-

Posts

5,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

1500 miles !!! - a month !!! - luxury. When mapping mine on the dyno, the guy phones me up and says we need a new tyre - why says I thinking its punctured!

Cos its melted says he ! ! ! LOL Brand new Bridgestone + 370hp + twin roller dyno = 2hrs life! Oh how we laughed!

-

1

1

-

-

Yes use sealant - Gaskacinch is what i'd use - its like thinned out, non adhesive Evo-Stick and it works!

-

1

1

-

-

Sprinting ain't so different to Drag - just piss poor tracks usually LOL! So I question a raked out front end and a strut rear end - that's very 80/90's style. Wisdom has moved on where the quickest in the world mount EVERYTHING possible over the front wheel, with the forks pulled in to steepen the rake and use a long arm and a proper shock to deal with the launch and short track reaction. If you haven't got bars the MTC slider isn't the easiest thing to tune as it has to slip loads more than its design likes! What Schnitz box? Pro2's are / were the flavour of the month in Comp and ProMod - they aren't renowned for reliability so most would have a spare! If swapping to a Dyna your still gonna need a nitrous controller which the Pro2 does really well IMO!

-

Don't forget import taxes and vat that get added on by the freight co. on behalf of the Gubmint!

-

The radius on the plates teeth is from the stamping process and it makes no difference whether flat side in or flat side out as it'll only be 'correct' 50% of the time - clutch lifted / clutch released!

-

1

1

-

-

The std 750 flatslides may be a bit restrictive although plenty of people have bored them out to 33mm to release a bit more airflow but compared to the 38mm CV's fitted to the DOT head models, i'd say they'd come up short. I'd imagine 36mm Flatties would be the best compromise between mid to WOT power on a 750?

-

I know Sean well and all through the 'Phil Wood' years with the Spondon Kat and he could never manage it then even using a 48mm version HSR (from memory) so don't know what will have changed? A rising rate FPR is usually a bit of a 'band aid' on EFI systems - never heard of a successful use with carbs. I'm guessing that dealing with non linear fuel pressure plus addition of boost pressure will give moderately unpredictable results?

-

2 hours ago, Stephtell said:

LOL

Thanks for that! I thought it should improve things somewhat, glad to have confirmation on that!

The previous owner couldn't get the HSR to deliver enough fuel for 300 BHP, hence fitment of the S&S but as far as I'm aware 300 BHP should be no problem for the HSR?

B.t.w. how did you get to 1460cc??

There isn't a snowball in hells chance of any HSR fueling 300hp! The float bowl is massively too small and pressure needed to fill it and keep up with demand is so excessive that it floods at anything other than mid range and up! 250 'ish hp with nitrous assist is about the only way i've seen of getting close!

If - as the other poster noted - it is a Rajay........it'll never flow enough air even with F flow bits - Sorry!

1460cc ? piece of piss.................... M O N E Y !

-

1

1

-

-

Compared to the S&S tractor carb, you could mount the HSR, up on the headstock and response would be improved! Wherever it fits and looks ok, is fine!

-

1

1

-

-

Onward - and upward!

Its a learning curve but soon you'll have Guru status!

-

Depends on use! RS38's offer good all round usage (or 39mm FCR's) or 40's for all out racing (or 41mm FCR's) if you've got the airflow and compression to use them.

If your loaded? then 38mm Miki TMR's could be the ultimate................for carbs that is! Having discovered practicalities of EFI - that would be my personal choice!

-

2

2

-

-

I may be simplifying things but if you'd mounted the ECU why did they take the bike apart to add a hook-up lead? Why move sensors if you positioned them sensibly and where you wanted them? Its not about mis communication - its about ineptitude! Mistaking a engine breather for a boost hose is fairly basic error by someone who either doesn't care or can't be bothered to care! They've likely lost any repeat business with the OP but what about others that don't know and get treated the same - i'd be fairly pissed if I could have been forewarned!

-

1

1

-

-

Can't recollect any aftermarket turbo pistons being made that small ! Any markings on the underside? Just checked my APE catalog and Wiseco did a 76mm Turbo slug 7.8:1 CR so loads of boost potential!

-

That is a reasonable list to get shirty and shouty about. Know its early doors but a name might be useful - if only to be wary / avoid?

-

Master cylinder bore size of the ZX9R compared to the GSXR variety must be playing a part and / or lever ratio which will influence amount of fluid moved which seems to be insufficient! Worth checking?

-

Personally I ran a catch tank ( but was racing as well so better to have a recirc catch tank and not oil the track after forgetting to empty the can!) This is based on the fact that a tank will need the same amount of vents as are run to it..................i've seen tanks with 3x lines in and only 1x 12mm K&N to vent - it just don't work!

-

Why does this MYTH of 'needing a bit of back pressure in an exhaust' persist? It may make the engine a bit more tolerant on the jetting selection, but only because its not working efficiently. I've never known anyone who goes seeking max power say lets throw a silencer on if they didn't have to under regulations! Hey we've got a 10,000hp Top Fueler, lets add an Acropovic and see how she goes? Its FANTASY - back pressure is bad - period! Turbo's create massive backpressure in an exhaust hence lower outputs off boost - its just that the boost over comes the restriction but its still a trade off!

-

1

1

-

-

Think of it this way - you are trying to drain oil by gravity into a pressurised tank (the crankcase) without adequate breathers! Turbo's need breathers and as many as you can fit / as big as you can manage. I didn't consider 2x dash 10's and 2x dash 8's to be excessive!

-

1

1

-

-

Beautiful curve G1460, I'm a big fan of the 1100 M/N head, if you're not planning to add hairy cams of course - they flow well and are designed to work with the big 40mm cv carbs - of course it could be your DIY exhaust !

Agreed, M head is a good 'un but this was using 36mm CV's - a nicer carb to work with. The exhaust was built 'to the bike' and did have longer primaries than usual - maybe a 1/3rd longer - and I think that was what was responsible for the torque! I should have tried it on my 1460 - that would have been a hoot!

-

Alot of oil can linger in the snail, or even drain back down from the turbo coating the inside of the up pipe and pooling in the collector, this being the lowest point of the exhaust. So one event of oil passing the seals can have on going simptons. The only way to trouble shoot is unfortunately to strip all the exhaust off ,clean, re assemble and test again. Very tedious indeed lol

Don't agree with pooling in the up pipe! That is the hottest point (around the collector) and any oil would be burnt off and the thing would be smoking like a Steam Engine! I'd say, looking at the clean oil, its turbo seal related - either fubar'd or badly fitted? You said you are using a dash 10 drain - is it horizontal anywhere or vertical drop throughout? Its possibly backing up in the pipe and overwhelming the seal?

-

Having a hard time imagining these two, pics pretty please Gixer1460

Plus, has anyone tried a weld-on location in the top case? Some where above or behind the transmission i'm thinking.

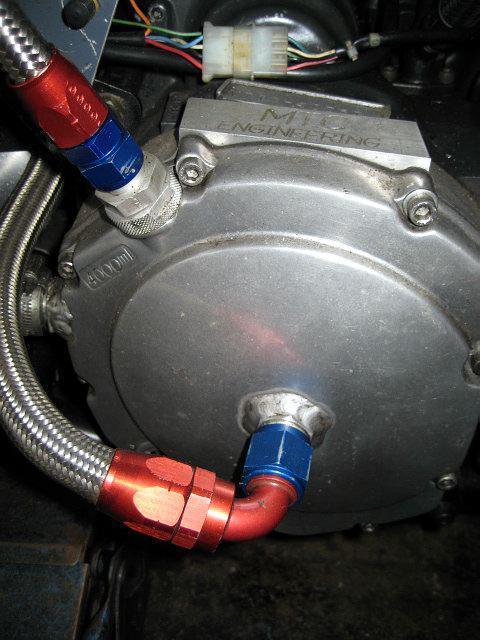

Re the Weld-on Q - the red cap in the 3rd piccy was the dash 12 turbo oil drain line return - not into case but into clutch cover

-

1

1

-

-

The longer screw has likely punched through the casing into an oil way or drain hence the leak, so welding is the ultimate fix. I've used JB Weld on heads before without drama.......this isn't directly exposed to 900 deg exhaust temp, probably nearer 200 - 250 so should hold ok for a fair while providing the area is well de-greased / oil free!

-

anyone have them in a size that's legible? when I enlarged it the numbers weren't clear enough to make out

Whats wrong with the 'GSX Laser' drawings below? Click on them and they open fine for me?

-

Big bores and forced induction motors will all suffer ring blow by and crankcase compression - fact. Without increased breathing, you'll end up with blown seals and leaky gaskets - fact. Any added is a good option - my 1186 turbo had oil filler vent in dash 8, clutch cover vent in dash 10, std cam cover vent in dash 8 and additional cam cover weld on in dash 10 - excessive? maybe, but never blew a seal / gasket ever.

Copper head gasket, oringed cylnder and dry blocked. Sealant??

in Oil Cooled

Posted

That's the best bit - don't spoil it!