-

Posts

5,446 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

That is a reasonable list to get shirty and shouty about. Know its early doors but a name might be useful - if only to be wary / avoid?

-

Master cylinder bore size of the ZX9R compared to the GSXR variety must be playing a part and / or lever ratio which will influence amount of fluid moved which seems to be insufficient! Worth checking?

-

Personally I ran a catch tank ( but was racing as well so better to have a recirc catch tank and not oil the track after forgetting to empty the can!) This is based on the fact that a tank will need the same amount of vents as are run to it..................i've seen tanks with 3x lines in and only 1x 12mm K&N to vent - it just don't work!

-

Why does this MYTH of 'needing a bit of back pressure in an exhaust' persist? It may make the engine a bit more tolerant on the jetting selection, but only because its not working efficiently. I've never known anyone who goes seeking max power say lets throw a silencer on if they didn't have to under regulations! Hey we've got a 10,000hp Top Fueler, lets add an Acropovic and see how she goes? Its FANTASY - back pressure is bad - period! Turbo's create massive backpressure in an exhaust hence lower outputs off boost - its just that the boost over comes the restriction but its still a trade off!

-

1

1

-

-

Think of it this way - you are trying to drain oil by gravity into a pressurised tank (the crankcase) without adequate breathers! Turbo's need breathers and as many as you can fit / as big as you can manage. I didn't consider 2x dash 10's and 2x dash 8's to be excessive!

-

1

1

-

-

Beautiful curve G1460, I'm a big fan of the 1100 M/N head, if you're not planning to add hairy cams of course - they flow well and are designed to work with the big 40mm cv carbs - of course it could be your DIY exhaust !

Agreed, M head is a good 'un but this was using 36mm CV's - a nicer carb to work with. The exhaust was built 'to the bike' and did have longer primaries than usual - maybe a 1/3rd longer - and I think that was what was responsible for the torque! I should have tried it on my 1460 - that would have been a hoot!

-

Alot of oil can linger in the snail, or even drain back down from the turbo coating the inside of the up pipe and pooling in the collector, this being the lowest point of the exhaust. So one event of oil passing the seals can have on going simptons. The only way to trouble shoot is unfortunately to strip all the exhaust off ,clean, re assemble and test again. Very tedious indeed lol

Don't agree with pooling in the up pipe! That is the hottest point (around the collector) and any oil would be burnt off and the thing would be smoking like a Steam Engine! I'd say, looking at the clean oil, its turbo seal related - either fubar'd or badly fitted? You said you are using a dash 10 drain - is it horizontal anywhere or vertical drop throughout? Its possibly backing up in the pipe and overwhelming the seal?

-

Having a hard time imagining these two, pics pretty please Gixer1460

Plus, has anyone tried a weld-on location in the top case? Some where above or behind the transmission i'm thinking.

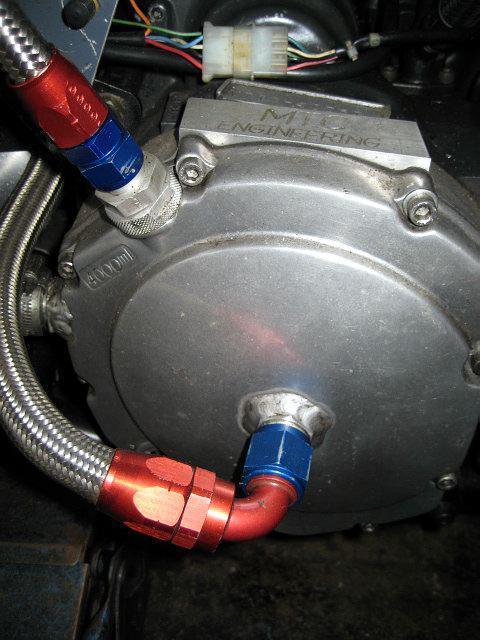

Re the Weld-on Q - the red cap in the 3rd piccy was the dash 12 turbo oil drain line return - not into case but into clutch cover

-

1

1

-

-

The longer screw has likely punched through the casing into an oil way or drain hence the leak, so welding is the ultimate fix. I've used JB Weld on heads before without drama.......this isn't directly exposed to 900 deg exhaust temp, probably nearer 200 - 250 so should hold ok for a fair while providing the area is well de-greased / oil free!

-

anyone have them in a size that's legible? when I enlarged it the numbers weren't clear enough to make out

Whats wrong with the 'GSX Laser' drawings below? Click on them and they open fine for me?

-

Big bores and forced induction motors will all suffer ring blow by and crankcase compression - fact. Without increased breathing, you'll end up with blown seals and leaky gaskets - fact. Any added is a good option - my 1186 turbo had oil filler vent in dash 8, clutch cover vent in dash 10, std cam cover vent in dash 8 and additional cam cover weld on in dash 10 - excessive? maybe, but never blew a seal / gasket ever.

-

And I,d bet none of them did ....

Sean has always argued that folk should use the same settings / rules for dyno runs......he also posts videos of his HP runs......on u tube as well as faceache

He can be a bit marmite but If Private Pike says it makes xxx Hp then it makes xxx Hp ...

Totally agree Clive. I've no axe to grind or bury but i've known Sean for close to 15+ years and yes he can be a 1st class knob at times and we've had many, many discussions on ways of doing things - some things work, some don't (I had a Motec on my bike before he'd even see one, and dismissed mine as overkill!) but apart from trying to sell snow to the eskimos and sand to the arabs, he has made a name for well built turbo kits, primarily for late model sportbikes that will do what he says they will do, no doubts. They won't be cheap but HP never is and his come with guarantees - how rare is that.

For those that don't know there are 3 or 4 testing regimes for Dynos - uncorrected, SAE, DIN and the 'other one'. All will give a different number, even the dyno type affects the number - it could be electrically or water braked, light or heavy drum un-braked, acceleration type, they all give different numbers. So, yes be cautious of unproven numbers, but when they come from someone who really does 'what it says on the tin' don't be so dismissive. Results speak and there are some American teams racing with BigCC turbo kits and they ain't complaining of 'lack' of HP! Its actually nice to be able to say that the UK can build and export to the USA, a niche' product in a niche' marketplace and be well regarded!

-

Advantage is increase in oil pressure, reduction of oil temp by not passing oil through the hot block and avoidance of the notoriously leaky block / cases joint. Easy enough to do - tap hole M6 and add grub screws - job done.

-

1

1

-

-

A sharp hardened centre punch should be enough to flare out the pin sufficiently - deffo a 4 handed operation though.

-

For a stock bike with stock ignition, why not use Webmoto replacements - usually about £35 a piece as opposed to Dynas at £100 a pair with no advantage?

-

I had Barnett plates in my 1100K - was overbored and ran nitrous and the clutch was mint, upgraded to turbo and it went super grabby - not nice. Swapped back to std fibres and all good again - oh ...... was using a lock-up with both.

-

1

1

-

-

Most carb float needles won't withstand much above 2.5 - 3.0psi fuel pressure (usually lower) before leaking - remember most are only designed for gravity flow ie. virtually zero psi (relative to atmospheric). A compression tester is a start - a std say what now!? is about 160 - 200psi with no cylinder more than 10% drift against the others. This will indicate general cylinder state but there could be valve leakage and / or ring leakage - only definitive test is a leak down - not many workshops will have these but they are pretty foolproof as they'll show what is leaking, by how much and in each cylinder.....irrespective of any compression ratio

-

No piston is safe if the tune-up is wrong.................

BEST!!! bit of advice written here in a while!

-

1

1

-

-

<2bar I know is safe

I hope you meant to type 0.2 bar or about 2.5 - 3.0psi? Obviously a boost sensitive regulator is a requirement to add boost pressure to that setting. Certainly the FCR's are an unusual choice but they are about as good as possible using roller slides to prevent boost induced slide jamming. Smoking could have a few causes not necessarily turbo - fubar'd rings / bores through over fuelling is a possibility?

-

Looks ghetto - looks double hard - looks good!

-

-

Just wondering, when I put in the busa Pistons, will I need to change head gasket? And if so can I use standard head gasket or do I need special one to fit for the re-bore??

Really? What you you think? Std gasket is sized for a 78mm bore and you're making it 81mm - how much is hanging into the cylinder getting burnt to a crisp! There doing something on a budget and there just being cheap! Sorry if it sounds harsh - learn some basic principles before you grenade your motor!

-

1

1

-

-

A very helpful fella at universal turbos told me there is not enough material in a IHI turbo to machine out for a carbon seal.

one down !

Don't believe everything your told.............................http://www.smbaker.com/sand-rail/manx/rebuild-ihi-rhb5-and-add-carbon-seal

-

2

2

-

-

I guess it was conceived when those daft fat 300 section rear tyres were in vogue! Can't see the 6" offset front sprocket working though! Not to my taste but each to their own!

Gsx 1100 Pistons

in Air Cooled

Posted

Can't recollect any aftermarket turbo pistons being made that small ! Any markings on the underside? Just checked my APE catalog and Wiseco did a 76mm Turbo slug 7.8:1 CR so loads of boost potential!