nlovien

Members-

Posts

622 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by nlovien

-

believe an ignitech ignition can be programmed to do this - i.e. you spin the motor 1st with no ignition then trigger it as the engine is turning - you can obviously achieve this by flicking the kill switch after you start spinnig - well known technique to help a weak starter drive in another type of engine note of using HT bolts: don't recommend over torque - they are more fussy than std bolts - over torque HT bolts and they are more prone to shear - seen it happen

-

time spent getting a tired set of valves back sealing properly + setting the squish up properly then dial in the std cams - playing around the 105/105 to 110/105 range to find yir happy range focussed cams can end up costing a shit load more than the cam itself - typically means there is more HP but at the bequest of more rpm - and more rpm likes things like underbucket shims - lighter valve bits, maybe better valve springs - sometimes better rod bolts or even new rods, then you be as well lighten the crank - are we over a grand yet ? big bore always provides from zero to redline so if its just one thing without incurring add on bits to make it work then big slugs win - spend on selecting a trusted company to bore it for you - the down side to a big bore kit is a cowboy machine shop - and - again, get the squish right via headgasket selection after decking the pistons to the block - i.m thinking ( needs confirming !) 0.040" squish for these motors ???

-

back to your original issue - learned this from too many times assuming - 1st thing I now do is take swing arm off and place the pivot shaft and wheel spindle on matched blocks - basically if it doesn't sit solid at each x 4 corners then its bent beyond use ( couple of mm here can throw out the wheel contact by over 10mm ) - it also throws out the sprocket alignment checking the frame itself isn't easy without making up stuff but you can go a long way by amplifying the two key points - steering stem to swing arm - are they perpendicular to each other ? - stuff a long piece of tube through the headstock and swing arm pivot points - not accurate but a half decent eye ball - recently showed a friend his frame was twisted by doing this - mind you, it was for one of them american cycles, their probably all like that

-

aye - old codger making good progress up the M1 spots the flashing blues approaching - opens her up to try n get away but the blues keep getting closer - dam't he thinks i'm just to old for this these days and decides to pull over Well says Mr plod - that was a fair lick of speed you got up to however i'm in a good mood and if you can give me a good explanation for your reckless turn of speed then I may consider a warning this time I'll not tell a story officer - i'll just tell you the facts - about 20yrs ago my ex wife ran off with one of yir mates in blue - - - - - - shit I thought you was trying to give her back

-

reason why I don't like anti dive ? dam't near shat myself the 1st time I tried getting into a corner whilst hard on the brakes - can really negatively affect how the bike wants to turn in - would like to think any worthwhile article on this covers this inherent trait of this device - for me ? thing of the past - at best an elastoplast for other issues, more likely a failed marketing ploy in an attempt to bring a forgotten racing thing into mainstream

-

staples or alloy rivets work fine along with an impact adhesive - also consider a layer of plastic ( bin bag etc..) between the seat foam and the outer material - helps reduce the seat becoming a sponge given the seat material typically used is porous

-

to go onto that i'd take a fibreglass mold of the seat base to use as the base for the seat pad - if you've got room adding a separate back pad place cling film over the seat - slap on a coat of resin + a few layers of fibreglass and hayho - 30 minutes later there's the perfect shape once you've got this base cover it in clingfilm and spray expanding foam onto it so you can easily make a dummy shape of how you want the seat filler to be if you want more of a raised / curved seat versus a flat one I find it better to add this shape via more fibreglass versus bulking out the seat filler

-

I suspect part of the reason the short filters with back plates cause issues is because the back plate is too close to the carb - you might try fitting a venturi extension then the K&N's - i.e. there could be a bit of early mid range tuning benifit to keeping these type of filters but at a longer length from the carb

-

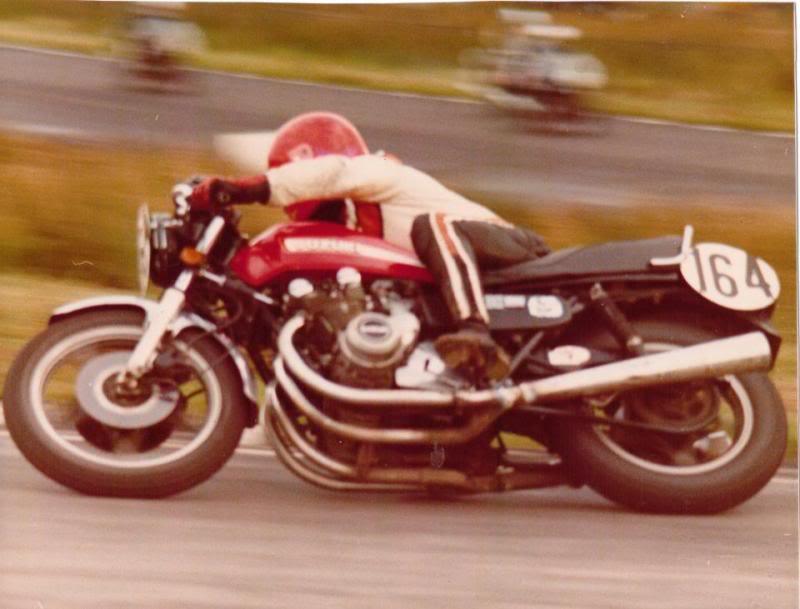

thats a few pretty unobtainium parts on that bike check the float on the front disc bobbins that will give you an idea of just how much miles its done ( i.e. if they are tight then not a lot ) - given the previous owner has fitted this level of noticeable parts - any suggestion that the engine / carbs / igntion has been worked on ? - your on your way to a classic race bike there be there when the guy removes the tyres - take the opportunity to inspect the mag wheel rim of any major pitting - just in case the outside is a tidy up and respray job hiding what maybe previously corroded wheels and forsure use them on the road, just remember to stop and inspect if you do hit a pot hole etc.. - i've split two of them on the road, they are fine but they are not as forgiving as road alloy ones

-

ref: carb size - had this discussion with racers / tuners - new school and old school and i'm dam't if I can nail down an agreed consensus of opinion based on result - summary is - especially as you've gone to effort of porting and cams - you'll likely be chasing rpm = new school response - go as big as you dare ( use your inlet port entry size as a guide ) old school will tell you go the opposite = as small as you only need to go, it will be more efficient at part throttle, easier to tune ( or read as more forgiving if they are not right on tune ) - ok so no answer for you my own experience ( was old school) is modern flatslide smoothbores are mucho better at partial fueling these days - i.e. go big CV versus directlift smooth bore - if its performance then 100% the smoothbore pumper - maybe not if you only look at the top HP but the initial punch / drive / throttle response - no competition ( and you can gain on mpg as an added bonus ) if its good performance with a smoother lazier pick up, lighter throttle etc.. i.e. the stuff that makes mile crunching on the road more pleasant = go CV

-

the other bit - not often discussed but important is the turbo body size ( the throat ) - one to watch out for when you go looking - bigger CC engines may have the same compressor / turbine wheels but have a bigger throat ( housing ) - go small on this and you'll get improved early spool, go too small and you'll choke top end, conversely go too big and you'll be waiting all day for spool up = previous ref: to +/- 2litre car engine a small throat with a bit of porting to max the flow to the waste gate is a good balance i.e. so you can bleed past the turbine as the rpm rises to reduce choking = this leads to another tuning tweak = how and where you introduce the WG flow into the ex pipe downstream of the turbine exit - get this wrong and the two flows clash causing back pressure, get it right and the WG flow can help scavenge ( lower the turbine downstream exit pressure )

-

from my exploits with tuning old saabs = two routes 1) sledge hammer approach - boost is king = big bang, good for wahoo effect in a straight line - pain in the arse to manage otherwise and typically loses much bang with heat build after a few slugs 2) jeweler's screw driver approach - use as little boost as possible and tune the cams / ignition timing / fuel injection to suite = a smoother more turbine effect that will deliver with controllable demand all day long - get this right and you can have more top end HP with less psi ( ref reading a turbo chart - look to the RH side - you can see how once you get to the limits more boost doesn't provide more HP so it just spins the compressor faster creating heat ) - - other note is cam timing can make a noticeable effect on the initial rpm you get usable boost at a price - time for early boost = loose top end // time for top end and you induce more lag experience with the saab turbo's the Garrett GT25 will marginally beat the Mitsubishi TD04 on early spool, the TD04 will marginally beat the GT25 on top end - std the GT will see about 280hp, the TD04 about 300 ( note you can find the turbo specs for these cars via SAAB forums etc.. but look for the 9000 tdo4 versus the 9-5 it has a larger turbine if you want to max these out, fit a gt28 compressor to the TDo4 - it works much better than the mitsubishi 19T upgrade - this is what the left hand side of the graph shows if you compare a gt28 to a 19T, the garrett compressor delivers as it spools up, the 19T struggles until its up to speed - with the GT28 compressor on a SAAB td04 + cam timing shift bias to top end I got over 360HP (1.3bar boost ) overall = for the older car turbo's - from my experience, the Garrett GT25 is a very good all rounder with early spool, easy to tune and forgiving when its running outside optimum - the TD04 will give you a bit more, if you can use it but it takes a bit more work to find it and its more focussed ref rpm range

-

take a look for signs of oil - maybe a leaking valve seal / worn guide causing contamination signs of the piston crown being obviously muckier / wetter than the rest - crud build up at the bottom of the inlet valve etc..

-

as yir asking - not so sure myself, at risk of it looking like a parts bin special with too many bits obviously from trade mark bikes - getting them to work together will be a challenge great project - liking the approach , although a well tried and tested combo - my thoughts would be more along the lines of an Eddie Lawson / Wes Cooley style cockpit -

- 75 replies

-

- gsx1100

- gsx1100efe

-

(and 1 more)

Tagged with:

-

linseed oil etc.. works fine, the inhibitors are good - ref: acf50 - some of them tend to stain the metal with a phosphate coating - can look a bit yeucky hence using just an oil - the chromoly will pit rust just from the smell of a wet fart

-

on the point of the CV carb drinking petrol versus the direct lift - yet HP figures +/- same HP figures +/- same suggest at WOT either carb is being efficient in supplying what's needed for the given engine tune = important on a race engine that will spend time at WOT, not so important on a road based engine which spends not a lot of time at WOT, yet we often calibrate our carbs to the part that we rarely use the bit from closed to WOT is where the road engine lives - direct lift carb we tune each primary fueling circuit with a direct relation to throttle position - on the CV its a bit of unknown as to what circuit is actually providing the juice at any given engine load other than WOT - if your drinking a load more fuel then - for me - it suggests your wetting out - possibly because the vacuum control of the slide lift is now out of sync with the engine demand ( and adding back the airbox can help to bring this back into sync ) - but the area that needs focus is the rate of slide lift via return spring and slide lift holes trying to picture this direct lift - easy you can see the slide lifting in direct relation to demand - fuel from here - now fuel from there - thank you CV - I can picture, large throttle opening followed by the slide going through a fluctuating cycle from closed to full open until it finds the balance and whilst doing this its slugging fuel into the venturi versus accurately metering it - so maybe slow the slide lift response down - i.e. damp down the fluctuation - but over do it and it will not lift quick enough, or hold open at WOT - -- basically consider when tuning CV carbs that the slide lift response is as important ( maybe more so ) as the jetting - not something you consider with a direct lift, and hayho - any CV carb tuning kit i've seen does indeed include mod's for the slide lift - not saying the kits get it right though! problem is - so where do you go for a range of carb slide springs ? - ok so focus on the lift holes

-

not heard of much these days ref: self exiting generator parts - but given the damage, the balance - i'd be avoiding the possibility of these things breaking up at 9K rpm

-

ok - now i'm seeing more bits, that's more like it - blingtastic to infinity - and beyond

-

not enough though, this is beyond bling

-

good stuff, going to really appreciate your feed back on how you set it up

-

i'm a yr or so away from getting my modified magnum 3 on the road ( the mag 3 is close to the F1 chassis) your welcome to try the front end on it - as an option to help direction - should be a bolt on job - coupled with a bit more rear ride height + shifting the engine fwd ( your is about as far fwd as you can get ) it changed how the bike worked a lot! for the better Its the 45mm fireblade fork front end tweaked by Maxton c/w the wide profile 16" front - don't recall offset / trail but it manages the magic sweet spot of feeling like it will turn on a sixpence yet behaving very planted and stable ( not needing a steering damper ) - on the rare occasion it would shake but self correct before you think of it - this needed something like a rippled up inside corner to set it off - its a bit shorter than what was on the bike - again this adding to the front end biased feel anyway - if its any use to you as a test - no worries - all you'd need is a fresh tyre on it

-

be great having a decent rider document the chassis set up / build - be interesting to see if you prefer it - old school, stable but a bit slow on the turn on big wheels, or more modern - weight pushed fwd - quick steering response, smaller wheels etc..

-

on the mikuni RS carbs - the throttle return spring has x 3 different holes for preloading and hooking the spring tail onto - use the hole that requires the least amount of tension to get the tail into it another area = play with the throttle drum cam shape - if you reduce the diameter = longer throttle pull to get to WOT = less stain ( its like a gear ) - down side is if its too long yir wrist is in the wrong position - ok for a straight road but crap for corner exit etc.. - if the cam diameter is too big - great a quick action throttle but its more strain - there's a sweet spot between the two that can be be found by starting with a quick action diameter and filing the cam shape down ( doing this to match the carb torque sweet spot to yir wrist movement is worth a load for free especially in corner exits )