-

Posts

8,317 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by clivegto

-

Got a nice looking little Facet fuel pump with a built in fuel filter and An6 fittings today. Plan is to fit it under the seat.

-

All balls do quit a few bearing kit conversions.

-

As said change crank & clutch. I wouldn't bother personally I plan on building a turbo F motor. Others on hear have gone over 220hp without any problems. Only thing is the 2 side ways thrust bearings on the crank will wear out slightly quicker.

-

Mk2 cams are slightly wilder than mk1.

-

There the same colour as the barrels & back caliper.

-

Not exactly, the wild man that is@Dezmeister gave them to me. They are pens that have paint in them.

-

Bit expensive to cut up if it goes rong. Would be interesting to see inside one.

-

Brian McCall called in today as he was in the area with my clutch and sprocket covers. He has aqua blasted then painted with his special ricochet pait which is petrol, brake fluid and heat resistant.

-

Got the huge b12 lithium ion battery to fit in the undertray by trimming a bit out of the subframe, plastic undertray and back seat catch bracket. Just needs a bit of thin foam to sit on now.

-

There are 2 different size taps for slabby tanks.

-

Made a bottom for the boost gauge pod from some 12mm aluminium flat bar. Cut a bit of then spun it down on me little lathe. Drilled 2 holes to fasten it in the pod & 1 for the pressure pipe. Wires are tucked inside for now until I deicide where to route them. Also need the main clock's fitting which I have not got yet before fitting the boost gauge.

-

Yes it works with air & has a back light.

-

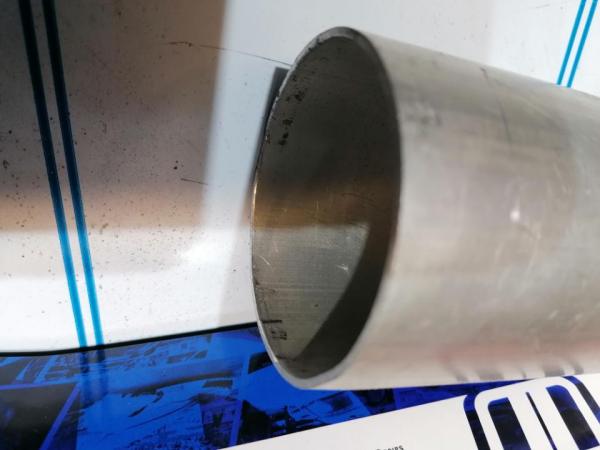

Decided to use a turbosmart boost gauge which arrived today. Started to make cover for it from some 2 1/2 inch aliminium tube. Swaged t one end inwards with an adjustable rench & me trusty hammer then spun it in the little lathe to clean it up with some emery cloth. Still needs somat to fill the bottom as well as a bracket to stop it falling off.

-

Am in two minds whether to risk using the smaller one but space is limited.

-

Got a r1 lithium ion battery for the Turbo Magnum which has 144 cca. Tried it on my other turbo bike & it started up from cold but only just but its tichy even compared to the smaller than standard b12 one I use on the Turbo Scratcher.

-

Just swap the cam wheels over, the 1052 cams have more top end power.

-

Got a aluminium tail to go on the bottom of the oil tank to fasten a drain pipe & bung from a b12 airbox to drain the tank easily. Painted it with lidle gloss black.

-

Will welded the oil catch tank up for me. Window glass & some m16 dowty washers turned up as well as 30° torques_uk fitting.

-

-

Are those teeth at a angle or straight, I cannot tell from the picture.

-

I thought the gsxr slingshot stem was a bit to short when I was fitting k9 forks & yokes to the Magnum 2, but @caferacerdanfitted one to his Magnum 2. I used a b12 stem which is a little longer. Moved the C clip groove up the shaft a bit knurled it as it's a bit slack then made a spacor to go under the top yoke to take the slack up. Ended up fitting K5 forks with Harris adjustable super bike yokes. It's in the thread Swirls Harris what I did.

-

I bought a adjustable stem from Harris for my Magnum 2.

-

You need to measure the clutch plates & build the correct height for the clutch stack, gsx1100f clutch plates are the same as the early Gsxr1100 slabside models. Try Robinson Foundry for parts with the 5% OSS discount.