-

Posts

5,425 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

First question surely is 'what are you looking to get out of it? As this could / can determine what specification will suit. A suck thro aircooled with an HSR / S&S and knee burning dump pipe is about as oldskool as it gets and will do low to mid 200's with a reasonable amount of work (which would be required for a 'good' N/A engine anyway)

But as to your questions - I didn't know any other gears other than the 750 ones were available? It used to be them or stock - no options!. A freshened and preped crank will NEVER be cheap - this is where the oil boilers score! A/C rods, given the choice use 493 marked rods - known as Katana rods originally and used in many racing engines - again the oil boilers get a break as cheap std rods can take substantial hp increases. BTW I have BIG Cosworth pistons in my 1460 engine - not a 'usual choice' but they do the job.

-

1

1

-

-

How do you 'know' that they are low comp? They don't look to have a complete dish or is that raised portion just a photo artifact? It wouldn't need much of a thicker head gasket to make the 10.25's work in a blown application as they'd be classed as low comp for a NA build.

-

The spacer - thats the tricky bit to get right !

-

1

1

-

-

1 hour ago, Duckndive said:

It runs well one of Loopies creations ...

I figured it might have been from the sidecover. But as regards running 'well', the idle is all over the shop!

-

I wonder how well it actually works (if it works at all ! - show mock ups being a possibility) with a turbo blowing into a REALLY well undergeared supercharger ?

-

35 minutes ago, davecara said:

Behind the battery will still work as the cooler will have sufficient surface area to radiate heat but it wants to be in airflow really

Sort of true - airflow here is generally minimal and it's also a low pressure zone which won't help! My main cooler is under the seat but has a thermo switched fan due to lack of airflow.

-

27 minutes ago, Paulm said:

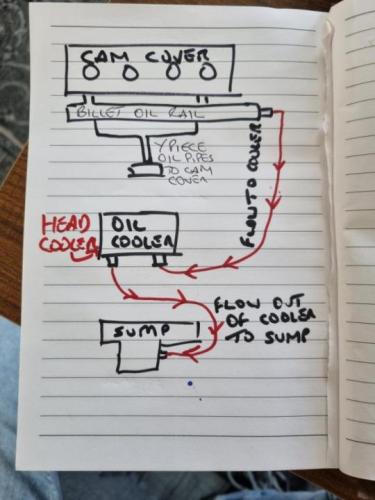

Going to fit a head cooler to my turbo GS over the winter,the oil flow will go as in the pic below,so oil to cooler out of cooler to sump as its going to be mounted behind my battery box,does the oil return need to be below the oil level or can it drain from a higher point on the sump? Anyone forsee any issues?

Your flows are backwards as the 'head cooler' isn't doing anything and if behind the battery, probably even less. Std. head cooling oil is bizarrely directly from the sump and not cooled at all so the head gets whatever temp that is in the sump. To improve this situation, oil should be routed from the former 'Y' (changed to a straight union) to a cooler (ideally located in good airstream ie. at front) with its other side split via a 'Y' or a 'T' into the rear cam cover ports, or in your case a single line to the billet oil rail. No return to sump is required as all returns are engine internally routed.

-

2

2

-

-

3 hours ago, Peris said:

Would it make sense to install Dynojet kit 1 when the carburetors are removed?

Bike is almost stock, There is only Yoshimura Rs 3 in place.

No - if you are on a budget then it would be a waste of money for a 'virtually' stock engine. With just a pipe / can the stock carburation should run exactly as . . . . . . . stock. Stripping and ultra cleaning of the carbs is the way to go - ethanol in fuel has a lot to answer for ! ! !

-

1

1

-

-

Most people would just be happy to shoot for between 10 - 12 thou. As regards that combination - all bets are off, and I don't want to know, how, why, when or where!

-

1

1

-

-

Whatever the workshop manual states or maybe +0.001" greater. Ring gap is more critical and that is what your figure refers to - if you honed the cylinder to 0.015 - 0.018", the piston would be like a cock in a sock . . . . . . ie LOOSE! If you are using aftermarket pistons, the manufr. will usually state clearence required which could be less than stock if low expansion alloy's have been used.

-

1

1

-

-

Don't bother with 'bling' as you'll generally never see it again after fitting - just get a known piece, fit and forget. At the power levels you are looking for, I'd fit a 12mm M6 screw and locknut on 3 of the arms and try it - unlikely you'll need all 6 but its possible + start with fresh Suzuki fibres and it should be mint!

-

1

1

-

-

I remember Sean @ BigCC had a Dom Trickett EFE head done with equal sized inlet and exhaust valves, fully ported both sides as he figured getting the exhaust out was maybe more important whilst the intake was forced in. As far as I know it lasted barely a few dyno pulls as it just didn't work so got off'd into the pile of failed experiments LOL! Conversely, a big valve will pay off if running big boost if only to minimise ANY potential airflow restriction.

-

1

1

-

-

5 hours ago, Upshotknothole said:

Those look like DJ needles, they should be titanium. Not sure if DJ ever did a kit for the 40mm carbs, since we didn't get them in the states. Factory Pro I think made jet kits for them if you should ever decide to use them.

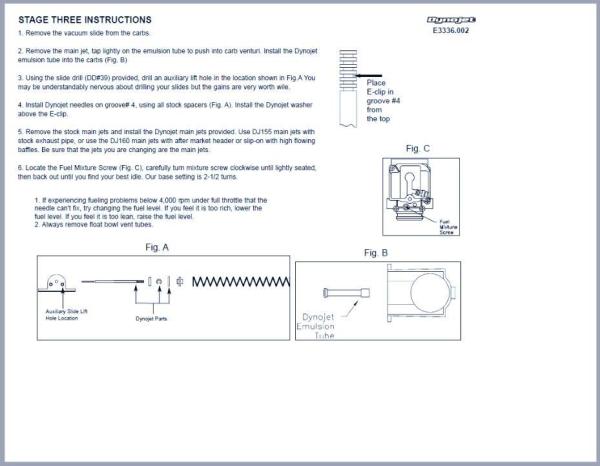

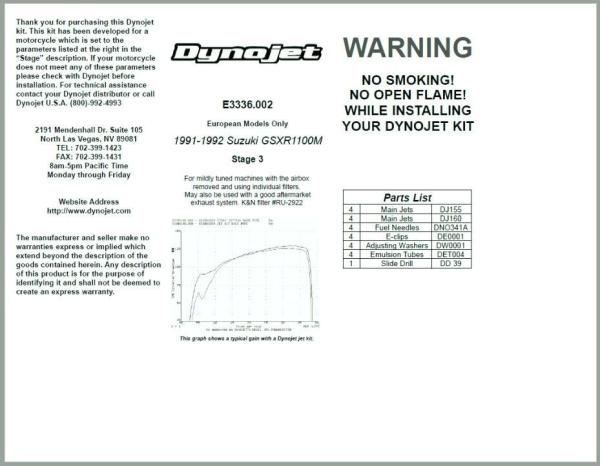

Yes they did, here is the reference - E3336.002 - Euro models only (for obvious reasons) I'm not sure they are Ti - more like hard anodised aluminium. A Ti made needle would not wear like the one shown. Compare to the steel OEM which has virtually no wear and Ti is tougher than steel for abrasion wear!

13 hours ago, caferacer175 said:OK, so you think the length and shapes of needles are right??

First needle on pic is original (from another gsxr 1100 89), second needle ˇoriginalˇ dynojet when I bought bike and the rest needles are from new dynojet kit.

Dunno what that 2nd needle is from but it ain't for a GSXR1100 K / L ! The other 4 are deffo for 36mm CV's on a GSXR1100 K/L 1127cc.

-

2

2

-

-

1 hour ago, Captain Chaos said:

EU 1991 gsxr1100 has 40mm carbs

He's not wrong and can't tell from the pic if 40s are fitted or not. If they are. . . . well there's your problem LOL

-

1 hour ago, Duckndive said:

Given all the probs folk seem to have with the Hydraulic Operation

I'm thankful I've always used cable operation on oil boilers

I've never had a problem, even swapping diaphragm to spring and spring with lock-ups - fill. bleed, work! Only thing I needed to do with clutch swap is add a 6mm ball bearing over the push rod - couldn't be arsed to make a new one as it just worked!

-

1

1

-

-

Those look like the ones I used - 1186 bore, 4-2-1 V&H Supersport Dual pods 136 & 138 MJ - set-up on dyno 144 rwhp. Have you done the whole conversion inc the slide holes? Mine worked fine from the get-go, just dyno'd to fine tune!

-

It was 30+ years ago - maybe they put their sensible head on and changed the threads?

-

1 hour ago, gorbys said:

What do you mean? I have dj mains in my 1100 with the stock tubes.

Mikuni's being Japanese have metric threads, Dynojet being American will have Imperial / peculiar threads - draw your own conclusions! Tried it once and jet tightened up before fully done up so stuck with stock in stock and DJ with DJ!

-

DJ Mains won't fit in Mikuni Emulsion tubes. Most steel aftermarket pipes with chrome tubes will blue at first bend from head. And the Mains are flowing fuel up the emulsion tubes that is metered by the needle which never completely leaves the tube, so to say they are separate is incorrect.

-

Google is your friend . . . . . . . eventually !

Note this is for use with 40mm carbs - thats why the MJ sizes are so massive! I used a kit for the K & L (36mm carbs) on a 1186cc bored engine and only needed 136/138 DJ mains ! The air flow through the 40's is just too slow hence why you need massive MJ's!

Its annoying that pdf's aren't allowed as attachments ! ! !

-

Not really - its only really open at idle and low speed and the whole inlet from air filter through turbo to plenum will be at atmospheric pressure once valve has opened - plenty air for normal NA operation. Plus its unfiltered air so not good in dirty climates !

-

1

1

-

-

4 hours ago, latheboy said:

its already potentially "breathing" through the bov at idle.

As it should be - any vacuum present should be sufficient to open the valve - which means any time pre boost.

-

Yeah I would just to be sure!

-

1

1

-

-

You can reuse as they will wear in to the new bores but if close to lower tolerance there is the chance that when worn a bit they'll be out of spec?

-

1

1

-

Air cooled bottom end.

in Forced Induction

Posted

If thats your intention then use a GS1150 / EFE crank and rods - try and find a good one, save on pulling it apart, if the bearings are good just weld up the pins fully and be done with it! Spending £1500+ on a crank for sub 200hp doesn't make sense . . . . . . . . unless you get boost addicted ! ! ! As Clive says its usually detonation that kills engines, that or oil problems. Start fat on fuel and safe on ignition and use a dyno to creep up on optimal but don't try for a 'little bit more' - you have been warned!