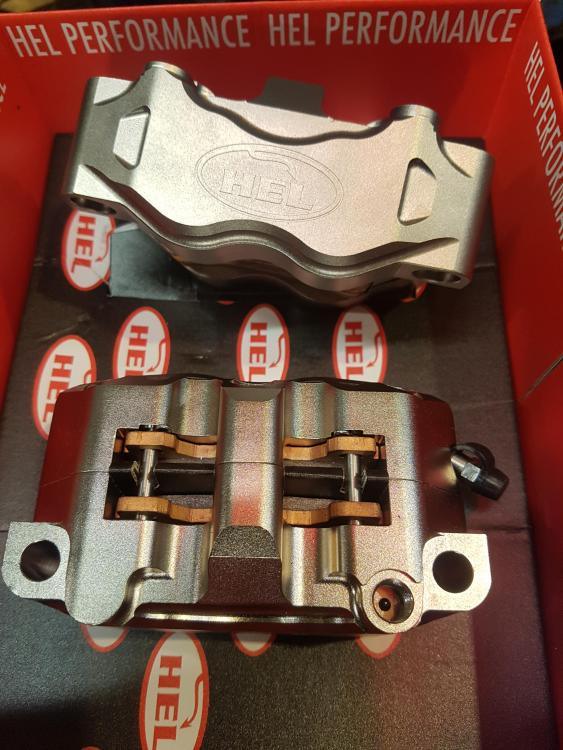

Show price was to good not to get a set, did walk away from the hel stand the first day lol.

-

What are my choices if I use a T2 turbo flange 72.3 x 40.6mm. Pic has a adaptor plate on but I don't really want to use that.

-

Some of you might remember my turbo b12 that has now been sat in the naughty corner for a few years. It has some nice turbo headers on made by Dave Dunlop. They are better design & fit the harris frame way better than the other set. 3rd pic is the set I am going to use (Daves). While I was at the Newark bike show with some of the other OSS boys I ordered a set of hel calipers, they turned up in the post today.

-

Count me in.

-

Was cool Oldskoolsuzuki cool.

-

Yes did it like that for room for a plenum.

-

-

It already has one mate.

-

Fastened it together with a jig to hold it in position while it gets welded up. Hopefully Will can weld it up for me this week.

-

Indeed it is mate & am having fun learning to use it as well but need to learn more. Happy New year everyone.

-

Can not do a lot with the engine at the moment so had a look at the back wheel & swinging arm. Wheel is about 12mm of centre & would not go to the front position on the chain adjusters because the tyre was hiring the arm on the right. Hey ho cut it in 1/2 againe made a spacor up on the lathe. Looks like it will work now.

-

Yep.

-

Strangely enough on tick over it reads -6 & I have never seen it above +8. When I had it on John Warrington's dyno we pipped his big gauge that is fastened to the wall onto the bike. It measured 15.9 psi on full wack. Pic is of bike on tick over 950 revs -6psi.

-

No you don't need it I just thought it would be Intresting.

-

-

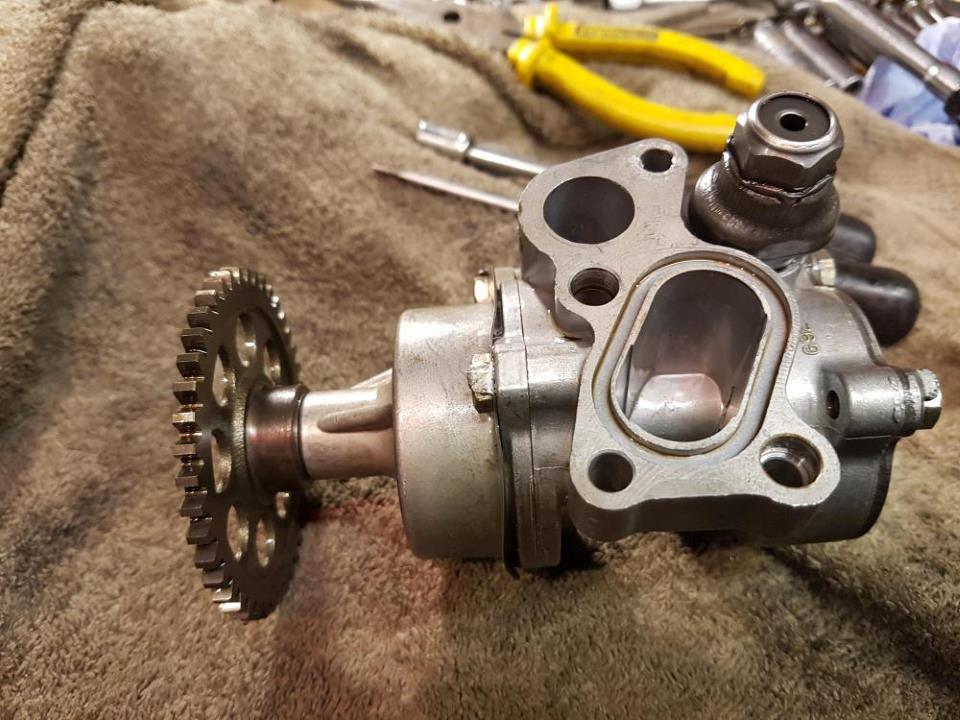

Not done any thing with this for a couple of weeks been fitting a JMC swinging arm to the turbo scratcher & Christmas got in the way a bit. (Lots of beer). Tidied the workshop up a bit as well can now move round in it. Took the oil pump of for inspection, all looks good so put it back together againe. Have ordered a impact driver & a stud extractor to help strip the rest of the motor down.

-

Was told 270hp was about the max out of a tdo4l.