-

Posts

5,444 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

There's nothing wrong with a GSXR / Blandit bottom end - it how they get treated that kills 'em. If you over-rev them ie. consistantly over 11,000 you'll snap them, excess revs + other areas that lead to oil failure will also kill the big ends and will usually take the crank pins out as well.

250hp was generally taken as the rod limit when using nitrous - turbo's are softer on rods but 300 is probably the upper limit as you don't rev a turbo motor......there's just no need!

-

1

1

-

-

More words in explaination...... Comp ratio ie 8 (ie 8:1) multiplied by boost max used in Bar ie 1 bar = 14.7psi plus the CR ie 8 again, all must be equal to or less than 16...... so you get ........ 8 x 1 = 8 + 8 = 16. so that would be ball park. Lets go more extreme........ 7 x 2 + 7 = 21 so could be too much.

Personally I think that formula is a bit conservative as using my own build numbers I get ........9.5 x 2.5 + 9.5 = 33.25 which is definitely the wrong side of 16! Now maybe I got lucky but don't think so. One question is - are you using carbs and normal ignition or EFI and engine management?

I believe that the former set-ups cannot control fuelling / ign. timing accurately enough to get the optimal performance out - the latter allows better control without random fluctuations that cause detonation and engine failure.

Very few get it bang on right first time - its just how badly its wrong that makes or breaks a build.

-

Would be a near stock swop - virtually no mods required except jetting!

-

See here...... http://kryptracer.com/Camshaft___Valvetrain.html

Very informative and quite interesting. Make sure the Cams are G21X and G28X as they are different to G21 & G28!

-

1

1

-

-

They'll work fine - just be careful on the mounting as its easy to short out the screwed connections!

-

1

1

-

-

Do you really need ignition and fueling features though? why not just a standalone fueling ecu? i have a microtech that i used on a bike that was fantastic, it might even do both actually but not sure as i bought it used but i will be selling it cheap soon if any use to you mate?

If you need to add an additional toothed wheel for the EFI (and on anything more sophisticated than a squirt of fuel every firing stroke, that is advisable) then why not - mappable ignition is worth as much as correct fueling especially with forced induction - just cos contact breakers work doesn't mean they are a sensible option?

-

Yeah but John you haven't used any real power yet ! LOL

If you can make a pass with a 2 or 2.5lb bottle yer still only playing

-

750 = 22 / 23cc and 1100 = 26 / 28cc Ring a bell in my melon hence the 750 head compression increase with just a swop,

-

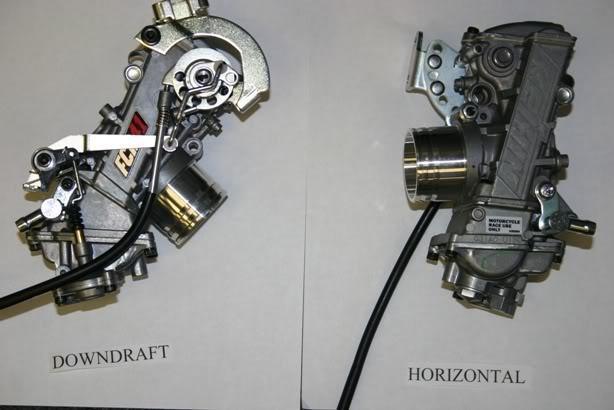

Re Divider plate - would depend on where the injectors were placed. Used to be common with a carb set-up, that the air flow would swirl in one way or the other

and fuel distribution would go to hell - even with - it wasn't brilliant!

Have you any photos of the injection / plenum set-up as I was working on an injection plenum for my old draw through but never finished it, As it originally

used a 2 1/4" S&S, I was going to use a BMW 60mm TB where the S&S was. Strange with the Microsquirt - haven't heard of many reliability issues with them

- was it DIY build or bought in? Big shame as its a promising looking project!

-

If you're such a fucktard you're not capable of remembering to kick the stand up before buggering off, you should probably take up another hobby, like wanking or being a copper.

Not sure if that's aimed in any particular direction ? But pretty sure we've all ridden of with the stand down once or twice and / or tried to start in gear?

-

Pssst - the oil drains are at the front of the engine!

As Ben Slabby says but that is providing you havens got all the sidestand / clutch switch bollux still in circuit as this one runs through them to varying degrees

to 'save you from yourself' if your stupid or forgetful!

-

Those would work and may give a little boost whilst retaining the bottom end but if you want more - you need bigger - simple physics!

36 CV's is usual choice but good used sets are getting thin on the ground - RS36 flatslides would be about ultimate for daily driver / stump puller!

Keep the stock carbs (if tin tops) for the turbo!

-

F**kin' hell Phil - try and at least give us a clue - what Bike, engine, colour of wire? We're not telepathic!

-

1

1

-

-

How "quick" is your intake air temp. sensor? and is there intake air temp correction?

If the iat sensor is slow and it warms up when the boost is up, the iat correction leans the mixture.

Change the iat sensor to quicker or disable the iat correction (if there is).

Same train of thought I was thinking! I like the Bosch IAT sensor with a cage around the sensor thermistor - fast reacting unlike the brass encapsulated types which are better for water or oil temps.

Plus increased intake air temps will increase overall engine temps to a greater or lesser degree!

-

Two inlet cams in Busa motors used to be a hop up tip back in the day - so why not give it a go, just make sure you have decent piston - valve clearance (1.0mm) if pulling big revs!

-

Agree with that I have done most of the above swaps! 1052 bottom end with b12 cylinders on opened 1052 cases. 750 dot head skimmed by 0.005" upperton flow job stg 2 yoshimura cams. Made 147bhp. 86lbs torque + With micron gsxr 1000 headers !

Just get swapping Frankenstein motors are awesome fun.

You did all that for 3hp more than this - 1186cc, std M head and cams, CV carbs and a DIY 4-2-1 pipe.

-

2

2

-

-

-

On the up side.......at least the crank and rods should be salvageable.............ok! i'm getting my coat!

-

They are and the spacing at 86 - 92 - 86 is way off!

Sorry - walk away from the dark side

-

As the needle never completely leaves the tube it will have an effect - the MJ basically governs overall fuel flow whilst the needle regulates throughout the range. Do a plug chop whilst riding where is roughest to give a steer on whether fat or lean

-

That would depend to a degree on how bad someone wants it and what size Rajay ...it is ....

And type and if it has the right bits on it!

-

1

1

-

-

No it doesn't John - throw the phone away!

-

-

The problem is gonna be what size is the sender? The suzuki cap screw 'cover' is M14 or M16 and once you bore and tap the centre out

you can't tighten it! May be easier to swop it out for a normal hex bolt and a dowty seal / washer and put the sensor in that?

Turbo charging my B12

in Forced Induction

Posted · Edited by Gixer1460

A scavenge pump isn't necessarily required - all depends on how well you fabricate the exhaust manifold! Get the turbo high enough and gravity drain is still practical. Personally i'm not a fan of electrical suction type pumps and use a mechanical, crank driven scavenge - always there, always working. Also budget for a decent ignition as a weak spark will not light a boosted cylinder!

AFR gauge - Wideband Lambda - damn near essential for tuning etc.