-

Posts

5,425 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

Well that's an improvement - actual replacements and a bit cheaper than Suzuki San charges - (this one from a GSXR1000 K1 2001)

STRAINER - (15420-24FB0) - £47.23 each -

So do GSXR 1100 K L M & N - so whats the issue? (can't say for G H & J - never been into one! )

-

In that case i'd guess you maybe more 'sensitive' to a querk of the design ie. 'they all do it' but no one really notices, or its just a combination of elements that end up at your Right Hand ! ! ! A change of grip material may help?

-

1

1

-

-

In-Tank pre pump filters!

You need them to protect the pump but they are usually tiny micron level filtration and once blocked its 'good nite Vienna'

They can't be cleaned to any great degree or return to useful service and from what i've seen / experienced with others - they aren't a servicable part so whole assembly needs replacing . . . . . . . who'd have thought a WHOLE pump assembly would be a service item, designed for failure!

-

If it was tap on tank, I would have thought you'd feel it through your knees as well? Is the vibe constant or more / less at certain speeds or revs? Maybe wheel or other rotating pieces balance?

-

3 hours ago, Airhead-emmy said:

Hi All,

Have inherited an old GSX550 in parts from my father, which I am going to fix up and restore, only issue is that he hasn't heard the engine running for about 10-12 years.

Ideally I want to know the engine is good before I spend the time getting it all fixed up (Repainting everything, remaking a wiring harness as one at the moment is shagged, and fabricating the frame etc to make it into a bit more of a racer.)

I've taken the side off the engine block, and rotated it, and can feel / hear it compressing... But Ideally I wanted to make sure that 'trys to start' before I put all this time in.

My question is - What's the absolute bare bones I need wired up so I can hear it trying to turn over / seeing it spark?

Bonus points for any back of the fag packet drawing anyone could do

Thanks.

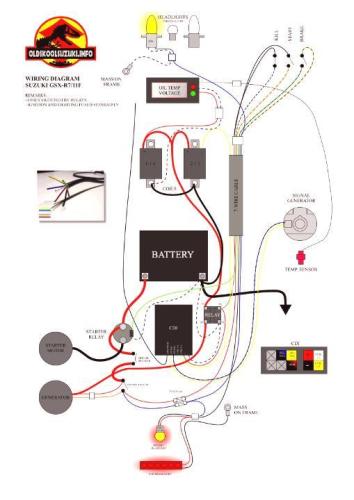

If you search you'll find this somewhere in the vault . . . . . . leave off anything connected to lights and horn and bingo!

-

2

2

-

-

Try it and see if it works for you? Are bars std or aftermarket?

-

White fluffy alloy is not a good look!

-

Use a glycerine filled gauge - then no issues.

-

1

1

-

-

With a GS / GSX you have the advantage of being able to use a timing light to get the base timing 'right' - the strobe should 'freeze' the timing mark through the hole in the plate. I never really bothered after setting the plate roughly in the middle of the slots - engines ran well enough so left well alone LOL!

-

1

1

-

-

3 hours ago, IhmeJanneFIN said:

Do you think stiffer valve springs would be a good idea, or can it be run as stock condition?

The whole of the valve train in my engine was developed by someone much smarter than me - Kroll Turbo grind cams, dual springs with probably increased poundage, Ti valve spring retainers and caps + other secret squirrel stuff. I'd say stock (good) springs would be ok for moderate boost but increased seat pressure is good insurance if getting into the 2 bar+ boost range.

-

On 9/1/2023 at 8:16 PM, davecara said:

Mines on standalone, I might try a 1250 ecu though i I can score one cheap enough. I don’t know what security is in them though, if they need the clocks/chipped keys or anything like that

Plus if they are anything like Busa engines, the crank position sensor is 'keyed' to the flywheel / rotor and there is a cam position sensor as well. All the info from these has to be at the right time / position else the ECU gets confused or won't work at all if one is missing! And there are very limited tuning avenues so you are pretty much stuck with stock fueling and ignition! Standalone's offer sooooooo much more flexibility and functionality - cheaper in the long run!

-

I'd use the 1100 shim head in a blown engine (I have on my 1460), shim spitting is unlikely due to lower RPMS. Bandit head would cost to put right, even if it could! A dot head wouldn't work at all well blown even with a decomp plate you lose the squish so burn suffers. Personally I'd use proper 81mm turbo pistons and sell the busa ones.

-

2

2

-

-

1 hour ago, bitzz said:

The 4 valve GSx bikes usually have a shell bearing bottom end and DO require oil pressure.

You want 30psi at idle and to gain 10psi for every 1000rpm to a max of about 80psi on a GSx.

See that's where you are wrong! Only the GSX750s had shell bearings - all the bigger engines retained roller bearings with corresponding low pressures (you'll never see 80psi in any of these)

-

" It won't make a noticable difference "

. . . . . . . . . really, it won't!

. . . . . . . . . really, it won't!

-

1

1

-

-

12 hours ago, Upshotknothole said:

As previously stated, you could ditch the coils and switch it to coil on plug, that'll remove 4 cables.

Oh yeah that'll make a HUGE difference from THREE wires with two coils to THREE (total) shared between four coils - all you lose is the spark leads but still have a load of wires dancing around over the cylinder head!

What is it with this obsession for wire and pipe free installations? All this shite has a reason for being there and the 'packaging' was designed by the OEM's to achieve that goal. Bikes ain't got the space to hide stuff unless you go really minimalist and hide wires in frame tubes etc. You can hide a certain proportion under the seat but it still has to reappear somewhere to be functional . . . . . . . fairings do more than just divert air ! ! !

-

2

2

-

-

Don't believe everything you see on UTube as gospel - a sizable proportion is posted by people who want to 'be a famous youtuber' but have little knowledge or understanding about what they host ! ! ! At least you've acknowledged the item you've bought is a 'knock off' Whether it works correctly only time will tell. And yes the modules are powered all the time as is the ignition coil - when in your case the ign. points are closed. When replacing the points with the DS3-2, a magnet takes over from the points and breaks the low tension windings in the coil/s which collapses the magnetic field inducing a voltage in the high tension windings that produces a spark. This happens REALLY quickly ie. 4 cyl bike @ 900 rpm idle the coil / s are being charged and discharged 15 times per second and obviously something like 165 times / second @ 10k rpm! Its also why ign. is powered 'key on' otherwise coils permanently 'on' would overheat and / or flatten the battery double quick time!

-

We know and we aren't on commission!

-

1

1

-

-

22 minutes ago, TonyGee said:

what year is your GSX engine ? 83's where mostly welded at the factory.

All SZ Katana's were built between 1980 - 1981/2 ie. the early ones 1074cc - the new models 1135cc were semi welded in the factory, although that can be improved upon!

Any tuning that improves the engines breathing and thus increases the torque, really needs a welded crank. Only a fool would try a turbo without prepping the bottom end and if the crank is being pulled apart swapping in 493 Katana rods is a damn good idea before re-assembly and fully welding the pins (thats where the skill is needed!)

-

1

1

-

-

May be ok but as the strainer has a bulge this may be designed to fit into sump pan in a certain way to maintain suction clearance - can't answer that, only you can.

-

Why the swap - Iridiums don't have much benefit unless you want to run super lean or your ignition system isn't up to scratch! Those don't look to have ever got hot enough to burn off the carbon - pretty sooty, not enough miles to colour the porcelain for a true read!

-

1

1

-

-

Can do but the extra pipe air volume may slow activation of the gate - a short line to the gate is preferred so a separate guage line from plenum is usual choice!

-

From my own experience #1 with a suck thro 1186 kit, 12.5:1 pistons and decomp plate and #2 draw thro EFI 1460 kit with 9.5 CR, the forged pistons can be quite forgiving in terms of higher CR with higher boost. With #1 it got abused with 9:1 CR 10lbs boost and 35 deg timing, #2 equally has had maybe 25-28psi forced in without any issues. If you keep the boost 'sensible' say in the 7-8psi range and maybe give the cams some overlap, you probably won't need to change the CR which also has the bonus of a nice engine off boost. Just my personal opinion - others may disagree!

-

2

2

-

-

I'd try 140 mains and see what the effect is and how much it changes the AFR and temps. Ultimately you may need more cooling!

Fuel pump/ flow problem

in Forced Induction

Posted

I thought there was another unserviceable one - how daft is that!